In the dynamic world of computer numerical control (CNC) machining, bead blasting is a pivotal process that contributes significantly to the quality and appearance of machined products. It’s frequently used as an effective finishing method within various industries, including automotive, aerospace, and more.

Bead blasting involves forcibly propelling a stream of abrasive beads against a surface under high pressure to enhance its finish by way of removing surface contaminants or creating a desired texture. Its versatility lies in its capacity to remove cosmetic inconsistencies without altering the dimensions of the piece.

Why Bead Blasting?

The value of bead blasting becomes apparent when considering both functionality and aesthetics. On the functional side, bead blasting can clean surfaces of tiny imperfections, such as burrs, which might otherwise interfere with product assembly or performance.

On the aesthetic front, this remarkable technique leaves a uniform matte or satin-like finish on components. This not only provides an elegant appearance but also helps conceal any minor scratching or wear that may occur during use.

The Process of Bead Blasting

Understanding how bead blasting works in CNC machining boosts appreciation for this essential technique.After a component has been designed using CAD software and passed through standard machining processes—such as milling, drilling or turning—it then moves on to post-processing treatments like bead blasting.

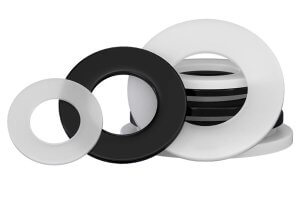

Introducing pressurized air into the system powers the flow of bead media towards the workpiece. The operator adapts varying nozzle angles to ensure optimal exposure while maintaining the integrity of the design details. Beads made from materials like glass, ceramic, and steel are commonly used due to their durability and efficiency.

Material considerations play a critical role in achieving preferred results; softer metals require gentler media, whereas tougher materials allow for aggressive bead types. Considering the texture and hardness of the target material allows the determination of ideal machine settings and choice of appropriate bead media – factors crucial for a successful blasting operation.

Bead Blasting and CNC Machining

In scenarios where strict tolerances are not the priority, but aesthetic appearance is desired—prominent in cases like architectural models or prototyping—bead blasting plays an invaluable role. Despite its seeming simplicity, it requires expertise to evaluate the correct bead size, shape, hardness, and pressure levels required to accomplish the envisioned results without jeopardizing the piece’s functionality.

From small-scale backyard parts manufacturers to industrial-grade production lines, bead blasting is at the forefront due to the improved product quality it offers by adding the finishing touches to CNC machined components.

Moreover, bead blasting is environmentally friendly. Used effectively, it aids the longevity of machinery, while minimizing hazards associated with some chemical cleaning processes used in removing surface contaminants.

Final Thoughts

The incorporation of bead blasting into CNC machining processes can dramatically uplift the overall product quality – esthetically pleasing, cleaner finished products that meet defined standards of consistency and tolerance. With rapidly advancing technology and increased demand for superior finishes on manufactured products, mastering bead blasting becomes an essential investment.

As we continue to explore the expansive domain of CNC machining, honing technical proficiencies such as bead blasting helps set apart the ordinary from the exceptional, offering diverse application possibilities while simultaneously illustrating the remarkable potential within this thrilling manufacturing arena.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…

- Nickel vs. Cobalt Alloys in High-Temperature CNC Machining: A Detailed Analysis?

Nickel and Cobalt Alloys in High-Temperature CNC Machining Both Nickel and Cobalt alloys play an essential role in high-temperature CNC machining. These metal alloys are popular choices due to their…