Introduction to Precision Machining Services

Precision machining services, known for their extreme accuracy and high-quality outputs, play a pivotal role in enhancing product quality and efficiency. This advanced production process employs computerized tools and techniques to remove material from a workpiece, ensuring the piece perfectly matches its design specifications. Precision machinery contributes significantly to industries ranging from aerospace to electronics, creating complex parts with unmatched precision. Overall, these services help businesses maintain tight tolerances, enhance functionality, improve consistency, and reduce wastage.

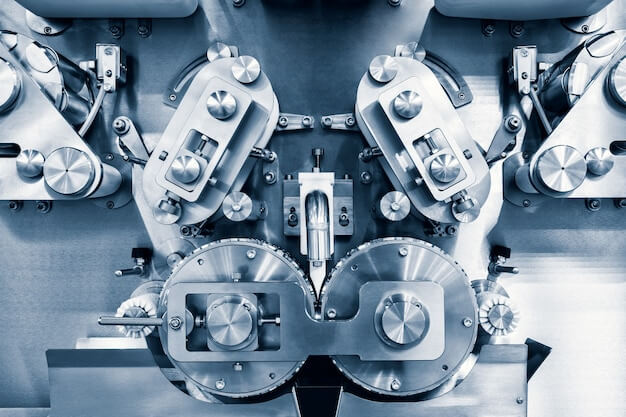

Understanding the Concept of Precision Machining

Precision machining is a process used to produce accurate components with high tolerances and excellent surface quality by removing materials from a workpiece. It involves a combination of several or all of the turning, milling, drilling, gear cutting, honing, grinding processes, and other steps. Partnering with a Precision Machining Service can ensure the highest level of precision and quality in manufacturing processes.

Enhancing Product Quality Through Precision Machining

Precision machining plays a pivotal role in achieving high-quality products. It is an advanced procedure that removes excess material from workpieces while controlling the output to a very meticulous degree of accuracy. This precision not only ensures consistency and repeatability but also enhances product quality by reducing part variability, increasing production speed, and minimizing waste.

- Consistency and Repeatability: With precision machining, identical components can be produced repeatedly with minimal deviations, consequently enhancing the overall product quality.

- Reduced Part Variability: Precision machining minimizes the chances of error and thus lowers part variability which ultimately translates to improved product quality.

- Increase in Production Speed: The use of precision machines facilitates faster production cycles without compromising on the design or functional quality of the products.

- Minimizing Waste : By ensuring precise control over material removal, precision machining helps reduce wastage, leading to cost-effective and efficient manufacturing processes.

An example would be the aerospace industry where precision machining is widely utilized for making intricate parts of aircraft. To meet exceedingly demanding specifications and tolerances, these components are meticulously machined to ensure their reliability and durability. Hence, precision machining significantly improves the safety, longevity, and performance standards of airspace products.

Efficiency in Production via Precision Machining

Precision machining services significantly increase efficiency during production through a variety of methods. Firstly, precision machinery is designed to operate quickly and accurately, reducing production time considerably while maintaining consistent quality. Secondly, precise tools lower the rate of errors that can lead to costly product rejections or revisions, thereby enhancing manufacturing output. Lastly, advanced technologies integrated into these machines allow for automation, which reduces manual intervention and increases throughput.

An example demonstrating this improved efficiency involves a car manufacturing plant integrating precision CNC (Computer Numerical Control) machines. The use of such high-accuracy machines has enabled faster and more accurate fabrication of car parts like engine components, leading to an increased production rate with less waste due to errors. Consequently, the overall efficiency of vehicle production was dramatically enhanced.

Advantages of Using Precision Machining Services

Precision machining services offer numerous advantages, especially to manufacturers. They ensure the production of parts with exact measurements and fine details, which contribute to improved product quality. Manufacturers benefit from the high accuracy level achieved by advanced technological tools used in precision machining, reducing waste and increasing efficiency. Moreover, process automation significantly minimizes human errors and accelerates the manufacturing speed.

From a consumer’s perspective, products made using precision machining processes are reliable due to their enhanced durability. At the same time, they adhere closely to specified design standards, ensuring an optimum fit and function. Consumers also appreciate the aesthetic appeal brought about by precision cut, neat finishes typically characterized by items produced through these methods.

- High Production Accuracy: Manufacturing errors are drastically reduced, resulting in less wastage of materials

- Faster Production Speed: Automation use hastens the manufacturing process, meeting high volume demands promptly

- Improved Product Quality: The application ensures precisely finished products thereby enhancing their longevity

- Better Design Adherence: Precision machining allows for strict adherence to specified complex designs making the final products viable for consumers’ practical usage

Real-Life Applications of Precision Machining

Precision machining services pervade our everyday life, with numerous applications enhancing both product quality and efficiency. For instance, it’s in the manufacturing of intricate pieces for wristwatches, components for electronic devices like smartphones or computers, parts for vehicles from automobiles to spacecrafts – virtually any object requiring smaller, complex, precise manufactured parts.

This precision contributes significantly to the overall quality and functionality of products we utilize daily. The automobile industry is a clear example where precision machined components, such as engine parts, provide unmatched efficiency and balance to ensure that our rides are smooth, safe and fuel-efficient. Similarly, the electronic industry depends heavily on accuracy for key aspects like performance, longevity and energy consumption.

In essence, without precision machining:

- We wouldn’t have high-quality, reliable cars or planes;

- The gadget you’re using to read this article may not even exist; and,

- Many fields from medical to aerospace would be severely compromised by inefficiency and lower standards.

Indeed, these real-life applications underscore how integral this approach is to modern life.

Other Articles You Might Enjoy

- Next-Gen CNC Machining: From Concept to Reality in Aerospace Parts

Introduction to CNC Machining and its Next-Gen Advancements in Aerospace CNC (Computer Numerical Control) machining is a digital manufacturing technology that deploys pre-programmed software to manipulate machine shop tools. This…

- The Advantages of Using Silicon Nitride in High-Speed CNC Machining Applications?

Introduction to CNC Machining and Silicon Nitride In high-speed Computer Numerical Control (CNC) applications, the use of ideal materials is critical for optimum performance. One such material that has proven…

- Revolutionizing CNC Machining for High-Performance Electric Vehicles

Revolutionizing CNC Machining for High-Performance Electric Vehicles CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of machinery and tools, facilitating preciseness in…