Importance of Precision in CNC Machining

Precision is an fundamental component in the field of Computer Numerical Control (CNC) machining. It entails producing parts that are not only accurate but also consistent, which is crucial for applications where even the smallest deviation can result in substandard performance or complete failure. A myriad of factors impact precision in CNC machining such as machine calibration and regular maintenance, cutter selection and tooling, material properties and handling, as well as trimming cutting parameters down to optimal settings. Employing techniques like designing proper fixture and workpiece setups, optimizing tool paths and programming, along with effective cooling and lubrication methods, can truly maximize this precision. Regular inspections, apt choice of cutting tools for specific jobs, ensuring material stability during machining process and fine-tuning cutting parameters constitutes high precision practices in the craft. To illustrate, aerospace components – known for requiring extremely high precision – can be proficiently manufactured using these strategies.

Precision Machining of Aerospace Components

The aerospace industry demands an exceptionally high level of precision for its components, given the critical nature of aerospace applications. Precision machining plays a pivotal role in meeting these stringent requirements, ensuring that parts not only fit perfectly but also perform flawlessly under extreme conditions. This section delves into the significance of precision machining in the aerospace sector and highlights key considerations for achieving unparalleled accuracy.

Importance in the Aerospace Industry

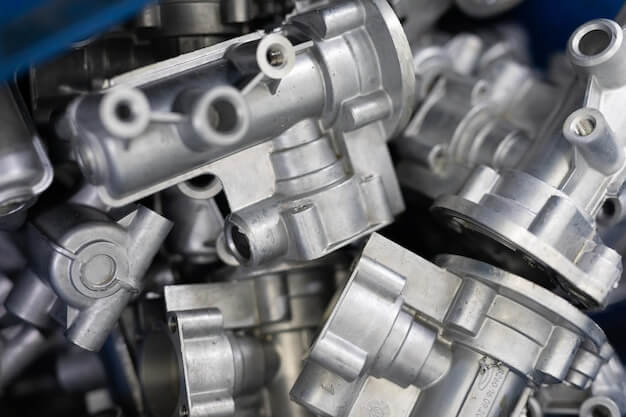

Precision machining is crucial in the aerospace industry due to the high-quality standards and strict industry regulations. The process ensures the production of high-precision parts that are essential for the safety and functionality of aerospace vehicles. Components such as landing gear parts, engine components, and airframe structures require meticulous attention to detail, making precision machining indispensable.

Key Considerations for Aerospace Precision Machining

- Material Selection: Choosing the right material is vital for aerospace components. Materials like aluminum, titanium, and stainless steel are commonly used for their strength-to-weight ratio and durability.

- Finishing Options: Surface finishes play a significant role in the performance and longevity of aerospace parts. Options like anodizing, plating, and powder coating are considered to enhance part appearance and functionality.

- Design Optimization: Efficient design is critical for reducing waste and machining time. Incorporating features that facilitate easier machining without compromising part integrity is essential.

- Quality Assurance: Adhering to aerospace industry standards and conducting rigorous quality checks ensure that parts meet the required specifications and performance criteria.

| Aspect | Consideration |

|---|---|

| Material Selection | Aluminum, titanium, stainless steel |

| Finishing Options | Anodizing, plating, powder coating |

| Design Optimization | Efficient design for reduced waste and machining time |

| Quality Assurance | Adherence to standards and rigorous quality checks |

By focusing on these key considerations, precision machining ensures the production of aerospace components that not only meet but exceed the high expectations of the industry. This meticulous approach to manufacturing is what makes precision machining an indispensable part of aerospace engineering.

Other Articles You Might Enjoy

- Maximizing Precision in CNC Machining: Techniques and TipsPrecisionMaximizing Precision in CNC Machining: Techniques and Tips

Introduction to CNC Machining and Its Role in Precision Manufacturing CNC (Computer Numerical Control) machining is a pivotal technology in the field of precision manufacturing. This automated process controls machine…

- Maximizing Precision: China CNC Machining for Gearboxes

The Role of CNC Machining in Gearbox Manufacturing Gearboxes are integral to the functionality of a wide range of machinery, acting as the cornerstone of power transmission systems. The role…

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…