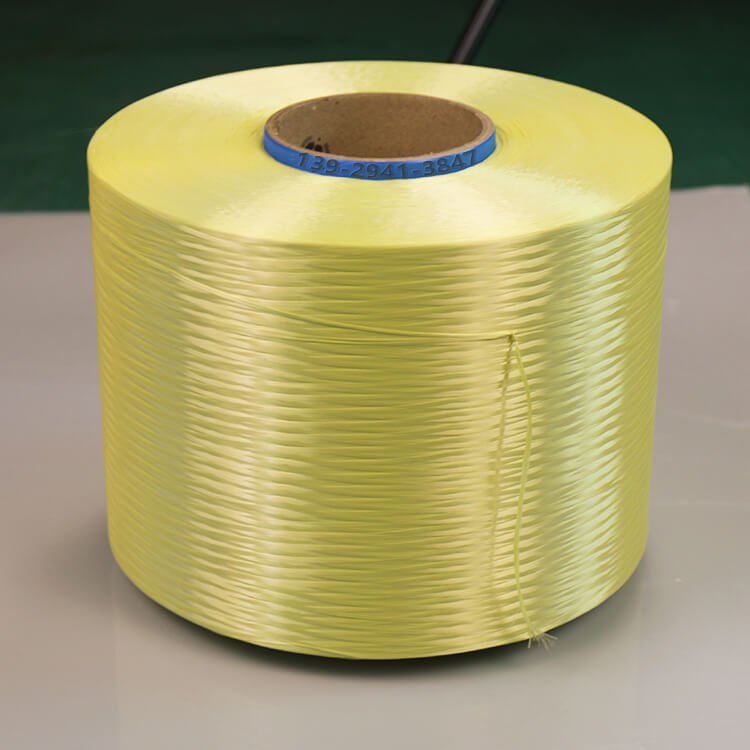

Carbon Fiber Reinforced Polymer (CFRP) is a composite material made by embedding carbon fibers within a polymer matrix. The carbon fibers, which are typically 5–10 micrometers in diameter, are composed mostly of carbon atoms. These fibers are extremely strong, lightweight, and have high stiffness, making them ideal for applications requiring high strength-to-weight ratios. The polymer matrix, often made from epoxy, polyester, or vinyl ester resins, acts as a binder to hold the carbon fibers in place and protects them from environmental damage.

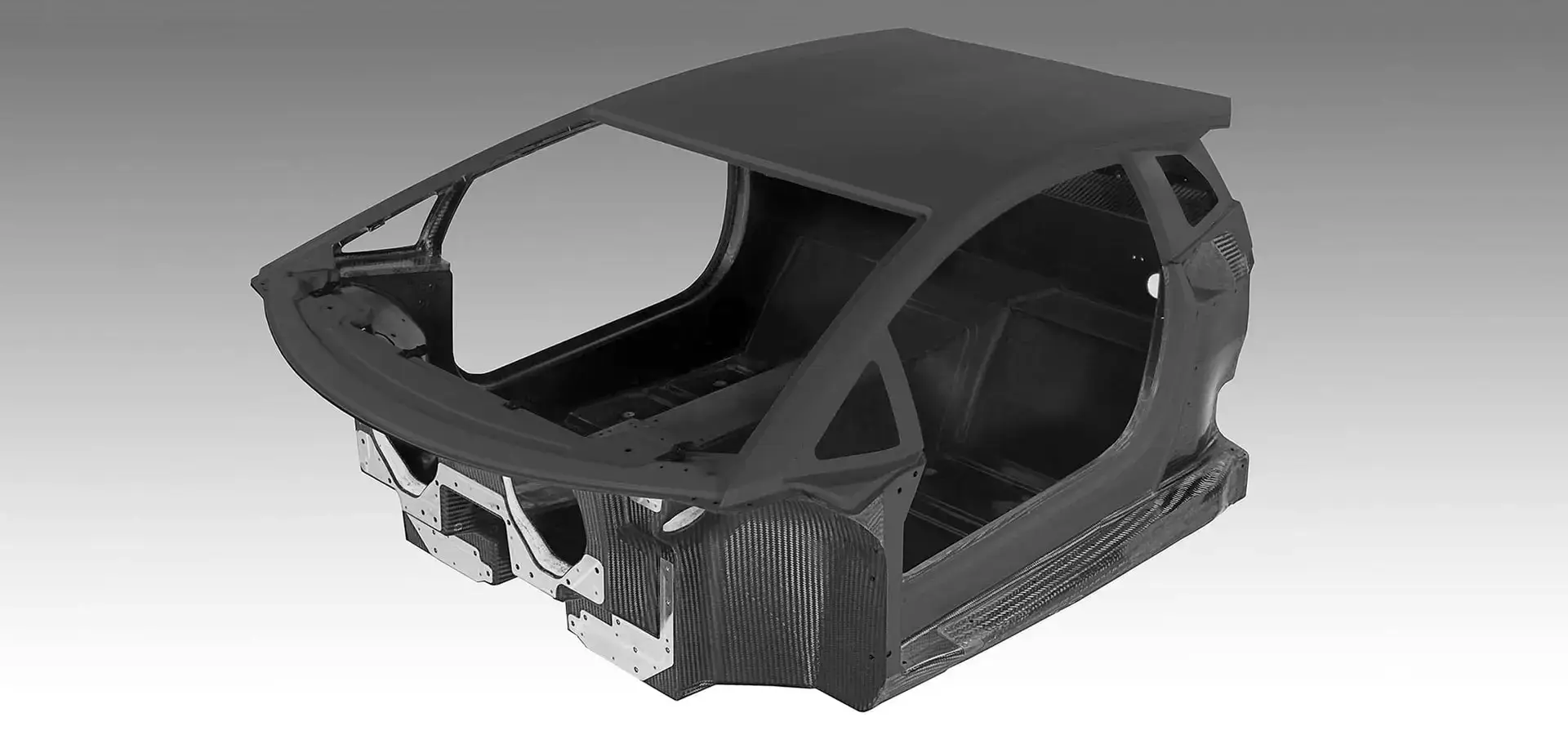

CFRP is widely used in aerospace, automotive, sports equipment, and other high-performance applications where both strength and weight are critical factors. In aerospace, for example, CFRP is used to manufacture parts of aircraft fuselages, wings, and tail sections. In automotive applications, it is utilized in the construction of car bodies, racing cars, and high-performance components. The material’s lightweight nature helps reduce fuel consumption, while its strength ensures durability and safety.

CFRP’s popularity stems from its ability to be tailored for specific applications. By varying the orientation, density, and type of carbon fibers, manufacturers can create composite materials with distinct mechanical properties suited for different uses. Despite its many advantages, CFRP also presents challenges, including high production costs and complex manufacturing processes. Nonetheless, its unique combination of lightness, strength, and durability makes it indispensable in modern engineering.

- Subtypes of Carbon Fiber Reinforced Polymer (CFRP)

CFRP can be categorized into several subtypes based on the type of carbon fiber used, the orientation of the fibers, and the specific polymer matrix. Understanding these subtypes is essential for selecting the right material for a given application.

- High-Modulus CFRP: This subtype uses high-modulus carbon fibers, which are known for their extremely high stiffness. These fibers are ideal for applications where rigidity is more important than strength, such as in satellite structures and precision instruments. The high modulus of elasticity in these fibers allows for minimal deformation under load, ensuring structural integrity in demanding environments.

- High-Strength CFRP: High-strength CFRP is made using carbon fibers that prioritize tensile strength over stiffness. These materials are often used in applications like aerospace and automotive components where both strength and lightness are crucial. The fibers used in this subtype have a lower modulus of elasticity compared to high-modulus CFRP but offer superior resistance to breakage.

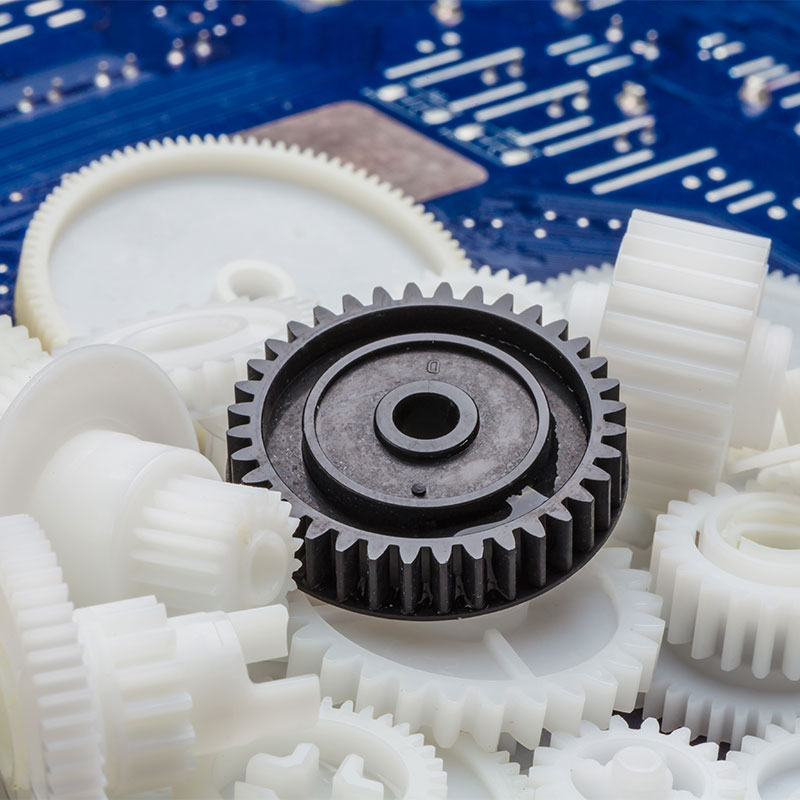

- Standard-Modulus CFRP: This is the most commonly used subtype of CFRP, balancing strength, stiffness, and cost-effectiveness. It is versatile and can be found in a wide range of applications, including sporting goods, general automotive parts, and consumer electronics. Standard-modulus CFRP offers a good balance between performance and manufacturability, making it suitable for mass production.

- Toughened CFRP: In this subtype, the polymer matrix is toughened, often with additives like thermoplastic particles, to improve the material’s impact resistance and damage tolerance. Toughened CFRP is particularly useful in aerospace applications, where components are exposed to high impact forces and the risk of damage is significant.

Each subtype of CFRP offers unique advantages and is chosen based on the specific requirements of the application. The selection process considers factors like the load-bearing needs, environmental conditions, and the cost constraints of the project.