Titanium oxide ceramics, primarily composed of titanium dioxide (TiO₂), are advanced ceramic materials known for their exceptional electrical, optical, and mechanical properties. Titanium oxide is widely used in industries due to its high dielectric constant, chemical stability, and excellent corrosion resistance. These properties make titanium oxide ceramics highly suitable for electronic applications, including capacitors, insulators, and resistors. In addition, they find applications in optics as they exhibit high refractive indices, making them useful in the production of lenses and optical coatings.

Titanium oxide ceramics are particularly resistant to acidic and oxidizing environments, which makes them well-suited for chemically harsh applications. They also possess moderate mechanical strength and thermal stability, which allows them to perform in high-temperature environments up to around 1000°C. Their low electrical conductivity makes them effective electrical insulators, commonly applied in electrical devices and circuits that require high insulation properties. Titanium oxide is also photoactive, which is a significant benefit for applications in photocatalysis, such as in water purification and environmental cleaning technologies.

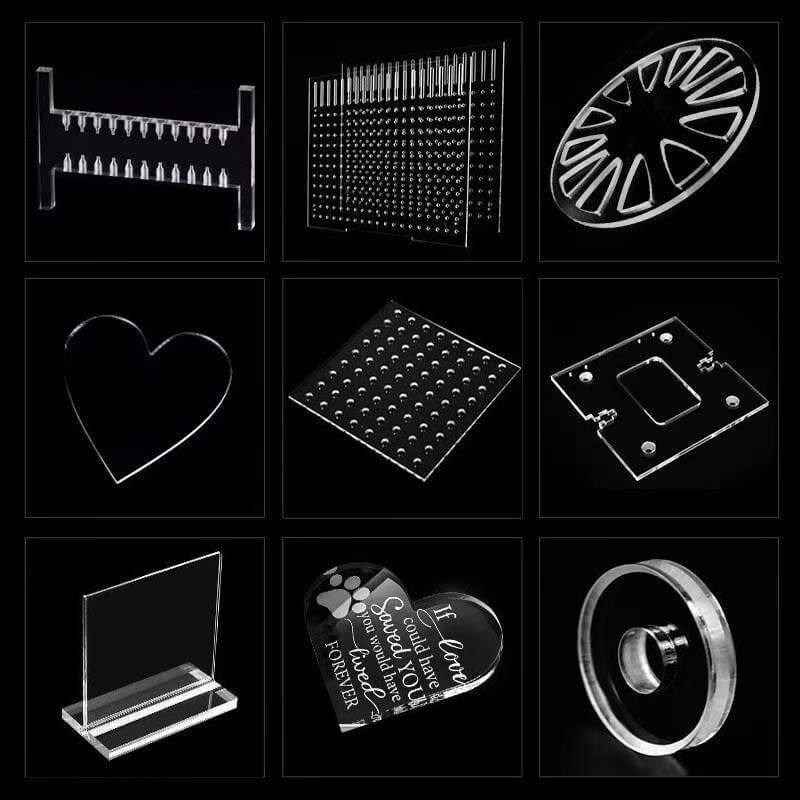

However, titanium oxide ceramics can be brittle and challenging to machine, requiring specialized equipment and techniques. CNC machining of titanium oxide ceramics must be done carefully to avoid fracturing or damaging the material. This brittleness presents a challenge in machining applications, making it essential to use precision tools and methods to achieve accurate dimensions and avoid material loss. The applications of titanium oxide ceramics extend to industries such as electronics, optical equipment, environmental technology, and even biomedical devices due to their biocompatibility.