Introduction to CNC Machining for Assembled Crankshafts

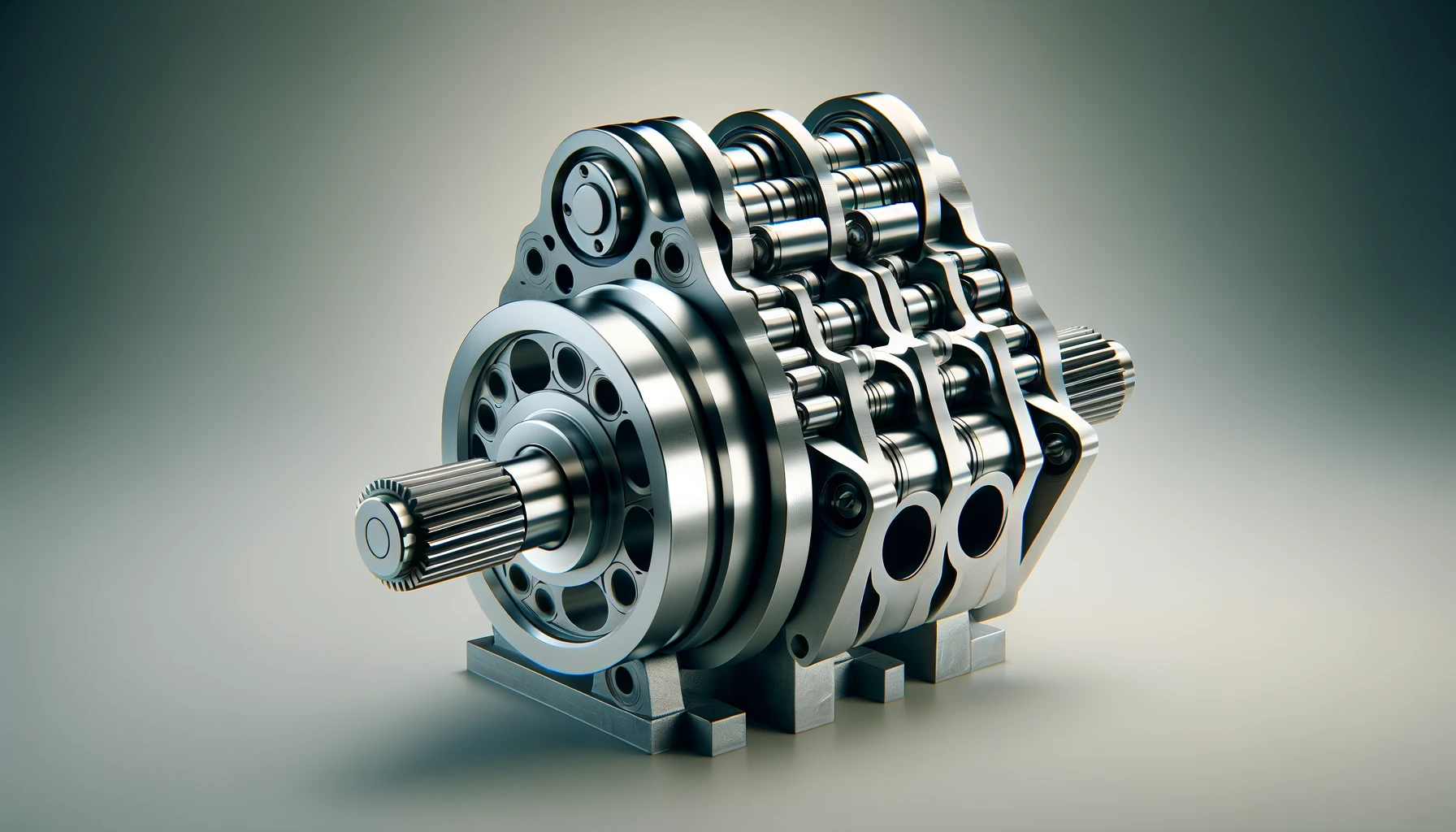

CNC (Computer Numerical Control) machining represents a pinnacle of precision engineering, a process that has revolutionized the manufacturing world. Assembled crankshafts, which are at the heart of any engine, demand the utmost precision and care in their production. The processing requirements of the crankshaft are also very complex. In order to solve this problem, the supplier provides online CNC service to facilitate customers to upload detailed processing drawings online to avoid errors in understanding requirements.The intricacies involved in their CNC machining require an understanding of the process itself, the materials used, and the engineering challenges that come with it. In this exploration, we delve into the multifaceted world of CNC machining for assembled crankshafts, highlighting the technical hurdles and the innovative solutions that leading Chinese manufacturers employ to navigate this complex landscape.

Assessing the Technical Challenges of CNC Crankshaft Production

The production of assembled crankshafts via CNC (Computer Numerical Control) machinery incorporates a multitude of technical complexities. These challenges encompass the entire process, from initial design conceptualization to the final quality control checks. One of the primary hurdles is achieving the strict tolerance levels required for assembled crankshafts. The precision of the crankpin and main journal dimensions must be within micrometers to ensure the proper functioning of the engine. Additionally, the dynamic balance of the crankshaft must be maintained to prevent excessive vibration during operation. This balance is a critical factor in the lifespan of the engine, as imbalances can lead to premature wear and tear of engine components.

Another significant challenge lies in the CNC programming phase. Assembled crankshafts are not uniform and feature various contours and profiles that require sophisticated software algorithms for precise machining. The programming must account for factors such as tool path, speed, feed rate, and the sequence of operations to optimize the process and prevent material waste.

In a case study focusing on the production of assembled crankshafts for high-performance engines, one leading Chinese manufacturer had to devise a multi-stage machining process. This process involved using specialized diamond-coated tools to achieve the desired surface finish and dimensional accuracy. The success of this approach was evident in the extended lifecycle of the crankshafts and the enhanced performance of the engines.

Material Considerations in CNC Machining Assembled Crankshafts

Selecting the appropriate material for CNC machining assembled crankshafts is pivotal to the component’s performance and durability. The materials used must withstand the high stresses and fatigue associated with the operation of internal combustion engines. Traditionally, materials such as forged steel and ductile iron are preferred due to their high tensile strength and resistance to wear. However, material innovation continues, and newer alloys are being tested for their suitability in crankshaft production.

One such material is a high-grade titanium alloy known for its exceptional strength-to-weight ratio. Utilizing this material in a CNC context presents unique challenges, such as controlling the heat generation during machining, as titanium can be highly reactive at elevated temperatures. Manufacturers must employ advanced cooling techniques and adjust cutting speeds accordingly. A notable example comes from a Chinese machining manufacturer that implemented a cryogenic cooling system, using liquid nitrogen to mitigate heat effects and prevent material warpage during the CNC machining of titanium crankshafts.

Precision Engineering: Tolerances and Testing in CNC Processes

Achieving and maintaining the tight tolerances required for assembled crankshafts is a testament to precision engineering. The CNC machining process must ensure that every surface finish and dimensional attribute is within the allowable limits to guarantee the assembled crankshaft’s functionality and longevity. To illustrate, a leading Chinese manufacturer adopted a precision testing regimen using coordinate measuring machines (CMMs) and laser scanners to verify dimensions and surface finishes with sub-micron accuracy, thereby ensuring each crankshaft meets rigorous performance standards.

Tooling Innovations for Assembled Crankshaft Machining

The tooling used in the CNC machining of assembled crankshafts has evolved significantly, driven by the need to increase efficiency and precision. Modern tooling solutions have to be both tough enough to handle the hard materials used for crankshafts and flexible enough to adapt to their complex geometries. Advances in tooling design have led to the development of multi-point cutting tools that can perform several machining processes simultaneously, reducing cycle times and improving productivity.

One such innovation involves the use of PCD (Polycrystalline Diamond) tooling for finishing operations on assembled crankshafts. These tools provide a superior surface finish and possess a longer service life, making them cost-effective for large-scale production. A Chinese manufacturer utilized PCD tooling to streamline their production process for a high-volume order of assembled crankshafts, resulting in a 30% reduction in machining time while maintaining high-quality standards.

Maintaining Efficiency While Overcoming CNC Machining Barriers

Maintaining efficiency in the face of the aforementioned challenges requires a meticulous approach to the CNC machining process. Manufacturers must optimize every aspect, from the initial programming to the final inspection. For instance, a Chinese machining company streamlined their production process by integrating an automated tool change system and adaptive control software, which dynamically adjusts cutting conditions in real-time to prevent tool wear and ensure consistent quality, thereby reducing downtime and enhancing overall efficiency.

Case Study: Optimizing Assembled Crankshaft Production in China

To demonstrate the effectiveness of these strategies, consider a case study from a renowned Chinese machining firm. Faced with the challenge of producing high-volume, high-quality assembled crankshafts for a new line of eco-friendly engines, the company implemented a lean manufacturing approach. By redesigning the workflow, investing in state-of-the-art CNC equipment, and employing advanced simulation software, the firm was able to cut production times by 30% while maintaining the exacting standards required for these critical engine components.

Other Articles You Might Enjoy

- Innovative Approaches to CNC Assembled Crankshafts by Leading China Machining Manufacturers

Introduction to CNC Machining in Crankshaft Production Computer Numerical Control (CNC) machining has become an integral part of the manufacturing industry, providing unparalleled precision, efficiency, and repeatability. In the realm…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…