CNC (Computer Numerical Control) manufacturing has revolutionized the industry with its precision, speed, and repeatability. Among many fabrication methods employed in CNC machining, bead blasting constitutes a crucial part. This method is utilized to finish metal surfaces by bombarding them with fine glass beads under high pressure without damaging the surface textures. In this article, we will delve into an elaborate understanding of bead blasting as an integral process within CNC machining.

Bead blasting finds its relevance across multiple applications such as removing paint, rust, or other surface contaminants and deburring & smoothing in preparation for powder coating, anodizing, etc. The result is a smooth, clean, and finely matte-textured product that provides aesthetic appearances and enhanced mechanical properties.

The ensuing paragraphs provide insights on how to prepare, perform, and obtain optimal results from bead blasting in CNC machining operations.

1. Preparations Prior to Bead Blasting:

Before the actual procedure, a detailed inspection of the workpiece is necessary. Assessing whether it contains any deep scratches, dents, discoloration, or blocks can aid in creating an efficient bead-blasting strategy. Next, ensure you use suitable personal protective equipment like gloves, masks, eyewear, and aprons – never undermine the importance of safety when dealing with highly pressurized machines.

2. Choosing Appropriate Media:

Glass beads are commonly used due to their compatibility with most metals. They come in various sizes, giving different ranges of roughness – smaller beads often produce smoother finishes while larger ones tend to give more aggressive cuts. Your selection must be aligned with your project requirements.

3.Blast Cabinet Preparation:

In bead blasting, a blast cabinet acts as a controlled environment where all action takes place. It should contain enough medium for constant feed during operation without overflowing distractions and waste production. Regular maintenance is also essential to avoid clogging and humidity interference.

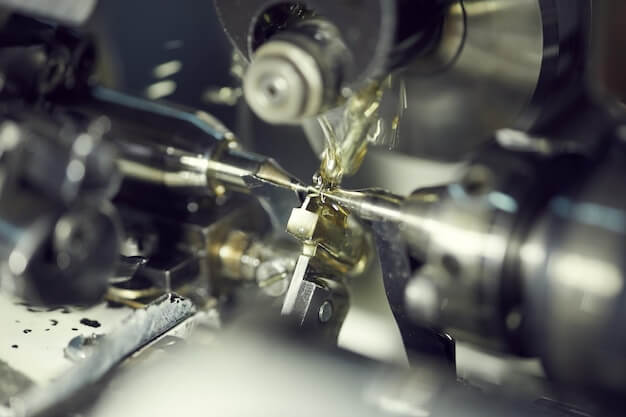

4.The Bead Blasting Process:

This procedure involves bombarding the workpiece with high-velocity beads aimed straight or varying angles, based on necessity. The glass beads effectively ‘peen’ the surface, closing microscopic holes and fissures preventing fatigue failure in products such as aerospace components.

5.Post-Blasting Activities:

After blasting, clean the surface thoroughly to remove residual particles left from the process. Follow-up treatments like anodizing or coating can be conducted to further enhance the product’s final appearance and quality.

The crux of successful bead blasting lies in understanding its potential applications and limitations alike. It is important to note that while it offers benefits such as increased durability, improved cosmetic features, this method might not serve the purpose where rough-textured finishes are desired.

Some popular industries utilizing bead blasting include automotive for enhancing engine parts, manufacturing sector for treating metal commodities before secondary processes, jewelry industry for creating frosted appearances, and medical fields for preparation & finishing off surgical instruments and implants.

In conclusion, bead blasting plays a crucial role in CNC machining clinical accuracy combined with aesthetic enhancements. Recognized for its advantages in several domains, focus on mastering the art of bead blasting in CNC machining would reap significant dividends, increasing your overall productivity, and providing unmatched quality products.

Let’s look forward to more innovative applications of bead-blasting and advances in technology that encourage smoother automated operations within CNC machining environments. By continually learning and applying these skills, we pave the road towards engineering excellence and industrial achievement.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…