The process of computer numerical control (CNC) machining has been a vital aspect of the manufacturing industry for years, providing precise and repeatable results on various mediums including lightweight metals. In particular scenarios, it may be necessary to remove chrome from these surfaces before or after the machining process. Whether you’re dealing with excess coating or trying to achieve a certain aesthetic appeal, learning how to effectively eliminate this layer is an essential skill.

How CNC Handles Lightweight Metals

In numerous industries, such as automotive and aerospace, lightweight metals like aluminum are preferred due to their combined strength and lightness. Despite their relatively low density, these metals can withstand high stress levels making them ideal for intricate parts.

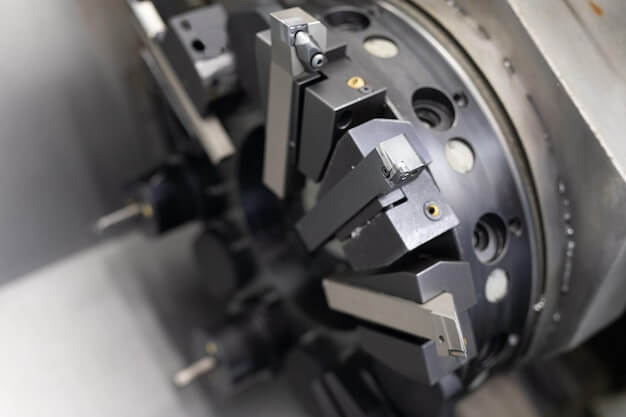

CNC machining is particularly apt for working with lightweight metals. The whole cutting, drilling, or sculpturing process is automated through pre-programmed software. This results in designs that boast impressive accuracy and consistency, even when carving out micro details.

Importantly though, several lightweight metals come finished with a chrome layer. While this enhances aesthetics and adds corrosion resistance, there might be circumstances where its removal becomes necessary.

Understanding Chrome Plating on Metals

Chrome plating represents one prevalent finishing procedure on lightweight metal components due to its beneficial properties – increased hardness, reduced friction, heat resistance, and improved cleanliness. Yet, specific instances require its elimination, but removing chrome isn’t as simple as scraping off paint, especially without damaging the underlying material.

Using Chemical Stripping

One common method employed by professionals to remove chrome from metal in industrial setups involves chemical stripping. It involves submerging the part into a container filled with chemicals specifically designed to remove chrome without affecting the base metal.

For safety reasons, this process should ideally occur under expert supervision. Workers must wear appropriate personal protective equipment, including gloves and goggles, because some stripping solutions contain dangerous substances that could harm the skin or eyes.

Implementing CNC Machining

CNC machining, although primarily utilized to alter forms and shapes of metal components, can be tweaked for chrome removal. The process necessitates adherence to stringent settings with utmost precision to avoid damage to the underlying lightweight metal material.

For this purpose, machinists use coated carbide tools that are known to withstand the hardness of chrome finishes while gently peeling it off the base layer. Operating at low speeds ensures minimal stress on the machine parts whilst providing a clean and smooth finish post-removal. This approach would involve programming the CNC machines to remove just the chrome amount without delving into the actual metal portion.

The Importance of Expertise

Removing chrome from lightweight metals in CNC machining is a crucial yet complex task demanding a combination of technical understanding, right equipment, strict safety protocol adherence, and skilled expertise.

There’s no hard-and-fast rule actually. Each project entails unique variables such as the precise type of lightweight metal involved, chrome thickness, and targeted end-results impacting the optimal chrome removal method.

Nevertheless, mastering the art of chrome removal expands the versatility and maneuverability of CNC machining services, facilitating refined control over product aesthetics, function, and longevity. As we advance deeper into a more automated world filled with intricate designs, possessing comprehensive knowledge about processes like these will undoubtedly level up your game within the competitive industry sector. So, keep practicing, learning, perfecting, and innovating!

Other Articles You Might Enjoy

- CNC Machining: Mastering Chrome Removal From Lightweight Metals(non ferrous metals Moses)

CNC (Computer Numerical Control) machining plays an indisputable role in various industries, notably for its unrivaled precision and ease of production. A common application is the production of lightweight metals…

- CNC Machining in Microelectronics: Material Precision for Component Miniaturization

Introduction to CNC Machining in Microelectronics CNC (Computer Numerical Control) machining stands as a cornerstone in the realm of microelectronics, offering unparalleled precision in the fabrication of components. This technique…

- Advances in CNC Machining: Using Ultra-Hard Materials for Precision Parts

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise creation of parts by controlling machine tools via computer. This technology…