Evaluating the Efficiency of Composite Materials in High-Precision CNC Machining Environments

Composite materials are an aggregation of two or more distinct substances that, when combined, result in a material with different physical or chemical properties. These unique attributes make them ideal for use in CNC machining, a process used to manufacture parts by means of precisely programmed commands rather than human-guided manual control.

In high-pressure environments like those found in aerospace, automotive and manufacturing industries, the efficiency of these composite materials is critical. Evaluating this efficiency enables improved outputs, cost-effectivity, durability, and overall performance, thus contributing significantly to operational excellence.

- Composite materials: Aggregates of multiple distinct substances combined to form one substance with unique chemical and physical properties.

- CNC machining: A manufacturing process involving computer-coded instructions for precise control over equipment.

- High-pressure environments: Situations characterised by intense stress/pressure often found within industries such as aerospace and automotive production.

Therefore, comprehensive understanding of how such composites behave under specific conditions is crucial not only from a technical perspective but also for optimizing resource allocation and achieving economic sustainability.

Understanding Composite Materials

In the realm of high-pressure CNC machining, composite materials play a pivotal role in enhancing productivity and efficiency. Essentially, composite materials are multifaceted constructs made up of two or more different types of substances which typically possess diverse physical and chemical properties. These substances when combined, create a material that has superior characteristics in terms of strength, durability, resistance to heat, corrosion, etc., hence making them invaluable for manufacturing industries such as CNC machining.

A perfect exemplification of this would be Carbon Fiber Reinforced Polymers (CFRP), a common type of composite material extensively used in CNC machining. CFRP is constructed through weaving carbon fiber cloth strands with an epoxy resin, thus creating a product that exhibits remarkable strength-to-weight ratio, rigidity, fatigue resistance, and dimensional stability. Designed to withstand wear-intensive operations, CFRPs considerably augment the lifespan of machine parts while simultaneously boosting their performance.

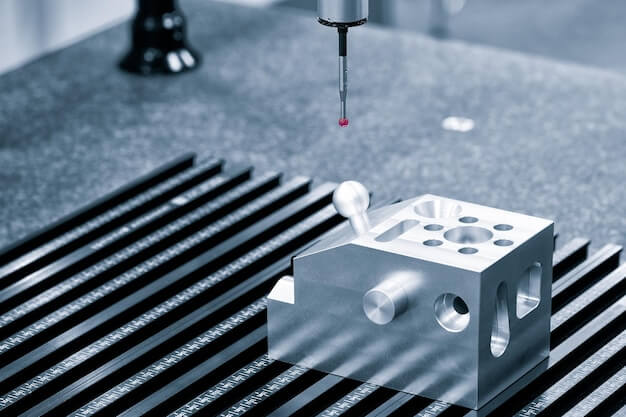

Overview of High-Pressure CNC Machining

High-pressure CNC machining requires the use of composite materials that can withstand extreme forces and maintain dimensional stability. The efficiency of composite materials in high-pressure CNC machining environments is crucial for achieving precise and durable components. By leveraging advanced CNC machining techniques and high-quality composite materials, manufacturers can ensure the production of reliable parts that meet the stringent requirements of high-pressure applications.

Evaluation Criteria for the Efficiency of Composite Materials in High-Pressure CNC Machining

Efficiency is a crucial aspect when utilizing composite materials in high-pressure Computer Numerical Control (CNC) machining environments, and it’s critical to establish fair criteria to assess their performance. In this context, the evaluation process primarily involves assessing the relative resistance to wear under high pressure, longevity of the composite material, its machinability, as well as the dimensional stability during and after machining.

Ranging factors influence the efficiency and performance of these materials; hence, an effective methodology addresses each one systematically. The impact factors include:

- The construction of the composite material: This refers to how the various elements are combined into a cohesive whole. Different types of synthesis result in dissimilar physical and chemical properties impacting the actual efficiency.

- The operating conditions: These involve temperature, external forces’ intensity and distinctiveness, vibration levels among others. Each condition can significantly affect the throughput and effectiveness of the composite materials in CNC machining.

- The nature of high pressure: Depending upon whether the pressure exerted on the composite material is constant or fluctuating over time affects the overall endurance and functionality profoundly.

In essence, by evaluating composite materials appearing within such settings, we capture a holistic view of their potential and suitability in meeting diverse demands hence enabling optimized resource allocation and improved product quality.

Impact of Efficient Composite Materials

Efficient composite materials have significantly improved CNC machining processes, primarily through increased durability and resource reduction. By their very structure, composites are designed to handle high pressure environments better than many traditional materials.

The use of carbon fiber-reinforced polymer (CFRP), for instance, demonstrates the considerable impact such materials can deliver. This lightweight yet sturdy material increases tool longevity and reduces vibration during processes, despite intensive usage over extended periods.

- The CFRP example illustrates how efficient composites minimize wear and tear on machine parts. Improved life span of machinery equals lower replacement costs and reduced downtime.

Another notable example is the utilization of glass-fiber reinforced polymers in precision engineering applications. Such materials offer a superior strength-to-weight ratio compared to metals, enhancing accuracy while boosting resistance towards deformation.

- The benefit here is twofold: efficiency improvement leads to higher-quality outputs, and greater resistance means fewer instances of costly error correction or rework.

Challenges and Solutions in Utilizing Composite Materials in High-Pressure Environments

In the realm of high-pressure CNC machining, the use of composite materials signifies a considerable amount of complexity. One significant challenge is that these materials have anisotropic properties. Unlike metals, they possess different strengths, stiffnesses or conductivities based on directionality leading to unpredictable performance under high pressure.

Potential issues also involve delamination – layers peeling away due to stress points can cause immediate catastrophic failure. Additionally, these composites are subjected to thermal degradation causing undesirable alteration in mechanical and physical properties such as strength and durability. They also demonstrate poor shock absorbency which can lead to structural damage over time in high-vibration environments.

Solutions recommended includes using hybrid composites that reduces material weakness and increase resilience against high stresses. Enhanced design optimization strategies concentrating on stress transfer analysis could minimize issues like delamination.

Furthermore, preventative measures, such as reinforcing the composite structure with strong fiber materials and utilizing improved thermal management systems can aid in mitigating effects of thermal degradation. Lastly, developing advanced damping techniques can help combat problems related to low shock absorbency.

Advancements in Strengthening Composites for High-Pressure Environments

The current wave of technological innovations has brought significant improvements to the way composite materials resist high pressure, especially in CNC machining environments. Advancements in this field aim at enhancing the structural integrity and hardness of composites, such as the integration of nano-fillers like graphene and carbon nanotubes within the matrix of the composite material. These nano-fillers improve the ability of composites to withstand extreme pressure without deformation.

- Improved Pressure Resistance: The recent advancements have led to more extensive utilization of Ultrahigh Molecular Weight Polyethylene (UHMWPE) composites reinforced with Multiwalled Carbon Nanotubes (MWCNTs). This combination offers exceptional mechanical strength and resilience against high pressure.

- Potential Impact on CNC Machining Practices: These advancements are anticipated to remodel future CNC machining practices, prompting a shift towards composites capable of maintaining optimum performance under intense pressure. Embracing these highly resistant composites may translate into longer tool life cycles, increased efficiency, and reduction in operation costs due to lesser wearing-out and subsequent replacements.

In conclusion, identifying the specific requirements of each machining job and selecting suitable advanced composites can ensure sustained efficiency even under rigorous high-pressure conditions in the CNC machining environment.

Other Articles You Might Enjoy

- Unraveling Bead Blasting in CNC Machining(die casting Agatha)

Bead blasting is a procedure that's widely used in the sector of Computer Numerical Control (CNC) machining. This process involves forcefully propelling a stream of abrasive beads under high pressure…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Revolutionizing CNC Machining with Bead Blasting(die casting Laurel)

Bead blasting, as a critical aspect of modern manufacturing methods, can boost the overall quality and functionality of various components. This technique has proven incredibly beneficial in Computer Numerical Control…

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu