Introduction to CNC Machining in the Energy Sector

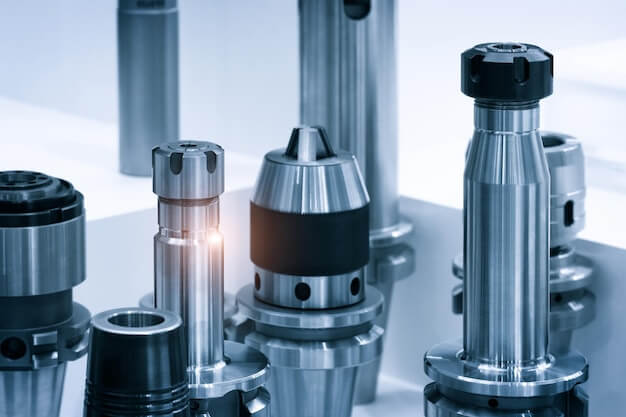

CNC (Computer Numerical Control) machining stands as a pivotal technology in the energy sector, enabling the precise fabrication of components essential for energy systems. This process involves the use of computers to control machine tools, ensuring high levels of accuracy and efficiency. In the energy sector, CNC machining is crucial for producing parts for wind turbines, solar panels, and other renewable energy technologies. It allows for the creation of complex shapes that are difficult to achieve with manual machining, contributing significantly to the advancement and reliability of energy systems. For example, the precise blades of wind turbines, which are critical for maximizing energy production, are often manufactured using CNC machining techniques.

Common Challenges in Material Selection

Choosing the right materials for energy applications presents several challenges. One main difficulty lies in finding materials that can withstand the extreme conditions often encountered in the energy sector, such as high temperatures and pressures. These conditions demand materials with exceptional durability and resistance to degradation over time. For example, in the context of turbine blades in power plants, the material must not only tolerate high temperatures but also maintain its structural integrity under constant exposure to aggressive environments. This necessitates a careful balance between material properties such as thermal stability, mechanical strength, and corrosion resistance. The selection process becomes even more complex when considering the need for cost-effectiveness and sustainability, making it a rigorous task to identify materials that meet all these criteria without compromise.

Criteria for Material Selection in CNC Machining for the Energy Sector

When selecting materials for CNC machining in the energy sector, two critical criteria must be considered to ensure both efficiency and reliability. First, durability is paramount; materials must withstand harsh environmental conditions, such as extreme temperatures, corrosion, and wear over time. For example, stainless steel is often chosen for its resistance to corrosion and strength at high temperatures. Second, the efficiency of the material contributes significantly to the energy production process. Materials with high thermal conductivity, like copper, are preferred for components that require quick heat dissipation. This dual focus on durability and efficiency ensures that the machinery operates smoothly, with minimal downtime and maintenance requirements, thereby optimizing the energy production process.

- Durability: Endure harsh conditions

- Efficiency: Contribute to energy production efficiency

Popular Materials in CNC Machining for the Energy Sector

When it comes to CNC machining for the energy sector, some popular materials include:

- Stainless Steel: Known for its corrosion resistance and durability, stainless steel is a preferred choice for components in the energy industry.

- Aluminum: With its lightweight and excellent thermal conductivity, aluminum is widely used in energy applications for its efficiency and reliability.

- Titanium: Recognized for its high strength-to-weight ratio and resistance to corrosion, titanium is suitable for demanding energy sector requirements.

Case Study: Material Selection for a Wind Turbine Component

The focus of this case study is on the material selection for a critical wind turbine component: the turbine blade. The turbine blade plays a pivotal role in converting wind energy into mechanical energy, which is then transformed into electricity. The selection of material for this component was guided by the need for:

- High strength-to-weight ratio: To ensure efficiency in energy conversion and durability against variable wind speeds.

- Corrosion resistance: To withstand harsh environmental conditions without degrading.

- Flexibility: To allow for some bending without breaking, accommodating stress and strain during operation.

After thorough analysis, a composite material made primarily of fiberglass and reinforced with carbon fiber was chosen. This material meets the criteria by offering an exceptional strength-to-weight ratio, ensuring durability and performance efficiency. Its corrosion resistance guarantees longevity, and the inherent flexibility of the composite material allows for optimal operational resilience. This choice underscores the importance of material properties in achieving both efficiency and reliability in wind turbine components.

Future Trends in Material Selection for Energy Applications

The evolution of materials for energy applications is pivotal for enhancing efficiency and reliability within the energy sector. Emerging materials and technologies are at the forefront of this transformation. Innovations such as high-temperature superconductors, lightweight composite materials, and advanced ceramics are set to redefine energy systems. High-temperature superconductors, for instance, promise significant improvements in electrical transmission efficiency, potentially reducing energy loss over long distances. Lightweight composites contribute to the efficiency of wind turbines by offering enhanced strength-to-weight ratios, leading to larger, more efficient blades. Advanced ceramics are being explored for their exceptional heat resistance in nuclear reactors, which could improve safety and efficiency. These developments not only promise to improve the operational efficiency of energy systems but also contribute to their reliability and sustainability, marking a significant shift in the material landscape for the energy sector.

- High-temperature superconductors for improved electrical transmission efficiency.

- Lightweight composite materials for more efficient wind turbine blades.

- Advanced ceramics for enhanced heat resistance in nuclear reactors.

Other Articles You Might Enjoy

- Maximizing Efficiency in CNC Machining: The Role of Light-Weight Metals

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the automated control of machine tools by means of a computer. This technology…

- The Future of Medical Device Manufacturing: CNC Machined Stainless Steel

Introduction to Medical Device Manufacturing Medical device manufacturing is a crucial sector in the healthcare industry, powering a myriad of medical procedures and treatments worldwide. This field involves the design,…

- Precision CNC Machining for High-End Audio Equipment

Precision CNC Machining in High-End Audio Equipment Manufacturing Precision Computer Numerical Control (CNC) machining refers to a highly-advanced technology where computer-generated codes are used to operate factory machinery and tools.…