About Titanium

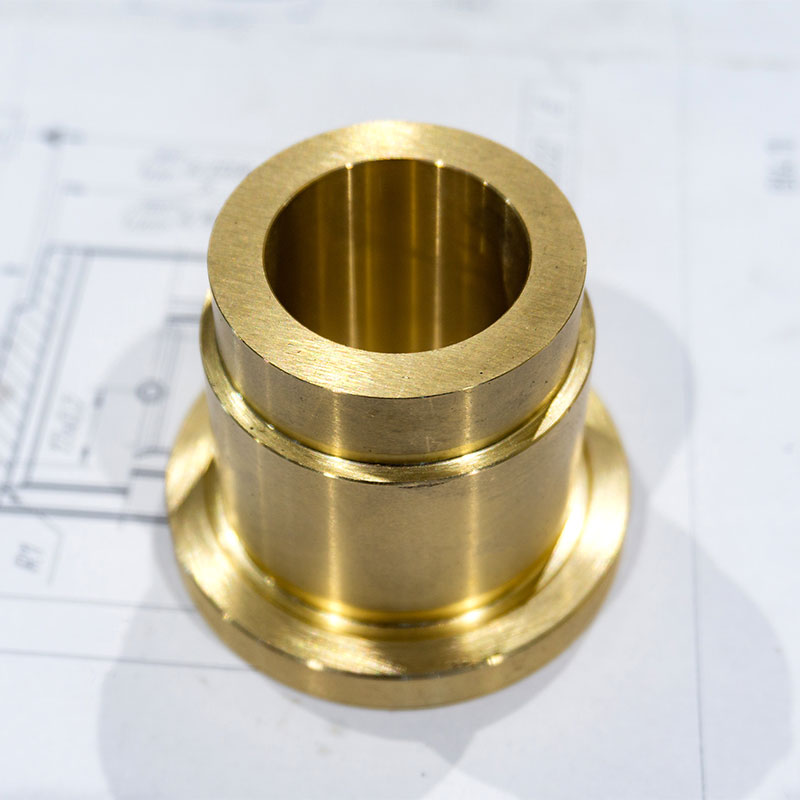

Titanium is a popular material in the world of CNC machining due to its impressive properties. It is a lightweight and strong metal with excellent corrosion resistance, making it suitable for a wide range of applications. Additionally, titanium has high melting and boiling points, low thermal conductivity, and high ductility and toughness, which makes it a popular choice for high-temperature and high-stress environments.

There are various types of titanium available, each with their unique properties and applications. Some common types of titanium used in CNC machining include grade 5 titanium (Ti-6Al-4V), grade 2 titanium (Ti-Grade 2), and grade 23 titanium (Ti-6Al-4V ELI). Each of these types has a different chemical composition, and therefore, their mechanical properties and machinability may vary.

Overall, titanium is a versatile material that is used in many different industries, such as aerospace, medical, and automotive, among others. Its ability to withstand harsh environments and resist corrosion make it a preferred material for many applications in the modern world. However, titanium can be challenging to machine due to its high hardness, low thermal conductivity, and low thermal expansion coefficient, which can cause tool wear and deformation of the workpiece. Therefore, proper selection of cutting tools, machining parameters, and coolant systems is critical for successful CNC machining of titanium.