About HDPE

The utilization of high-density polyethylene (HDPE) is widespread in CNC machining due to its exceptional qualities and versatility.

HDPE, derived from petroleum, belongs to the category of thermoplastic polymers. Its noteworthy feature is a remarkable strength-to-density ratio, making it an ideal choice for applications that prioritize strength while minimizing weight. Furthermore, HDPE exhibits impressive resistance against chemical substances, rendering it highly suitable for deployments involving exposure to harsh chemicals.

The material’s distinguishing characteristic lies in its low coefficient of friction. This attribute makes HDPE particularly advantageous in scenarios where components must smoothly slide against each other, minimizing wear and tear. Additionally, HDPE possesses exceptional resistance to moisture, positioning it as an excellent option for outdoor applications.

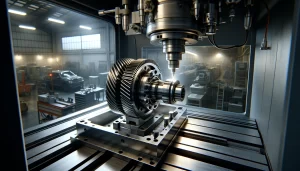

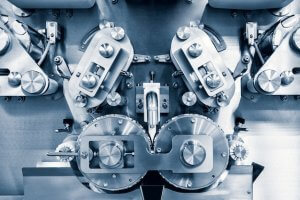

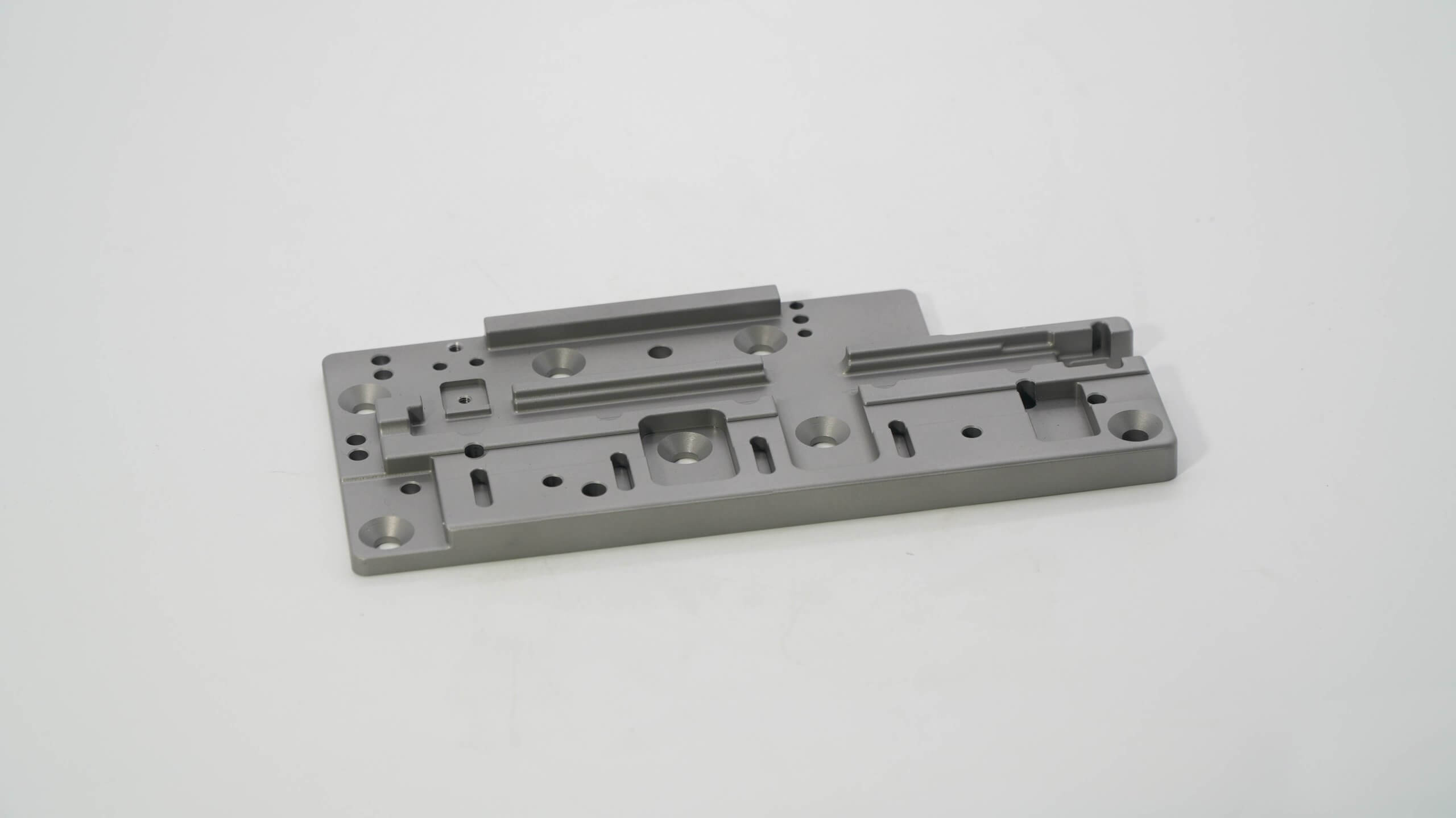

In CNC machining, HDPE stands out as a readily machinable plastic material capable of producing parts in diverse shapes and sizes. HDPE Machining allows for precise fabrication of complex components with excellent dimensional stability. Gears, bushings, bearings, and a wide array of other products can be successfully fabricated using HDPE. The material’s appeal stems from its unique combination of strength, chemical resistance, and low friction.

High-density polyethylene (HDPE) emerges as an invaluable material in CNC machining, cherished for its remarkable attributes, encompassing strength, chemical resilience, and reduced friction. Its versatility and wide-ranging applications solidify its position as a go-to choice in various industries.