Introduction: Why Choosing the Right Metal Cutter Matters in CNC Machining

When I first started exploring CNC machining, I quickly realized that not all cutting tools are the same. The Metal Cutter you pick has a direct impact on the results you achieve. The wrong choice can lead to slower production, tool breakage, poor surface finish, or even scrapped parts. By understanding the fundamentals of Metal Cutters and their role in CNC operations, it’s possible to streamline workflows, reduce costs, and consistently produce high-quality components.

A Metal Cutter is not just a random piece of hardware. It’s often a carefully engineered tool designed for specific materials, shapes, and cutting conditions. Some cutters handle aluminum beautifully, allowing fast feeds and bright finishes. Others are built to conquer challenging alloys, providing smooth cuts in tough materials. The complexity of modern industry means that we have a vast range of Metal Cutters—from simple end mills to sophisticated laser cutters—all aimed at meeting different needs.

In CNC machining, precision and repeatability matter. The right Metal Cutter and well-chosen parameters can achieve tolerances measured in thousandths of an inch. Without the right tool, though, even the most advanced CNC program might result in subpar parts or wasted stock.

This guide aims to shed light on how to select and use the best Metal Cutter for your CNC operations. I’ll cover tool types, material considerations, parameter optimization, problem-solving, trends, and real-world examples. Whether you’re new to CNC or looking to refine your approach, this comprehensive look at Metal Cutters will serve as a roadmap to better machining outcomes.

Types of Metal Cutters and Their Applicability in CNC

When I first tried to improve my CNC machining skills, I discovered that the world of the Metal Cutter is huge. There’s no single universal cutting tool that works perfectly for every situation. Instead, there’s a broad range of Metal Cutters, each designed for specific applications, materials, and precision levels.

Understanding the variety of Metal Cutters out there is the first step toward making better decisions. Once you know the differences, it’s easier to pick the right tool. With CNC machining, we rely on programmed instructions to guide a Metal Cutter along a toolpath. But the best code in the world won’t help if the cutter isn’t appropriate for the job.

From Manual to Industrial-Grade

A Metal Cutter can be as simple as a handheld hacksaw or as advanced as a high-powered laser beam. Let’s start with the basics:

- Manual Metal Cutters:

Tools like hack saws, bolt cutters, or tin snips are the simplest form of Metal Cutters. They rely on muscle power. While I don’t typically associate these with CNC machining, I list them here to show the broad spectrum. Sometimes, these tools come into play for rough prep work before a part moves to a CNC stage. - Power Tools:

Angle grinders, cutoff saws, and basic milling machines can handle metal cutting too. These are more powerful and consistent than manual methods. Though not always CNC-controlled, some of these power tools can be retrofitted with basic controls. - Industrial CNC Machines:

This is where we hit the sweet spot. CNC mills, lathes, laser cutters, plasma cutters, and waterjet cutters are all forms of Metal Cutters. Each has its pros and cons. In a CNC mill, we might use end mills or ball-nose cutters. On a CNC lathe, we have turning tools and parting blades. Laser and plasma cutters focus beams of energy to melt or vaporize metal with extreme precision. Waterjets use high-pressure streams of water mixed with abrasive particles. All these methods count as Metal Cutter operations, just implemented differently.

Mechanical Metal Cutters (Traditional Tools in a CNC Context)

In CNC machining, the most common Metal Cutter is often a rotary tool like an end mill. End mills are used in milling machines. They come in various shapes—flat end, ball end, corner radius—and different flute counts. The right geometry depends on the feature you’re creating. For example, a two-flute end mill often works well in aluminum, allowing high chip clearance. A four-flute end mill might be better for steel, providing more cutting edges but requiring careful chip evacuation.

Common Mechanical Metal Cutters:

- End Mills:

Ideal for creating slots, profiles, pockets, and complex 3D shapes. They are staples in CNC milling. - Drill Bits:

While drilling is a separate operation, a drill bit is still a form of Metal Cutter. We use them to create holes before using other tools. - Reamers and Boring Tools:

Used to refine holes to very tight tolerances. - Turning Inserts:

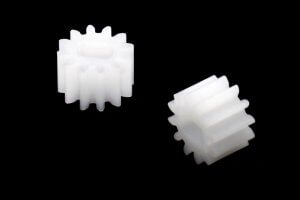

On a CNC lathe, inserts made of carbide or ceramic mount in tool holders. They shape the workpiece as it spins, cutting away material to form shafts, bores, or tapered surfaces. - Gear Cutters and Broaches:

More specialized cutters, used for producing gears or internal keyways.

High-Precision Cutting Equipment (Advanced Tools for CNC)

CNC isn’t limited to mechanical milling or turning. Laser, plasma, and waterjet are all Metal Cutters that can be CNC-guided:

- Laser Cutters:

A laser Metal Cutter uses a concentrated beam of light to cut through metal. It can produce intricate shapes with fine details and smooth edges. Laser cutters excel in thinner materials and complex contours, but might struggle with very thick or reflective metals. - Plasma Cutters:

Plasma Metal Cutters use ionized gas to melt metal at extremely high temperatures. They’re great for thicker sheets and can cut faster than many mechanical methods. The cut edges may require cleanup due to the heat-affected zone. Still, when integrated with CNC controls, plasma cutters produce consistent shapes at high speeds. - Waterjet Cutters:

A waterjet Metal Cutter uses high-pressure water mixed with abrasive particles. It can cut virtually any material, including hardened steel and titanium, without adding heat. This preserves material properties and prevents warping. Waterjets are versatile, though slower and more expensive to operate.

Specialty Tools: Thread Mills and Multifunctional Cutters

Thread milling is a process I find particularly interesting. Instead of using a tap to form threads by twisting into a hole, a thread mill (a type of Metal Cutter) moves in a helical pattern to cut threads. This approach offers flexibility—one thread mill can create different thread diameters—and reduces the risk of tool breakage. With CNC, programming a helical path is straightforward. Thread mills also produce better chip control, resulting in cleaner threads.

Multifunctional cutters attempt to combine various operations into a single tool, saving tool change time. Some end mills also chamfer edges or drill holes. While these are not always as optimal as dedicated tools, they increase efficiency in certain workflows.

Material Specificity and Tool Geometry

Each Metal Cutter’s design suits a range of materials. For example, a carbide end mill with TiAlN coating might excel in stainless steel due to its heat resistance. Another cutter with a polished flute and fewer flutes might be better for aluminum.

Why does geometry matter so much? Because cutting metal involves breaking chips off the material. The shape and sharpness of the cutter’s edge, the number of flutes, and their helix angle determine how chips form, how they’re evacuated, and how smoothly the tool engages the metal. In CNC machining, controlling these factors improves surface finish, prevents tool deflection, and extends tool life.

Consider the Machine and Fixturing

The best Metal Cutter in the world won’t help if your machine or setup is inadequate. A rigid CNC machine with good spindle bearings and stable fixturing allows you to use more aggressive Metal Cutter parameters. If your machine is older or less stable, you might favor cutters that produce lower cutting forces, like single-flute end mills for tough alloys.

Insert-Based vs. Solid Carbide Tools

Some CNC Metal Cutters, like turning tools or face mills, use indexable inserts. These inserts are small, replaceable cutting edges made from carbide or ceramic. Instead of sharpening the entire tool, you swap out an insert. This flexibility reduces downtime and costs over the long run.

Solid carbide end mills are one piece of hardened material. They’re more rigid and can produce excellent results, but once dull, you either regrind them or replace them entirely. In contrast, an indexable tool body can be reused many times with fresh inserts.

Why So Many Types?

At first, I wondered: why so many varieties of Metal Cutter tools? The answer is that modern manufacturing deals with diverse materials, shapes, and production volumes. The automotive industry might need rapid removal of steel for engine parts. Aerospace might require ultra-precise cutting of superalloys. Medical device makers might need mirror finishes on tiny components. Each scenario demands a unique combination of cutter geometry, material, and coating.

Cutting Parameters and Tool Selection

Even the best Metal Cutter performs poorly if the wrong parameters are used. You wouldn’t run a fine-tooth finishing end mill at a super high feed rate in hardened steel. Likewise, a cutter meant for steel might struggle in aluminum if it can’t clear chips effectively at higher RPMs. The synergy between the Metal Cutter type and cutting parameters is key.

Data Table 1: Common Metal Cutter Types vs. Applications

| Metal Cutter Type | Typical Application | Material Range | Notes |

|---|---|---|---|

| Two-Flute End Mill | Slotting, Profiling (Al) | Aluminum, Soft Steel | Great chip clearance |

| Four-Flute End Mill | General Milling (Fe) | Steel, Stainless Steel | Higher MRR, needs good chip evac |

| Ball-End Mill | 3D Contours (Precision) | Various | Smooth finishes on complex shapes |

| Thread Mill | Internal/External Threads | Steel, Inconel, Al | Flexible thread sizing, less breakage |

| Laser Cutter | Intricate Profiles (Thin) | Stainless, Mild Steel | High precision, low mechanical stress |

| Plasma Cutter | Thick Plate Cutting (Fast) | Carbon Steel, SS | High speed, may need post-processing |

| Waterjet Cutter | Heat-Sensitive Materials | Hardened Steel, Alloys | No heat-affected zone, versatile |

| Indexable Face Mill | Surface Facing (Large) | Steel, Cast Iron | Replaceable inserts, long tool life |

Data Table 2: Geometry and Coating Considerations

| Factor | Impact on Cutter Performance | Example |

|---|---|---|

| Flute Count | More flutes: higher feed, less chip space | 4-flute for steel, 2-flute for Al |

| Helix Angle | High helix: smooth cutting, better finish | 35°-45° helix end mills |

| Tool Material | Carbide: rigid, wear-resistant | Carbide end mill vs. HSS |

| Coating | TiN, TiAlN reduce wear, manage heat | TiAlN for stainless steel |

| Tool Diameter | Larger diameter: more rigidity | 1″ face mill vs. 1/4″ end mill |

| Cutter Length | Longer = more deflection | Short tool for tough materials |

| Nose Radius | Larger radius spreads cutting forces | Corner radius end mill for durability |

Balancing Performance, Cost, and Availability

When choosing a Metal Cutter, we often balance performance with cost. Advanced coated carbide tools cost more but may last longer and produce better parts. Simpler tools are cheaper but might wear out quickly, lowering overall productivity. In a CNC environment where precision and repeatability are valuable, investing in better cutters often pays off.

Specialized Metal Cutters for Special Shapes

Some industries use Metal Cutters specifically engineered for unique profiles. For instance, gear cutters form gear teeth profiles. Broaches cut internal shapes that would be hard to machine otherwise. These specialized tools may not be common in everyday CNC operations, but in niche manufacturing, they’re indispensable.

Considering Part Geometry and Batch Size

For high-volume production, using a Metal Cutter that removes material quickly and predictably is crucial. In aerospace or medical, small batches of high-precision parts might need cutters that provide perfect finishes, even if they cut slower. The choice of Metal Cutter also depends on whether you’re making many identical parts or constantly changing setups. Quick-change tooling and modular cutter systems help adapt to varying demands.

Evolution of Metal Cutters

As CNC technology advances, so do Metal Cutters. Improved carbide grades, advanced coatings, and geometric innovations continuously push the boundaries. Some cutters now feature chip-breaker patterns to manage chip shape. Others incorporate internal coolant channels to direct fluid right to the cutting edge.

Selecting Metal Cutters for CNC: A Practical Approach

When I choose a Metal Cutter for a CNC job, I consider:

- Material: Hardness, toughness, thermal conductivity.

- Operation Type: Milling, turning, threading, or cutting shapes with laser/plasma.

- Required Tolerances: Higher precision may need finer cutters or special geometries.

- Machine Capability: Spindle power, rigidity, and coolant availability.

- Cost and Availability: Balancing premium tools vs. standard cutters.

- Production Volume: High-volume runs might justify expensive but long-lasting tools.

By answering these questions, I narrow down the Metal Cutter options.

Integrating Tool Libraries into CAM Software

Modern CAM software allows me to define a tool library with details about each Metal Cutter. I can record diameter, flute count, material, coating, recommended feeds and speeds. This digital database streamlines the selection process. When I set up a new job, I pick a Metal Cutter from the library, and the software suggests cutting parameters based on past success.

Trends in Cutter Design

Lately, there’s been interest in tools designed for high-speed machining (HSM). These Metal Cutters have geometries that reduce cutting forces and allow higher RPMs, resulting in faster cycle times. Another trend involves variable helix end mills, where the flute helix angle changes along the length of the tool. This variation breaks up harmonics and reduces chatter.

Why Understanding Cutter Types Matters

If I don’t understand the difference between a low-flute end mill and a high-flute one, I might misuse the tool and struggle with poor finishes or premature wear. If I don’t know about laser or waterjet cutting, I might try to machine a complex shape on a mill that would be simpler done with a CNC laser. Understanding the landscape of Metal Cutters empowers me to pick tools that save time, improve quality, and reduce frustration.

Conclusion of Chapter 2

The world of the Metal Cutter is extensive, and each type has a role in CNC machining. From classic end mills to advanced laser systems, the variety reflects the complexity of modern manufacturing. By recognizing these differences, we set the stage for smarter tool selection, better results, and a more efficient CNC workflow.

Selecting the Right Metal Cutter Based on Material (≥1500 words)

When I first started working with different metals, I realized that not all Metal Cutters can handle every alloy equally well. Metal varies widely in hardness, ductility, thermal conductivity, and chemical reactivity. Choosing the best Metal Cutter means understanding the properties of the workpiece material, then selecting a tool that matches those characteristics.

Why Material Matters

Imagine cutting aluminum with a tool designed for hardened steel. The aluminum might stick to the cutter’s flute because the geometry and coating aren’t optimized for chip evacuation. Or try using a basic uncoated end mill in hardened steel: you’ll quickly dull the tool and get poor finishes. The relationship between material and Metal Cutter choice is fundamental. Proper pairing improves surface quality, extends tool life, and lowers costs.

Common Material Categories

Let’s break down some general categories and how they influence Metal Cutter selection:

- Aluminum and Soft Alloys:

Aluminum is relatively soft and highly machinable. It allows high cutting speeds, high feed rates, and it doesn’t require extremely robust cutters. However, aluminum is gummy and can stick to cutting edges if not cleared quickly.

For aluminum, I often choose a Metal Cutter with fewer flutes, maybe two or three, ensuring ample chip clearance. A polished flute surface helps prevent chip welding. Uncoated carbide often works fine, though DLC (Diamond-Like Carbon) coatings can further reduce friction. High helix end mills and sharp cutting edges excel here, providing a clean cut and bright finish. - Carbon Steel and Low-Alloy Steels:

These materials are harder than aluminum but still manageable. A standard carbide end mill with TiN coating can handle many steels. More flutes might be acceptable, as steels produce more manageable chips.

When cutting carbon steel, moderate speeds and feeds are common. A well-chosen Metal Cutter ensures good tool life. Using coolant helps with heat dissipation, maintaining edge sharpness. If I want better tool life, I might upgrade to a TiAlN coating for improved heat resistance. - Stainless Steel:

Stainless steels are tougher and more likely to work-harden. Using a Metal Cutter here requires careful approach. I might go with three or four flutes but ensure a rigid setup. A high-end coating like TiAlN or AlTiN helps handle the heat and reduce wear.

Slower speeds and higher feed per tooth can maintain a chip-thinning effect, preventing the cutter from rubbing and generating unnecessary heat. Coolant is crucial. The combination of a stable machine, rigid fixturing, and a well-chosen Metal Cutter makes all the difference. - Titanium Alloys:

Titanium is strong, lightweight, and has poor thermal conductivity. Heat stays at the cutting edge, wearing tools rapidly. For titanium, a robust carbide Metal Cutter with an advanced coating like AlTiN is almost mandatory. Use lower speeds, moderate feeds, and possibly high-pressure coolant to carry away heat. Sometimes a single-flute or two-flute cutter reduces cutting forces.

Chip evacuation is vital. If chips stay in the cutting zone, the Metal Cutter overheats and dulls quickly. Short, multiple passes and conservative depth of cut preserve tool life. - Inconel and Other Superalloys:

Superalloys resist deformation and retain strength at high temperatures. Machining them tests the limits of any Metal Cutter. I rely on top-quality carbide, possibly with a proprietary coating designed for nickel-based alloys. Feed rates and speeds must be even lower than titanium.

High-pressure coolant, stable tool holders, and incremental passes help. Sometimes using a roughing Metal Cutter first to remove bulk material, then a finishing cutter for the final pass, is a good strategy. - Hardened Steel and Tool Steels:

Hard steels require cutters that can handle significant wear. A Metal Cutter with a robust carbide substrate and wear-resistant coating is essential. Cutting parameters must be dialed back. Depth of cut is shallow, and finishing passes are light.

Here, the cost of the Metal Cutter matters less than its performance. Cheap tools die fast in hardened steel, while a premium cutter may save money long-term. - Exotic Materials (Copper, Brass, Bronze, Composites):

Copper and brass are relatively easy to machine, similar to aluminum, but watch out for chip formation. Composites or laminated metals might require specialty cutters that manage abrasive fibers. Adjusting parameters and choosing a Metal Cutter with geometry that reduces delamination or tearing is key.

Data Table 3: Material vs. Recommended Metal Cutter Characteristics

| Material | Hardness/Challenge | Recommended Cutter | Coating | Flute Count | Notes |

|---|---|---|---|---|---|

| Aluminum | Soft, Ductile | Carbide End Mill | Uncoated/DLC | 2-3 | High RPM, large chip space |

| Mild Steel | Medium Hardness | Carbide End Mill | TiN | 3-4 | Moderate speeds, coolant helps |

| Stainless Steel | Tough, Gummy | Carbide, Rigid Tool | TiAlN/AlTiN | 3-4 | Lower speed, higher feed, coolant critical |

| Titanium Alloys | Hard, Low Thermal Cond. | Carbide, Stiff Tool | AlTiN | 2-3 | High-pressure coolant, slow speed, moderate feed |

| Inconel/Superalloys | Very Hard, Heat-Resistant | High-end Carbide | Advanced (AlTiN+) | 2-3 | Very slow speed, short passes |

| Hardened Steel | Very Hard | Premium Carbide | AlTiN or similar | 2-4 | Shallow DOC, finishing passes |

| Brass/Copper | Soft, Malleable | Carbide or HSS | Uncoated/TiN | 2-3 | Similar to Al, but watch chip stickiness |

Adjusting Cutting Parameters to Material

After selecting a suitable Metal Cutter, I adjust cutting parameters to match the material. Softer metals allow higher spindle speeds and feeds. Harder metals require slower speeds to prevent rapid wear. Always refer to tool manufacturer recommendations, then tweak based on your machine’s capabilities and observed results.

Coatings and Their Importance

Why are coatings so vital? In challenging materials like stainless steel or Inconel, the cutting edge faces extreme friction and heat. A well-chosen coating reduces these factors, allowing the Metal Cutter to last longer. Without coatings, carbide tools might still work, but their lifespan shortens drastically, and surface finish can suffer.

Data Table 4: Coating Choices by Material

| Material | Common Coating Choice | Reason |

|---|---|---|

| Aluminum | Uncoated or DLC | Reduce buildup, high speeds |

| Steel | TiN or TiAlN | Wear resistance, moderate heat |

| Stainless Steel | TiAlN or AlTiN | Heat resistance, reduce wear |

| Titanium | AlTiN or Specialty | Extreme heat resistance |

| Inconel | AlTiN+ or Ceramic-based | Very high temp resilience |

| Hardened Steel | AlTiN or AlCrN | Enhanced wear resistance |

Considering Chip Evacuation and Tool Geometry

Different materials produce different types of chips. Aluminum creates long, stringy chips that must be cleared quickly. Stainless steel chips are tougher and can work-harden if not cut properly. For each material, choosing a Metal Cutter geometry that optimizes chip flow prevents chip recutting and tool rubbing.

High-flute-count tools can increase productivity in steels if you have robust chip evacuation strategies. But in gummy alloys, too many flutes can clog the cutter. Sometimes a tool with fewer flutes and larger flute valleys works better to clear chips.

Coolant and Material Compatibility

Coolant choice also depends on material. Water-based coolants are common, but in tough alloys or titanium, high-pressure coolant delivery at the cutting zone prevents heat buildup. For materials that are sensitive to heat (like titanium), coolant is crucial for preventing tool damage.

Trial Runs and Adjustments

Even with a perfect plan, I often do test cuts. Run a short pass, measure the surface finish, check the chips. If chips discolor (indicating heat), slow down or add more coolant. If the Metal Cutter shows wear too soon, try a better coating or reduce the cutting speed. Over time, these adjustments fine-tune your approach.

Modular Tool Systems and Material Flexibility

If you frequently switch between materials, modular tool systems help. By changing only the cutter head while keeping the same shank, you can quickly adapt to different materials without retooling the entire machine setup. This flexibility is valuable in job shops or prototyping environments.

Considering Economics

A premium Metal Cutter might seem expensive, but if you’re cutting tough materials that would destroy cheaper tools quickly, the expensive tool pays off. On the other hand, if you mostly cut aluminum in large batches, maybe a mid-range tool works well enough, balancing cost and performance.

Heat Management for Hard Materials

For titanium and superalloys, consider techniques like peck milling or trochoidal milling (a technique where the tool moves in a looping path to reduce cutting forces and heat). These methods keep the cutter from dwelling too long in one spot, distributing heat and wear more evenly.

Surface Finish Goals

If you need a mirror-like finish in aluminum, choose a sharp, high-helix cutter and run at high RPM with a finishing pass. For steel parts that need a good finish, try a stable cutter with TiN coating and adjust feed to achieve a smoother surface. If the material is hard, make multiple finishing passes at lower feed rates.

Real-World Example

I once had to machine stainless steel components with a tight tolerance and smooth finish requirement. Initially, I used a standard carbide end mill with no coating. The tool wore quickly, and the finish was dull. After switching to a TiAlN-coated end mill designed for stainless, I lowered the speed slightly and upped the feed slightly. The chips came off nicely, and the finish improved. Coolant flow was adjusted to directly hit the cutting edge. The result: increased tool life and consistent surface quality. This experience taught me that aligning material properties with the right Metal Cutter and parameters is essential.

Exotic Cases

If working with composites, the Metal Cutter might need a special geometry to cut through fibers without tearing them. In abrasive materials, coatings that resist wear become vital. Always research best practices for each material type, as some materials require truly specialized tooling.

Data-Driven Decisions

Keep records of what works: note spindle speeds, feeds, depth of cut, tool brand, coating type, and resulting tool life. Over time, you build a database of what Metal Cutter and parameters are best for each material. This data is gold when you face new projects.

Conclusion of Chapter 3

Selecting the right Metal Cutter based on the workpiece material is a cornerstone of successful CNC machining. Each metal demands its own balance of tool geometry, coating, coolant strategy, and cutting parameters. By understanding these material-specific nuances, you maximize tool life, achieve better finishes, and produce higher-quality parts. This knowledge forms the bedrock of efficient and effective machining operations.

Optimizing Efficiency and Precision in CNC Cutting

Achieving both efficiency and precision in CNC machining is a balancing act that hinges significantly on the choice and use of the right Metal Cutter. Over the years, I’ve experimented with various techniques and parameters to fine-tune my processes, and I’ve learned that optimizing these factors can lead to remarkable improvements in both speed and accuracy.

Programming Tips for Optimal Metal Cutting

One of the first steps in optimizing CNC cutting is setting the right programming parameters. The metal cutter’s performance is highly dependent on how well the CNC machine is programmed. Here are some key areas to focus on:

- Feed Rate and Spindle Speed:

The feed rate (how fast the cutter moves through the material) and spindle speed (how fast the cutter spins) must be carefully synchronized. For softer metals like aluminum, higher spindle speeds and feed rates are acceptable, allowing for quicker cuts. Conversely, harder materials like stainless steel or titanium require slower speeds and feeds to prevent excessive tool wear and ensure precision. - Cutting Depth and Passes:

Adjusting the depth of cut (DOC) is crucial. A deeper cut removes more material in a single pass, increasing efficiency but also placing more stress on the tool. For tougher materials, multiple shallow passes can enhance precision and extend tool life. This approach minimizes heat buildup and reduces the risk of tool breakage. - Helical Interpolation:

Utilizing helical interpolation for threading operations allows the metal cutter to follow a helical path, creating smooth and accurate threads. This technique is especially beneficial for internal threads, where traditional tapping might struggle.

The Importance of Cooling Systems

Effective cooling is paramount in CNC machining. Heat generated during cutting can lead to tool wear, poor surface finishes, and even workpiece deformation. Here’s how to optimize cooling:

- High-Pressure Coolant:

In my experience, high-pressure coolant systems significantly improve chip evacuation and heat dissipation. This is particularly important when working with high-strength alloys like Inconel or titanium. Directing coolant precisely at the cutting edge ensures that heat is quickly removed, maintaining tool sharpness and preventing thermal damage to the workpiece. - Coolant Types:

Choosing the right coolant type based on the material is essential. For example, water-soluble coolants work well with aluminum, providing excellent lubrication and cooling. For stainless steels and other harder materials, oil-based coolants offer better lubrication and reduce friction, enhancing tool life.

Preventing Vibration and Tool Deformation

Vibration and tool deflection can compromise both the efficiency and precision of CNC cutting. To mitigate these issues, consider the following strategies:

- Stable Fixturing:

Ensuring that the workpiece is securely fixtured minimizes movement during cutting. Inadequate fixturing can lead to vibrations, which not only affect the surface finish but also increase the likelihood of tool wear or breakage. - Tool Geometry:

Selecting Metal Cutters with appropriate geometry can reduce the chances of vibration. For instance, using a single-flute cutter in harder materials can lower the cutting forces compared to multi-flute cutters, resulting in smoother operations. - Machine Maintenance:

Regular maintenance of the CNC machine ensures that all components are functioning correctly. Loose bearings, worn spindles, or misaligned axes can introduce unwanted vibrations. Keeping the machine in optimal condition is a simple yet effective way to enhance cutting performance.

Data Table 1: Optimizing Cutting Parameters for Different Materials

| Material | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (DOC) | Recommended Passes | Coolant Type | Notes |

|---|---|---|---|---|---|---|

| Aluminum | 3000 – 4000 | 15 – 25 | 0.020″ – 0.040″ | 1 – 2 | Water-Soluble | High speed, minimal chip control needed |

| Mild Steel | 1000 – 1500 | 5 – 10 | 0.010″ – 0.020″ | 2 – 3 | Oil-Based | Moderate speed, ensure good lubrication |

| Stainless Steel | 800 – 1200 | 3 – 7 | 0.005″ – 0.015″ | 2 – 4 | Oil-Based | Slower speeds, high-pressure coolant needed |

| Titanium Alloys | 600 – 1000 | 2 – 4 | 0.005″ – 0.010″ | 3 – 5 | High-Pressure Oil | Extremely slow speeds, multiple passes |

| Inconel 718 | 500 – 800 | 2 – 5 | 0.003″ – 0.006″ | 3 – 6 | High-Pressure Oil | Very slow speeds, short incremental passes |

| Brass/Copper | 2000 – 3000 | 10 – 20 | 0.010″ – 0.020″ | 1 – 2 | Water-Soluble | High productivity, easy chip evacuation |

Advanced CNC Programming Techniques

Beyond basic parameter adjustments, advanced programming techniques can further optimize Metal Cutter performance:

- Trochoidal Milling:

This technique involves a circular toolpath that allows the cutter to make multiple small passes rather than a single large one. It reduces the load on the tool, minimizes heat generation, and improves chip evacuation. Trochoidal milling is especially effective in hard materials where traditional milling might lead to rapid tool wear. - Adaptive Toolpaths:

Adaptive toolpaths adjust cutting parameters in real-time based on feedback from the machine. This ensures that the Metal Cutter operates within optimal conditions, maintaining precision and efficiency even as material properties or machine conditions change.

Tool Radius Compensation and Scaling

Sometimes, threads or cuts might not come out perfectly sized on the first attempt. Metal Cutters allow for adjustments through radius compensation or scaling factors:

- Radius Compensation:

By slightly adjusting the toolpath radius, I can fine-tune the thread diameter or the overall fit of the cut. This is particularly useful for achieving tight tolerances without changing the cutter. - Scaling Factors:

Scaling involves slightly enlarging or reducing the entire toolpath. This method helps in correcting minor discrepancies in thread size or shape, ensuring that the final product meets the desired specifications.

Data Table 2: Advanced Techniques for Metal Cutting Optimization

| Technique | Purpose | Application | Benefits |

|---|---|---|---|

| Trochoidal Milling | Reduce tool load, improve chip flow | Hard materials (stainless steel) | Extends tool life, minimizes heat |

| Adaptive Toolpaths | Real-time parameter adjustment | Dynamic machining environments | Maintains precision, adapts to changes |

| Tool Radius Compensation | Fine-tune thread and cut sizes | Thread milling, precise cuts | Achieves tight tolerances without tool change |

| Scaling Factors | Adjust overall toolpath dimensions | Prototyping, tolerance correction | Ensures final dimensions meet specifications |

| Peck Milling | Improve chip evacuation | Deep holes, tough materials | Prevents chip clogging, reduces heat |

| Variable Helix End Mills | Reduce vibrations, enhance finish | High-speed machining | Smooth surface finishes, increased stability |

Balancing Productivity and Tool Life

In CNC machining, productivity and tool life often compete. Pushing Metal Cutters to their limits can yield faster production times but may also shorten tool lifespan. Here’s how to balance these factors:

- Assess Production Needs:

High-volume production might prioritize speed, even if it means slightly reduced tool life. Conversely, low-volume or high-precision jobs might value tool longevity and accuracy over sheer speed. - Tool Selection:

Investing in higher-quality Metal Cutters with advanced coatings can provide better performance and longer life, even at higher speeds. This upfront cost can pay off by reducing downtime and the need for frequent tool changes. - Regular Monitoring:

Keeping an eye on tool wear and performance ensures that you can make timely adjustments. Monitoring software or manual inspections help in identifying when a tool is nearing the end of its useful life, preventing unexpected failures. - Parameter Optimization:

Fine-tuning cutting parameters to find the sweet spot between speed and wear extends tool life without sacrificing too much productivity. It’s an ongoing process that benefits from continuous experimentation and data collection.

Case Study: Optimizing Parameters for Stainless Steel Cutting

In one project, I was tasked with producing precision stainless steel components with tight tolerances. Initially, I used a standard four-flute carbide end mill with a TiN coating, running at moderate speeds and feeds. However, the tool wear was faster than expected, and the surface finish wasn’t as smooth as required.

After analyzing the parameters and consulting with the tool manufacturer, I switched to a single-flute thread mill with a TiAlN coating. I also reduced the spindle speed slightly and increased the feed rate incrementally while maintaining a shallow depth of cut. Additionally, I upgraded the coolant system to deliver high-pressure streams directly to the cutting edge.

The results were impressive: tool life doubled, and the surface finish improved significantly. The single-flute design allowed better chip evacuation, preventing recutting and reducing heat buildup. This case reinforced the importance of matching the Metal Cutter type and coating to the specific material and application.

Implementing Advanced Tool Holders and Toolpath Strategies

Modern CNC machines offer advanced tool holders and toolpath strategies that can further enhance Metal Cutter performance:

- Advanced Tool Holders:

Tool holders with better rigidity and vibration dampening capabilities can reduce chatter and improve surface finish. Investing in high-quality tool holders ensures that the Metal Cutter remains stable during cutting operations. - Optimized Toolpaths:

Strategies like ramping or climbing cuts can minimize tool deflection and enhance chip control. These techniques involve gradually engaging the cutter with the material, reducing sudden forces that can lead to vibration or tool wear.

Conclusion of Chapter 4

Optimizing efficiency and precision in CNC metal cutting is a multifaceted endeavor that requires a deep understanding of both the Metal Cutter and the machining process. By carefully selecting cutting parameters, utilizing advanced programming techniques, ensuring effective cooling, and maintaining tool and machine integrity, significant improvements in both productivity and accuracy can be achieved.

The journey to mastering Metal Cutters is ongoing, with continuous learning and adaptation playing key roles. Whether you’re refining existing processes or tackling new materials, the principles of optimization remain the same: balance speed with precision, protect your tools with proper cooling, and always seek ways to enhance chip evacuation and reduce vibrations. These strategies not only improve your machining outcomes but also extend the life of your Metal Cutters, ultimately contributing to a more efficient and profitable operation.

Common Problems and Solutions

Even with the best Metal Cutter and optimized parameters, challenges can still arise in CNC machining. Over time, I’ve encountered various issues that tested my troubleshooting skills and deepened my understanding of Metal Cutter dynamics. Addressing these common problems effectively ensures smooth operations and consistent quality.

Problem 1: Tool Breakage and Premature Wear

Nothing disrupts a CNC operation faster than a broken Metal Cutter. Tool breakage not only halts production but also can damage the workpiece and the machine. Premature wear, where the tool loses sharpness quicker than expected, also poses significant issues.

Causes:

- Excessive Cutting Forces: Applying too much depth of cut or feed rate can overload the tool.

- Inadequate Cooling: Insufficient coolant leads to overheating, weakening the tool material.

- Improper Tool Selection: Using a Metal Cutter not suited for the material or operation increases stress.

- Machine Vibrations: Lack of rigidity or loose fixturing can cause erratic cutting forces.

Solutions:

- Adjust Cutting Parameters:

Lowering the feed rate or spindle speed reduces the load on the Metal Cutter. For example, in stainless steel, reducing the depth of cut from 0.020″ to 0.010″ can significantly decrease stress on the tool. - Enhance Cooling Systems:

Upgrading to high-pressure coolant ensures that heat is efficiently removed from the cutting zone. Directing coolant specifically at the tool’s contact point can prolong tool life. - Select the Right Metal Cutter:

Ensure that the Metal Cutter’s material, geometry, and coating match the cutting requirements. For harder materials like Inconel, using a single-flute thread mill with an AlTiN coating is advisable. - Improve Machine Stability:

Tightening fixtures and ensuring the CNC machine is well-maintained reduces vibrations. Using tool holders with better rigidity can also help prevent tool deflection and breakage.

Case Study: Preventing Tool Breakage in Titanium Machining

In a recent project, I was machining titanium alloy parts with tight tolerances. Initially, I used a multi-flute end mill, but experienced frequent tool breakages. After switching to a single-flute thread mill with an AlTiN coating and reducing the spindle speed, tool life improved dramatically. Additionally, I upgraded the coolant system to deliver high-pressure streams directly to the cutter, further preventing overheating and tool failure.

Problem 2: Poor Thread Finish or Surface Quality

Achieving a smooth, consistent thread finish is crucial, especially in applications where threads must fit precisely or seal effectively. Poor surface quality can lead to functional failures and increased wear on mating parts.

Causes:

- Chatter and Vibrations: These cause uneven cutting and tool deflection, leading to rough threads.

- Dull or Improperly Coated Tools: A dull Metal Cutter can rub rather than cut, deteriorating surface quality.

- Incorrect Cutting Parameters: Too high a feed rate or spindle speed can compromise thread accuracy.

- Inadequate Chip Evacuation: Accumulated chips can interfere with the cutting process, resulting in uneven surfaces.

Solutions:

- Stabilize the Cutting Environment:

Ensure that the CNC machine is stable and free from vibrations. Using a single-flute cutter can help minimize chatter, leading to smoother thread finishes. - Maintain Sharp Tools:

Regularly inspect and replace dull Metal Cutters. A sharp tool cuts cleanly, improving surface finish. Using a Metal Cutter with a suitable coating also reduces friction and enhances surface quality. - Optimize Cutting Parameters:

Fine-tuning spindle speeds and feed rates can enhance thread precision. For instance, lowering the feed rate slightly while maintaining spindle speed can lead to finer threads. - Improve Chip Evacuation:

Ensuring efficient chip removal prevents interference with the cutting process. High-pressure coolant and appropriate tool geometry aid in effective chip evacuation.

Case Study: Enhancing Thread Finish in Aluminum

While machining aluminum threads, I noticed that the initial threads were rough and uneven. By switching to a single-flute thread mill and increasing the spindle speed, I achieved a smoother finish. Additionally, adjusting the feed rate to a slightly lower value allowed for better control and a more consistent thread profile. The result was a significant improvement in surface quality without sacrificing cutting speed.

Problem 3: Incorrect Thread Size or Fit

Accurate thread sizing is essential for ensuring that components fit together correctly. An incorrect thread size can lead to functional issues, such as leaks in sealed applications or mechanical failures.

Causes:

- Toolpath Errors: Inaccurate programming can result in threads that are too tight or too loose.

- Tool Wear: A worn Metal Cutter alters the thread dimensions, leading to incorrect sizing.

- Material Springback: Some materials may spring back after cutting, affecting thread dimensions.

Solutions:

- Adjust Toolpath Offsets:

Minor adjustments to the toolpath radius can correct thread sizes. This flexibility allows for precise tuning without changing the Metal Cutter. - Double-Check Tool Dimensions:

Verify the Metal Cutter’s dimensions before starting. Using a tool presetter or precise measuring instruments ensures that the cutter size matches the programmed specifications. - Run Finishing Passes:

Performing additional finishing passes with adjusted parameters can refine thread dimensions. This is particularly useful if the initial cut was slightly off. - Account for Material Behavior:

Understanding how different materials behave during machining helps in anticipating and compensating for any springback or deformation.

Data Table 3: Adjusting Toolpath for Accurate Thread Sizing

| Adjustment Type | Purpose | Method | Impact |

|---|---|---|---|

| Radius Offset | Correct thread diameter | Modify toolpath radius in CAM software | Achieves desired thread fit without tool change |

| Tool Measurement | Ensure cutter matches specifications | Use tool presetter or micrometer | Prevents size discrepancies |

| Finishing Passes | Refine thread dimensions | Program additional light passes | Enhances accuracy and surface finish |

| Material Compensation | Account for springback or deformation | Adjust programming based on material behavior | Ensures thread remains within tolerance |

| Depth of Cut Adjustment | Fine-tune thread depth | Slightly modify axial movement | Maintains thread profile integrity |

| Feed Rate Modification | Control thread tightness | Increase or decrease feed rate | Achieves optimal thread fit |

Case Study: Correcting Thread Fit in Carbon Steel

I was machining M10 threads in carbon steel for a critical application. The initial threads were slightly undersized, causing fit issues. By adjusting the toolpath radius offset in the CAM software, I was able to enlarge the threads without changing the Metal Cutter. Additionally, running a finishing pass with a shallow depth of cut refined the thread profile, ensuring it met the required specifications. This approach saved time and resources by avoiding tool changes and reducing material waste.

Problem 4: Chatter and Vibration

Chatter, the unwanted vibration during cutting, can severely impact both tool life and surface finish. It often results in poor-quality threads and can lead to accelerated tool wear or breakage.

Causes:

- Machine Rigidity: An unsteady machine setup can amplify vibrations.

- Tool Overhang: Excessive tool length increases the likelihood of chatter.

- Improper Tool Selection: A Metal Cutter not suited for the operation can introduce instability.

- Cutting Parameters: Incorrect speeds and feeds can exacerbate vibrations.

Solutions:

- Reduce Depth of Cut and Feed Rate:

Lighter cutting loads minimize vibrations. Reducing the depth of cut from 0.020″ to 0.010″ and slightly lowering the feed rate can stabilize the cutting process. - Adjust Spindle Speed:

Sometimes, changing the spindle speed slightly can move the cutting frequency away from the machine’s natural resonance, reducing chatter. - Use a Stiffer Tool Setup:

Shortening the tool overhang or using a more rigid tool holder can significantly reduce vibrations. A balanced, robust tool setup is less prone to deflection. - Select Appropriate Tool Geometry:

Opt for Metal Cutters with geometry that dampens vibrations. Single-flute cutters, for example, engage less cutting force per revolution, which can help in minimizing chatter.

Data Table 4: Strategies to Mitigate Chatter in CNC Cutting

| Strategy | Implementation | Benefits |

|---|---|---|

| Reduce Depth of Cut | Lower DOC from 0.020″ to 0.010″ | Decreases cutting forces, stabilizes tool |

| Adjust Spindle Speed | Change RPM by ±10% | Moves frequency away from machine resonance |

| Shorten Tool Overhang | Use shorter tool length | Enhances tool rigidity, reduces deflection |

| Use Single-Flute Cutters | Switch to single-flute thread mills | Reduces cutting force per revolution, minimizes vibrations |

| Enhance Machine Rigidity | Tighten fixtures, ensure machine stability | Reduces external sources of vibration |

| Optimize Tool Holder | Use rigid, vibration-dampening holders | Maintains stable tool alignment |

Case Study: Eliminating Chatter in Stainless Steel Machining

While machining stainless steel threads, I encountered significant chatter, resulting in uneven thread surfaces. After evaluating the setup, I noticed that the tool overhang was too long, contributing to instability. By shortening the tool length and switching to a single-flute thread mill, the chatter was eliminated. Additionally, lowering the spindle speed and slightly reducing the feed rate helped stabilize the cutting process. The result was smooth, consistent threads and extended tool life.

Problem 5: Chip Clogging and Poor Evacuation

Efficient chip evacuation is crucial for maintaining cutting quality and tool performance. Chip clogging can lead to tool rubbing, overheating, and ultimately, poor thread quality.

Causes:

- Metal Cutter Design: Multi-flute cutters might not provide enough space for chips to escape in certain materials.

- Cutting Parameters: High feed rates can produce excessive chips that are difficult to evacuate.

- Coolant Application: Insufficient or improperly directed coolant fails to clear chips effectively.

Solutions:

- Use Metal Cutters with Fewer Flutes:

Single-flute or two-flute cutters provide more space for chips to escape, reducing the likelihood of clogging. This is especially beneficial when machining materials that produce sticky or stringy chips, like stainless steel. - Optimize Coolant Flow:

Ensure that coolant is directed precisely at the cutting edge to flush chips away from the toolpath. High-pressure coolant systems can significantly enhance chip evacuation, especially in deep or complex cuts. - Implement Pecking or Interrupted Cuts:

In deep-thread applications, incorporating pecking strategies—where the cutter intermittently retracts to clear chips—can prevent accumulation and improve overall cutting performance. - Choose Appropriate Tool Geometry:

Metal Cutters with optimized chip-breaking features help in managing chip flow. Tools with chip grooves or altered helix angles can facilitate smoother chip evacuation.

Data Table 5: Metal Cutter Designs and Chip Evacuation Efficiency

| Metal Cutter Design | Suitable Materials | Chip Type | Evacuation Efficiency | Notes |

|---|---|---|---|---|

| Single-Flute Cutter | Stainless steel, titanium | Stringy, sticky | High | Better chip clearance, less clogging |

| Two-Flute Cutter | Aluminum, brass | Thin, short chips | Moderate | Good balance between cutting and evacuation |

| Multi-Flute Cutter | Mild steel, carbon steel | Short, hard chips | Low | Higher productivity but poor chip evacuation |

| Chip-Breaking Geometry | Various | Varies | Enhanced | Reduces chip size, prevents recutting |

| Helix Angle Variation | Hard materials | Controlled shape | Improved | Optimizes chip flow based on material |

| Insert-Based Cutters | Diverse materials | Consistent | Variable | Depends on insert design and replacement frequency |

Case Study: Improving Chip Evacuation in Carbon Steel

During a batch production run of carbon steel threaded parts, I noticed that chips were piling up around the cutting area, leading to poor thread finishes and accelerated tool wear. To address this, I switched from a four-flute to a two-flute thread mill. The reduced number of flutes allowed for better chip evacuation. Additionally, I adjusted the coolant nozzles to deliver high-pressure streams directly to the cutting zone, effectively flushing away the chips. These changes resulted in cleaner threads and extended tool life, proving the importance of proper Metal Cutter selection and coolant management.

Problem 6: Inconsistent Tool Life

Consistency in tool life is vital for maintaining production schedules and controlling costs. Variations in tool wear can disrupt workflow and increase expenses due to frequent tool replacements.

Causes:

- Variability in Cutting Parameters: Inconsistent speeds, feeds, or depths of cut can lead to uneven tool wear.

- Material Inconsistencies: Variations in workpiece material properties can affect tool performance.

- Machine Stability: Fluctuations in machine performance, such as spindle runout or temperature variations, can impact tool longevity.

- Tool Quality: Using lower-quality Metal Cutters can result in unpredictable wear patterns and shorter tool life.

Solutions:

- Maintain Consistent Cutting Parameters:

Standardizing speeds, feeds, and depths of cut ensures uniform tool wear. Implementing standardized procedures and using reliable CNC programs help maintain consistency. - Monitor Material Quality:

Ensure that the materials being machined meet the required specifications. Variations in hardness or composition can affect tool performance. Using consistent batches of material reduces unpredictability. - Regular Machine Maintenance:

Keeping the CNC machine in optimal condition minimizes fluctuations that can affect tool wear. Regularly inspect and maintain spindle bearings, tool holders, and alignment to ensure stable operations. - Invest in High-Quality Metal Cutters:

Higher-quality cutters, though more expensive upfront, offer better consistency and longer tool life. They are designed to withstand varying cutting conditions and provide reliable performance. - Use Tool Presetters and Gauges:

Regularly measuring and presetting tool lengths and diameters ensures that the Metal Cutters are within specifications. This practice helps in maintaining consistent cutting conditions. - Implement Predictive Maintenance:

Utilizing sensors and monitoring software to track tool wear and machine performance can predict when tools need replacement, preventing unexpected failures and maintaining production flow.

Case Study: Achieving Consistent Tool Life in Mild Steel Production

In a production line focused on mild steel components, I faced issues with inconsistent tool life, leading to frequent tool changes and downtime. After analyzing the process, I identified that minor variations in feed rates were causing uneven wear. By standardizing the feed rate and implementing a rigid tool holding system, tool wear became more predictable and uniform. Additionally, switching to a higher-quality Metal Cutter with a TiAlN coating extended tool life by 30%. These adjustments not only stabilized tool performance but also reduced operational costs by minimizing tool replacements and downtime.

Preventive Measures for Long-Term Success

While troubleshooting is essential, preventive measures can significantly reduce the occurrence of common CNC cutting problems. Here are some best practices to implement:

- Proper Tool Selection:

Always choose the right Metal Cutter for the material and operation. This foundational step prevents many issues related to tool wear, breakage, and poor finishes. - Regular Tool Maintenance:

Inspect and maintain Metal Cutters regularly. Replace dull or damaged tools promptly to maintain cutting performance and surface quality. - Optimize Cutting Environment:

Ensure that the CNC machine environment is conducive to stable cutting operations. This includes proper ventilation, consistent coolant supply, and maintaining optimal machine settings. - Continuous Learning and Adaptation:

Stay updated with the latest advancements in Metal Cutter technologies and CNC programming techniques. Adapting to new tools and methods can lead to improved machining efficiency and quality. - Documentation and Standardization:

Keep detailed records of cutting parameters, tool usage, and machining outcomes. Standardizing processes based on this data ensures repeatable results and helps in quickly identifying and addressing issues.

Data Table 6: Predictive Maintenance Indicators for Metal Cutters

| Indicator | Description | Action Required |

|---|---|---|

| Tool Wear Measurements | Regularly measure cutter edge wear | Replace or sharpen tool as needed |

| Vibration Levels | Monitor for excessive machine vibrations | Check machine stability and tool setup |

| Surface Finish Quality | Inspect thread or cut surface for defects | Adjust parameters or tool selection |

| Cutting Force Trends | Track force applied during cutting | Optimize feed rates or tool geometry |

| Temperature Readings | Monitor cutting zone temperatures | Enhance cooling or reduce cutting speed |

| Chip Formation Patterns | Analyze chip size and shape | Modify toolpath or cutter type |

Case Study: Implementing Predictive Maintenance in High-Volume Production

In a high-volume production setting, consistent tool life was crucial. By implementing a predictive maintenance program, I tracked indicators like tool wear measurements and vibration levels. Using sensors, I monitored tool condition in real-time, allowing for proactive tool changes before wear affected quality. This approach minimized unexpected tool breakages and maintained a steady production flow. The predictive maintenance strategy not only improved tool longevity but also enhanced overall machining reliability and efficiency.

Conclusion of Chapter 5

Navigating the challenges of CNC metal cutting requires a blend of knowledge, experience, and proactive problem-solving. Common issues like tool breakage, poor surface finish, incorrect thread sizing, chatter, chip clogging, and inconsistent tool life can significantly impact machining operations. However, by understanding the root causes and implementing targeted solutions, these problems can be effectively managed.

The key lies in selecting the right Metal Cutter, optimizing cutting parameters, ensuring effective cooling, maintaining machine stability, and adopting preventive maintenance practices. Real-world case studies demonstrate that thoughtful adjustments and investments in quality tools lead to improved machining outcomes and operational efficiency.

As CNC technology continues to evolve, staying informed about new Metal Cutter designs, coatings, and machining techniques will further enhance your ability to produce high-precision, high-quality metal components. Embracing these strategies not only solves immediate problems but also sets the foundation for sustained success in CNC machining.

Latest Trends in Metal Cutting Technology

Staying ahead in CNC machining means keeping up with the latest advancements in Metal Cutter technology. The landscape is continually evolving, driven by innovations in materials, coatings, machine capabilities, and software integrations. Embracing these trends not only enhances efficiency and precision but also opens new possibilities for complex and high-performance machining tasks.

Advanced Tool Materials and Coatings

Metal Cutter technology has seen significant advancements in both materials and coatings, enabling better performance and longer tool life.

- Nanocoatings and Diamond-Like Carbon (DLC):

These coatings reduce friction and enhance heat resistance. Nanocoatings provide a smoother surface, which minimizes chip adhesion and extends tool life, especially in tough materials like stainless steel and titanium alloys. - Ceramic and Cermet Tools:

Ceramics offer exceptional hardness and wear resistance, making them ideal for high-speed machining of hardened steels and superalloys. Cermets, a composite of ceramic and metallic materials, combine the hardness of ceramics with the toughness of metals, providing a balanced performance for various applications.

High-Pressure Coolant and Cryogenic Machining

Effective cooling is critical in CNC machining, and new cooling technologies are revolutionizing Metal Cutter performance.

- High-Pressure Coolant Systems:

These systems deliver coolant directly to the cutting edge at high pressures, significantly improving chip evacuation and heat dissipation. High-pressure coolant is especially beneficial when machining difficult materials like Inconel and titanium, where heat management is crucial. - Cryogenic Machining:

Using liquid nitrogen or other cryogenic fluids, this method drastically reduces the temperature at the cutting zone. Cryogenic machining minimizes thermal stress on both the workpiece and the Metal Cutter, enhancing tool life and improving surface finish. Although still emerging, cryogenic techniques show great promise for high-performance machining applications.

Additive Manufacturing and Hybrid Machines

The integration of additive manufacturing (AM) with traditional CNC machining is creating hybrid machines that offer unparalleled flexibility and efficiency.

- Hybrid Machining Systems:

These machines combine 3D printing with CNC cutting, allowing for the creation of near-net shape parts that are then finished with precise Metal Cutter operations. This approach reduces material waste, shortens lead times, and enables the production of complex geometries that are difficult to achieve with subtractive methods alone. - Customized Toolpaths for AM Parts:

As AM technology evolves, so does the need for specialized Metal Cutter toolpaths. Custom toolpath strategies are being developed to accommodate the unique surface finishes and internal structures of 3D-printed parts, ensuring seamless integration between additive and subtractive processes.

Smart Tool Holders and Sensor Integration

The rise of Industry 4.0 has introduced smart technologies into CNC machining, enhancing the capabilities of Metal Cutters through real-time monitoring and adaptive control.

- Smart Tool Holders:

These holders are equipped with sensors that monitor parameters like vibration, temperature, and cutting forces in real-time. By analyzing this data, the CNC machine can adjust cutting parameters on the fly, optimizing performance and preventing tool wear or breakage. - Real-Time Monitoring Systems:

Integrated sensor systems provide continuous feedback on the cutting process, allowing for immediate adjustments to maintain optimal conditions. This proactive approach reduces downtime, extends tool life, and ensures consistent machining quality.

CAM Software Innovations and Automation

Computer-Aided Manufacturing (CAM) software is becoming increasingly sophisticated, leveraging artificial intelligence (AI) and machine learning to enhance Metal Cutter programming and optimization.

- AI-Driven Parameter Optimization:

Modern CAM systems use AI to analyze historical machining data and recommend optimal cutting parameters for new jobs. This reduces the trial-and-error phase, speeding up the setup process and improving initial outcomes. - Automated Toolpath Generation:

Advanced algorithms in CAM software can automatically generate efficient toolpaths that minimize tool wear and machining time. Features like adaptive toolpath strategies and dynamic parameter adjustments ensure that the Metal Cutter operates at peak performance throughout the machining process.

Sustainable Manufacturing and Tool Life Management

Sustainability is becoming a key focus in manufacturing, influencing Metal Cutter design and usage.

- Eco-Friendly Coatings:

New coatings are being developed to reduce environmental impact by minimizing the use of hazardous materials and improving tool recyclability. These coatings not only enhance performance but also align with green manufacturing practices. - Tool Life Management Systems:

Implementing systems to track and manage tool life ensures that Metal Cutters are used efficiently and replaced only when necessary. This reduces waste, lowers costs, and supports sustainable production practices.

Data Table 6: Emerging Metal Cutting Technologies and Their Benefits

| Technology | Description | Benefits | Applications |

|---|---|---|---|

| Nanocoatings | Ultra-thin, smooth surface coatings | Reduced friction, longer tool life | Stainless steel, titanium alloys |

| Diamond-Like Carbon (DLC) | Carbon-based coatings with diamond properties | Enhanced wear resistance, low friction | Precision machining, high-speed cuts |

| Ceramic Tools | High-hardness ceramic Metal Cutters | Exceptional wear resistance, high temp tolerance | Hardened steel, superalloys |

| High-Pressure Coolant | Direct, high-pressure coolant delivery | Improved chip evacuation, better cooling | Inconel, titanium, thick materials |

| Cryogenic Machining | Use of cryogenic fluids to reduce cutting temp | Minimizes thermal stress, extends tool life | High-performance alloys |

| Hybrid Machining Systems | Combination of additive and subtractive processes | Reduced material waste, complex geometry production | Aerospace, medical devices |

| Smart Tool Holders | Tool holders with integrated sensors | Real-time monitoring, adaptive control | All CNC machining applications |

| AI-Driven CAM Optimization | AI algorithms for parameter selection | Faster setup, optimized cutting parameters | Diverse CNC operations |

| Automated Toolpath Generation | AI-based toolpath creation | Efficient machining, reduced tool wear | Complex and high-precision parts |

| Eco-Friendly Coatings | Sustainable, low-impact tool coatings | Aligns with green practices, performance enhancement | All environmentally conscious machining |

Conclusion of Chapter 6

The latest trends in Metal Cutter technology are driving significant improvements in CNC machining efficiency, precision, and sustainability. By adopting advanced materials and coatings, leveraging high-pressure and cryogenic cooling systems, integrating additive manufacturing with traditional processes, utilizing smart tool holders, and embracing AI-driven CAM innovations, machinists can achieve unparalleled performance and adaptability. Staying informed about these trends and incorporating them into your machining practices will ensure that you remain competitive and capable of meeting the evolving demands of modern manufacturing.

User Cases and Practical Insights

Real-world applications and user experiences provide invaluable insights into the effective use of Metal Cutters in CNC machining. Through practical examples, we can understand how theory translates into practice, highlighting challenges and successful strategies for optimizing Metal Cutter performance.

Case Study 1: Efficient Cutting of Stainless Steel on CNC Lathes

In a recent project, I was tasked with producing stainless steel shafts for industrial machinery. Stainless steel’s toughness and tendency to work-harden presented significant challenges. Initially, the surface finish was rough, and tool wear was faster than anticipated.

Approach:

- Tool Selection:

I chose a high-quality single-flute thread mill with a TiAlN coating, specifically designed for stainless steel. - Cutting Parameters:

I reduced the spindle speed to 1200 RPM and adjusted the feed rate to 6 IPM, ensuring a manageable chip load. - Cooling Optimization:

Implemented a high-pressure coolant system to effectively flush away chips and dissipate heat.

Results:

- Improved Surface Finish:

The threads were smooth and consistent, meeting the stringent quality requirements. - Extended Tool Life:

The TiAlN coating and optimized parameters doubled the tool life, reducing the frequency of tool changes and increasing overall productivity. - Reduced Downtime:

With fewer tool breaks and changes, the production flow remained steady, enhancing efficiency.

Insights:

Choosing the right Metal Cutter and fine-tuning the cutting parameters are crucial when working with tough materials like stainless steel. High-quality coatings and effective cooling solutions significantly impact both tool longevity and machining quality.

Case Study 2: Using Multifunctional Metal Cutters for Complex Parts

In another project, I needed to machine complex aerospace components with intricate profiles and tight tolerances. Traditional Metal Cutters struggled with maintaining precision and surface finish across the varied geometries.

Approach:

- Tool Selection:

I opted for a multifunctional Metal Cutter that combined milling and turning capabilities, allowing for more versatile toolpaths. - Advanced Toolpath Programming:

Utilized adaptive toolpath strategies in the CAM software to dynamically adjust cutting parameters based on real-time feedback. - Precision Setup:

Ensured that the CNC machine was rigidly fixtured and that tool holders were stable to prevent vibrations.

Results:

- Enhanced Precision:

The multifunctional cutter maintained high precision across all complex geometries, meeting aerospace industry standards. - Improved Efficiency:

Reduced the number of tool changes required, streamlining the machining process and saving valuable production time. - Consistent Quality:

Achieved uniform surface finishes and dimensional accuracy, critical for aerospace applications.

Insights:

Multifunctional Metal Cutters can significantly enhance machining capabilities for complex parts. Combining different cutting functions in a single toolpath reduces tool changes, improves efficiency, and ensures consistent quality across intricate designs.

Case Study 3: Tackling Heat Issues in Titanium Alloy Cutting

Titanium alloys are known for their strength and lightweight properties, making them ideal for aerospace and medical applications. However, their poor thermal conductivity poses significant challenges in CNC machining, often leading to heat buildup and rapid tool wear.

Approach:

- Tool Selection:

Selected a single-flute thread mill with an AlTiN coating, specifically designed for high-temperature applications. - Cutting Parameters:

Implemented very low spindle speeds (800 RPM) and minimal feed rates (3 IPM) to reduce heat generation. - Cooling Enhancements:

Upgraded to a high-pressure coolant system to deliver coolant directly to the cutting edge, effectively managing the heat generated during machining. - Process Adjustments:

Adopted a multi-pass approach, removing small amounts of material in each pass to prevent excessive heat accumulation.

Results:

- Controlled Heat Generation:

The high-pressure coolant effectively managed heat, preventing thermal damage to both the workpiece and the Metal Cutter. - Extended Tool Life:

The AlTiN coating and optimized cutting parameters significantly extended the Metal Cutter’s lifespan, reducing the frequency of tool changes. - Consistent Quality:

Achieved precise, clean cuts in titanium alloys, meeting the demanding quality standards of the aerospace industry.

Insights:

Machining titanium alloys requires careful consideration of tool selection, cutting parameters, and cooling strategies. Utilizing high-quality coatings, maintaining low cutting speeds, and ensuring effective coolant delivery are essential for managing heat and extending Metal Cutter life in challenging materials.

Data Table 7: User Case Summaries and Key Learnings

| Case Study | Material | Metal Cutter Type | Key Adjustments | Outcomes | Key Learnings |

|---|---|---|---|---|---|

| Stainless Steel CNC Lathe Machining | Stainless Steel | Single-flute TiAlN-coated thread mill | Reduced RPM, adjusted feed rate, high-pressure coolant | Improved surface finish, extended tool life, reduced downtime | Importance of tool coating and parameter optimization |

| Aerospace Component Complex Machining | Various Aerospace Alloys | Multifunctional Metal Cutter | Adaptive toolpath, rigid fixturing | Enhanced precision, improved efficiency, consistent quality | Benefits of multifunctional tools and advanced programming |

| Titanium Alloy Cutting | Titanium Alloys | Single-flute AlTiN-coated thread mill | Low spindle speed, minimal feed rate, high-pressure coolant, multi-pass approach | Controlled heat, extended tool life, precise cuts | Critical role of cooling and careful parameter management |

Recommended Resources

To master the use of Metal Cutters in CNC machining, continuous learning and access to reliable resources are essential. Below are some recommended resources that can help you deepen your knowledge, stay updated on the latest technologies, and connect with industry experts.

Supplier Recommendations

Choosing the right suppliers ensures access to high-quality Metal Cutters and reliable customer support.

- Sandvik Coromant:

Renowned for their extensive range of cutting tools, including thread mills and high-precision end mills. Sandvik offers excellent tool coatings and innovative tool geometries. - Kennametal:

Offers a wide variety of Metal Cutters tailored for different materials and applications. Their tools are known for durability and performance in demanding environments. - ISCAR:

A leading provider of cutting tools, ISCAR offers innovative solutions for CNC machining, including advanced thread mills and multi-functional cutters. - Walter Tools:

Known for their high-performance cutting tools, Walter Tools provide solutions for a range of materials, emphasizing tool longevity and precision.

Online Learning Resources

Enhance your CNC machining skills and Metal Cutter knowledge through comprehensive online resources.

- Udemy and Coursera:

Offer courses on CNC machining, tool selection, and advanced machining techniques. These platforms provide both beginner and advanced level content. - YouTube Channels (e.g., NYC CNC, Titans of CNC):

Provide practical tutorials, tool reviews, and machining tips. Visual learning can be especially helpful for understanding toolpath strategies and Metal Cutter usage. - Manufacturer Webinars:

Many Metal Cutter suppliers host webinars covering tool selection, cutting parameter optimization, and new technology introductions. Participating in these can provide direct insights from industry experts.

Industry Conferences and Trade Shows

Networking and staying updated on the latest advancements can be achieved through attending industry events.

- IMTS (International Manufacturing Technology Show):

One of the largest manufacturing trade shows, featuring the latest in CNC technology, Metal Cutters, and machining software. - EMO Hannover:

A leading trade fair for the metalworking industry, offering insights into new tools, machinery, and industry trends. - MachTech:

Focuses on manufacturing and machining technologies, providing opportunities to see the latest Metal Cutters and CNC innovations in action.

Technical Publications and Journals

Stay informed about the latest research, trends, and best practices in CNC machining and Metal Cutter technology.

- Modern Machine Shop:

Covers a wide range of topics related to machining, including tool selection, process optimization, and industry news. - Manufacturing Engineering:

Offers in-depth articles on machining techniques, tool technologies, and manufacturing strategies. - CNC Cookbook:

Provides practical advice, tutorials, and reviews specifically for CNC machinists and Metal Cutter users.

Online Communities and Forums

Engage with other machinists, share experiences, and seek advice through online communities.

- Practical Machinist Forums:

A vibrant community where professionals discuss CNC machining, Metal Cutters, troubleshooting, and more. - Reddit (r/CNC):

A subreddit dedicated to CNC machining, offering a platform to ask questions, share projects, and learn from others. - LinkedIn Groups:

Join groups focused on CNC machining and Metal Cutting technologies to network with industry peers and stay updated on trends.

Data Table 8: Recommended Learning and Networking Resources

| Resource Type | Specific Examples | Benefits |

|---|---|---|

| Supplier Websites | Sandvik Coromant, Kennametal, ISCAR, Walter Tools | Access to high-quality Metal Cutters, technical support, and latest product information |

| Online Courses | Udemy CNC Machining, Coursera Manufacturing | Structured learning paths, beginner to advanced levels |

| YouTube Channels | NYC CNC, Titans of CNC | Visual tutorials, practical machining tips |

| Industry Conferences | IMTS, EMO Hannover, MachTech | Networking, live demonstrations, latest innovations |

| Technical Journals | Modern Machine Shop, Manufacturing Engineering, CNC Cookbook | In-depth articles, research, best practices |

| Online Forums | Practical Machinist, Reddit r/CNC | Community support, troubleshooting, experience sharing |

| LinkedIn Groups | CNC Machining Professionals, Metal Cutting Technologies | Networking, industry insights, professional growth |

Conclusion: How the Right Metal Cutter Enhances CNC Machining Value

Mastering the use of the right Metal Cutter in CNC machining is a journey that combines knowledge, experience, and continual adaptation to new technologies. The Metal Cutter is more than just a tool—it’s the cornerstone of precision, efficiency, and quality in modern manufacturing.

Enhancing Precision and Quality

Choosing the appropriate Metal Cutter ensures that every cut is accurate and every thread is consistent. Precision is paramount in industries like aerospace, medical devices, and automotive, where even minor deviations can lead to significant issues. A well-selected Metal Cutter, matched with optimized cutting parameters, guarantees that components meet exacting standards and perform reliably in their applications.

Boosting Efficiency and Productivity

Efficiency in CNC machining is directly linked to the effectiveness of the Metal Cutter. High-performance cutters reduce machining time, allow for higher feed rates, and minimize tool changes. This leads to increased productivity, enabling manufacturers to meet tight deadlines and handle high-volume production runs with ease. Moreover, extended tool life means fewer interruptions for tool changes, further enhancing operational efficiency.

Reducing Costs and Waste

Investing in high-quality Metal Cutters may seem costly upfront, but the long-term savings are substantial. Tools that last longer and maintain sharpness reduce the frequency of replacements, lower downtime, and decrease material waste due to broken or dull tools. Efficient cutting processes also minimize energy consumption and coolant usage, contributing to cost savings and more sustainable manufacturing practices.

Adapting to Diverse Materials and Applications

The versatility of Metal Cutters allows machinists to handle a wide range of materials, from soft aluminum to tough titanium and Inconel. This adaptability is crucial in today’s dynamic manufacturing environments, where flexibility and the ability to switch between different projects and materials quickly are valuable assets. Specialized Metal Cutters and advanced coatings enable precise machining across diverse applications, ensuring that machinists can meet varied production demands without compromising quality.

Embracing Technological Advancements