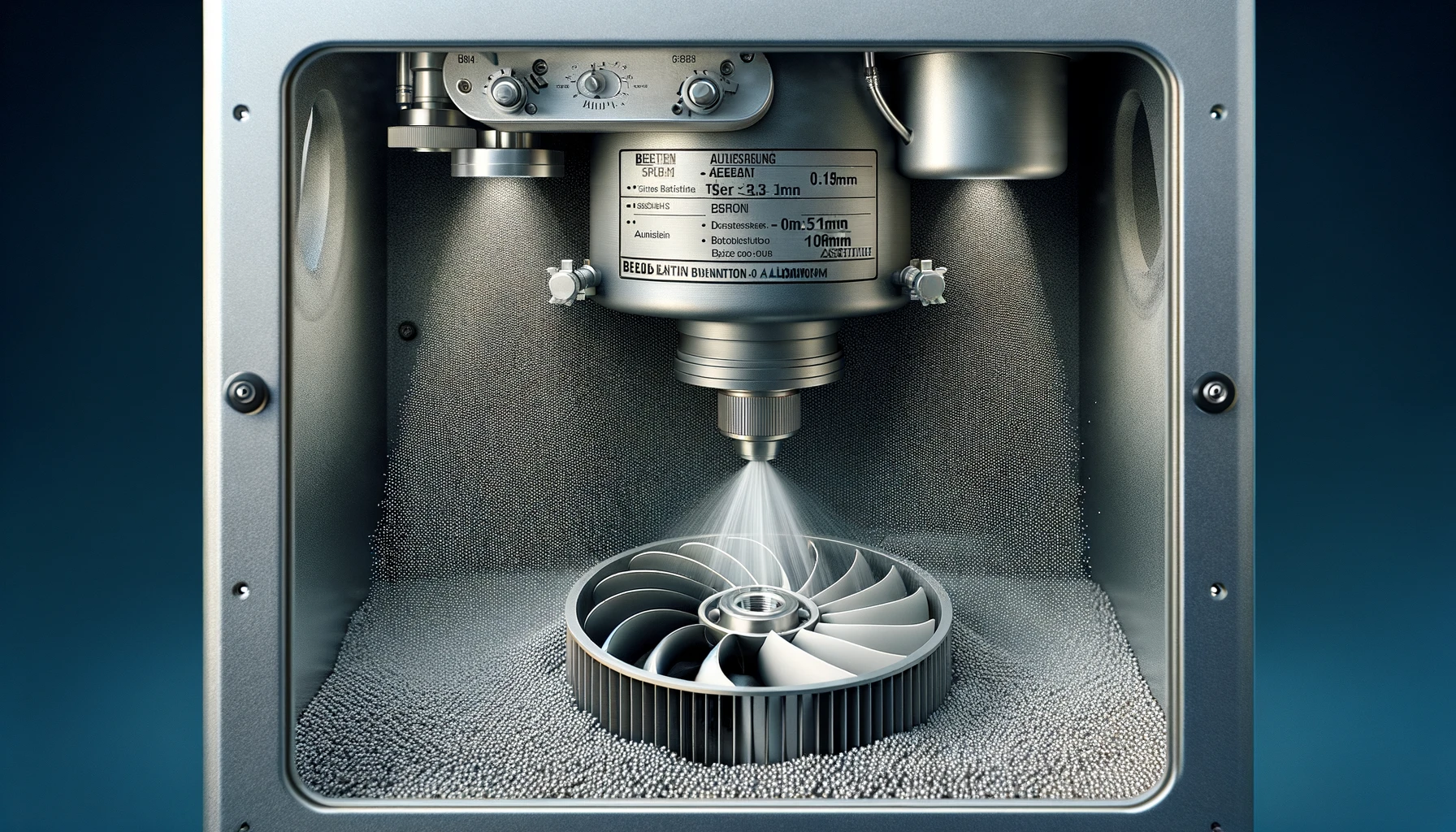

Overview of Bead Blasting and Its Importance in CNC Machining

Bead blasting stands out as a pivotal surface treatment in the realm of CNC machining, offering a blend of aesthetic enhancement and functional improvement to machined parts. This process involves propelling fine glass beads at a high velocity towards the surface of a workpiece, which results in a clean, uniform, and matte finish. Particularly in industries where precision and surface quality are paramount, such as aerospace, automotive, and medical device manufacturing, bead blasting is instrumental in achieving the desired surface characteristics without compromising the integrity of the workpiece.

Analysis of Bead Blasting’s Impact on the Surface of CNC Machined Parts

The impact of bead blasting extends beyond merely altering the visual appearance of CNC machined parts. At a microscopic level, bead blasting modifies the surface topology, inducing beneficial compressive stresses that enhance the fatigue resistance of the component. This alteration in surface properties is crucial for parts subjected to cyclic loading conditions, where fatigue failure is a potential risk.

Case Study: A prominent aerospace component manufacturer reported a significant improvement in the lifespan of their turbine blades after incorporating bead blasting into their finishing process. The blades, subjected to rigorous operational conditions, exhibited enhanced resistance to stress-corrosion cracking, attributed to the compressive stresses imparted by the bead blasting treatment.

The Influence of Working Parameters on Bead Blasting Outcomes

Optimizing the working parameters of bead blasting, such as bead size, air pressure, and blasting duration, is essential for achieving the desired surface finish and material properties. These parameters directly influence the extent of surface coverage, the depth of the induced compressive layer, and the overall uniformity of the treatment.

- Bead Size: Smaller beads are typically used for finer finishes but may require longer blasting times to achieve full coverage.

- Air Pressure: Higher pressures increase the kinetic energy of the beads, resulting in more aggressive material removal and surface compression.

- Blasting Duration: Longer blasting times can ensure thorough coverage but also risk over-processing, which might lead to surface damage or dimensional inaccuracies.

Measuring and Regulating the Granularity and Speed in Bead Blasting

Granularity and speed are pivotal parameters in bead blasting, directly affecting the surface finish and integrity of the CNC machined parts. Precise measurement and control of these parameters allow for a consistent and optimal finish, minimizing surface defects and ensuring the structural integrity of the part.

Granularity, or bead size, influences the smoothness and texture of the finish. Smaller beads achieve a finer finish but may require more time to cover the same area. Speed, determined by the velocity of the beads and the air pressure driving them, impacts the force with which the beads strike the surface, affecting both the rate of material removal and the depth of the surface compression.

Optimizing Working Parameters to Enhance Efficiency and Quality in Bead Blasting

Optimization of bead blasting parameters is not a one-size-fits-all process; it requires careful consideration of the specific requirements of each part and material. For instance, softer materials might necessitate lower air pressure to prevent surface deformation, while harder materials could withstand higher pressures for a more pronounced effect.

| Air Pressure (PSI) | Surface Roughness (Ra, µm) | Compressive Stress (MPa) | Blasting Time (minutes) |

|---|---|---|---|

| 30 | 1.2 | 50 | 5 |

| 40 | 1.0 | 100 | 4.5 |

| 50 | 0.8 | 150 | 4 |

| 60 | 0.6 | 200 | 3.5 |

| 70 | 0.5 | 250 | 3 |

| 80 | 0.4 | 300 | 2.5 |

| 90 | 0.3 | 350 | 2 |

| 100 | 0.25 | 400 | 1.5 |

Deciphering the Crucial Working Parameters in Bead Blasting

Understanding the interplay between different working parameters and their effect on the final outcome is crucial for mastering bead blasting. This involves not only the direct parameters, such as bead size and air pressure but also the angle of incidence and the distance between the nozzle and the workpiece.

| Blasting Angle (Degrees) | 5 cm Distance | 10 cm Distance | 15 cm Distance | 20 cm Distance | 25 cm Distance |

|---|---|---|---|---|---|

| 30 | 1.0 µm | 1.2 µm | 1.4 µm | 1.6 µm | 1.8 µm |

| 45 | 0.9 µm | 1.1 µm | 1.3 µm | 1.5 µm | 1.7 µm |

| 60 | 0.8 µm | 1.0 µm | 1.2 µm | 1.4 µm | 1.6 µm |

| 75 | 0.7 µm | 0.9 µm | 1.1 µm | 1.3 µm | 1.5 µm |

| 90 | 0.6 µm | 0.8 µm | 1.0 µm | 1.2 µm | 1.4 µm |

Enhancing Efficiency and Quality in Bead Blasting through Parameter Optimization

Efficiency and quality in bead blasting are closely tied to the optimization of various working parameters. By systematically adjusting and testing these parameters, manufacturers can find the sweet spot that yields the best surface finish in the shortest time, with minimal wear on the equipment and minimal material waste.

Case Study: An industrial valve manufacturer implemented a systematic approach to optimize their bead blasting process for stainless steel valves. By adjusting parameters such as bead size, air pressure, and blasting time, they achieved a 20% improvement in surface finish uniformity and a 25% reduction in processing time, significantly enhancing their production efficiency and product quality.

Case Studies: Illustrating Successes and Deriving Insights

Real-world applications of optimized bead blasting processes provide valuable insights into its benefits and best practices. These case studies highlight the adaptability of bead blasting to various materials and products, showcasing its role in improving product lifespan, performance, and aesthetic appeal.

- Aerospace Gears: A leading aerospace company optimized bead blasting for titanium gear components, resulting in a 40% increase in fatigue life due to improved surface compressive stresses.

- Medical Implants: A medical device manufacturer fine-tuned bead blasting parameters for cobalt-chrome knee implants, achieving a smoother surface that enhanced osseointegration and patient outcomes.

- Automotive Suspension Parts: By optimizing bead blasting for aluminum alloy suspension parts, an automotive supplier enhanced the corrosion resistance and visual appeal of their products, leading to increased customer satisfaction and demand.

These case studies demonstrate the transformative impact of bead blasting when optimized for specific applications, underscoring its importance in modern manufacturing processes.

Other Articles You Might Enjoy

- Surface Refinement: Leveraging Bead Blasting for CNC Machining

In the realm of CNC machining, surface quality plays a pivotal role in determining the overall performance and aesthetics of the final product. Leveraging bead blasting as a surface refinement…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu