About Aluminum

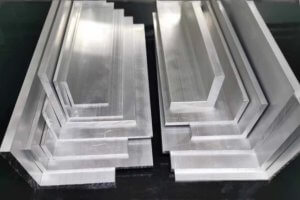

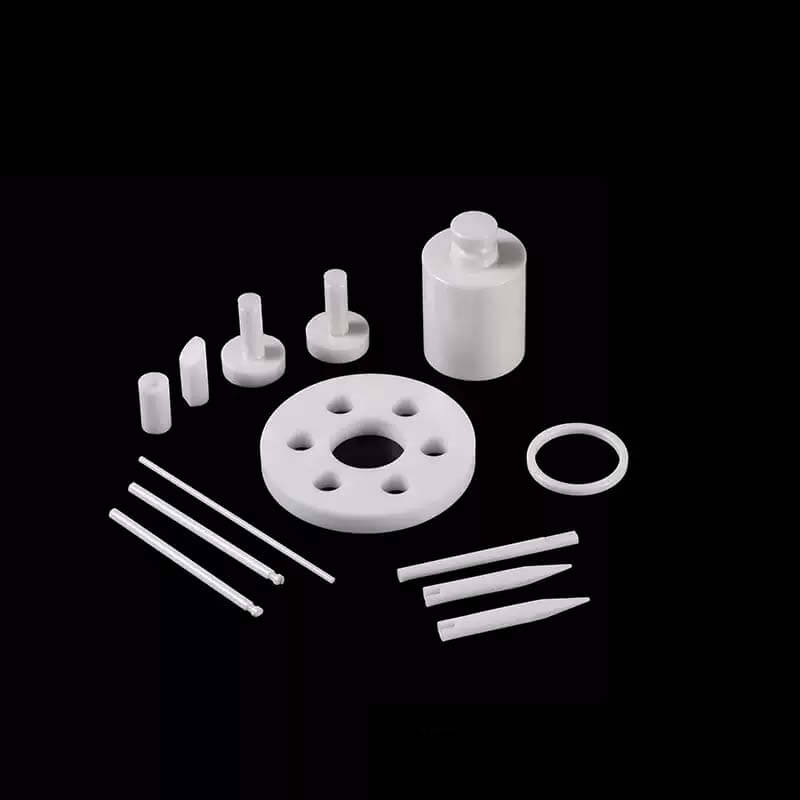

Aluminum is one of the most commonly used materials in the industry. It is a lightweight and durable metal that can be easily machined to create complex shapes and features. Aluminum also has excellent thermal and electrical conductivity, making it a popular choice for applications in industries such as aerospace, automotive, and electronics.

Aluminum comes in various grades, each with its unique set of properties and characteristics. Some of the commonly used grades in CNC machining include 6061, 7075, and 2024. 6061 is a general-purpose grade that offers good strength and machinability, while 7075 is a high-strength grade commonly used in aerospace and defense applications. 2024 is another high-strength grade that is often used in aircraft structures.

One of the benefits of using aluminum in CNC machining is its ability to be easily formed into complex shapes using various cutting techniques such as milling, turning, and drilling. It can also be anodized to improve its corrosion resistance and add decorative finishes.

In summary, aluminum is a versatile and widely used material in CNC machining, with its unique combination of properties making it suitable for a wide range of applications.