About Delrin

Delrin, also known as polyoxymethylene (POM), is a high-performance engineering thermoplastic widely recognized for its exceptional strength, stiffness, and dimensional stability. It is an acetal homopolymer resin developed by DuPont and is a preferred plastic material for many industrial applications due to its low friction, wear resistance, and high fatigue endurance. Delrin exhibits excellent resistance to moisture, solvents, and oils, making it suitable for environments where exposure to chemicals or moisture is prevalent.

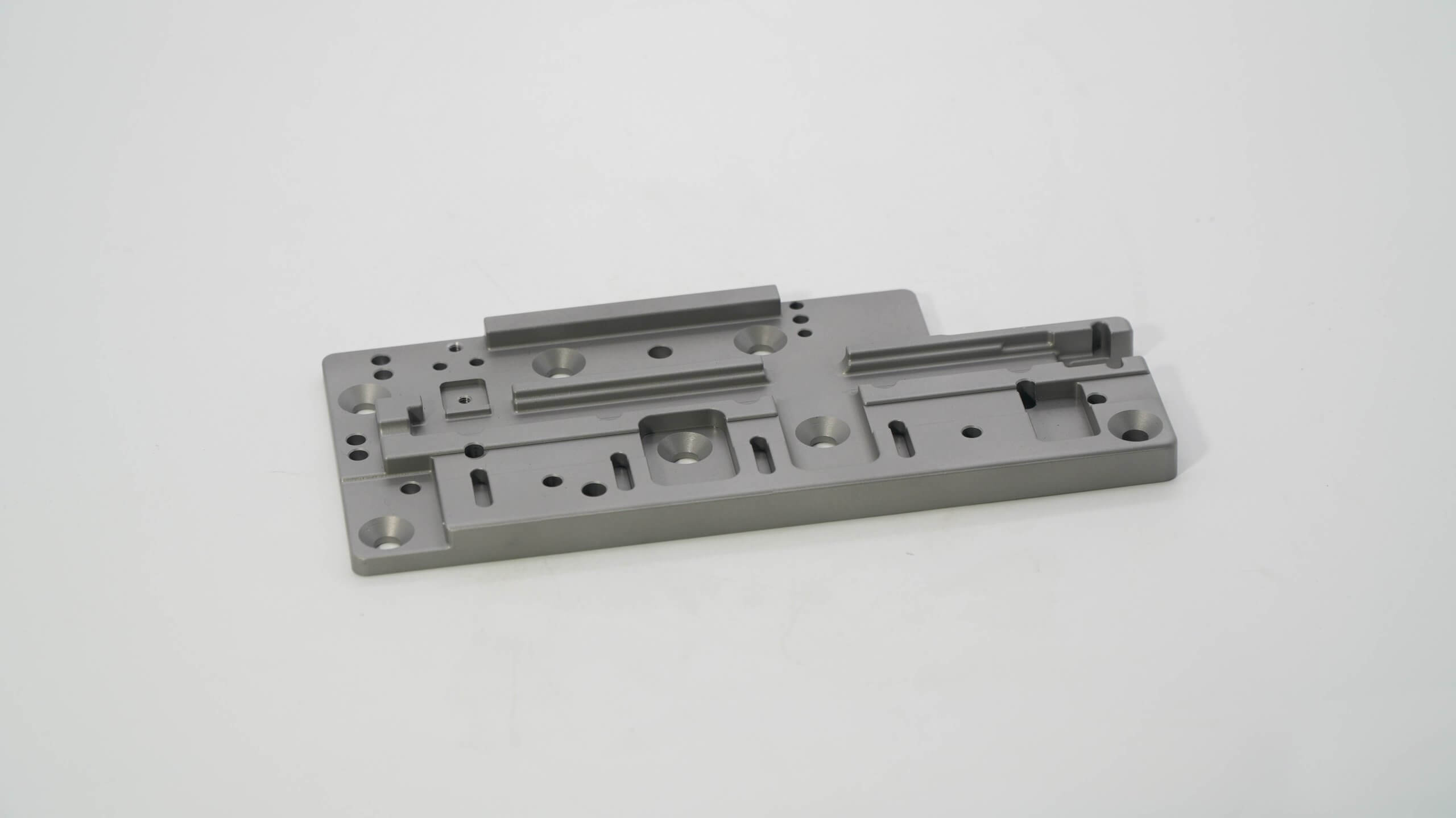

This material is commonly used in precision parts, such as gears, bearings, and automotive components, where mechanical strength and dimensional accuracy are crucial. Delrin’s ability to maintain its properties over a wide temperature range, from -40°C to 120°C, adds to its versatility. It is also FDA-approved for certain food and medical applications, further broadening its scope of use. Additionally, its machinability allows manufacturers to produce complex components using methods like CNC machining, injection molding, and extrusion.