Introduction to Online Manufacturing Services

The advent of the digital era has paved the way for online manufacturing services, a modern revolution in the industrial sector. It involves leveraging web-based platforms to source, produce, and distribute various manufactured products. Businesses can connect with manufacturers globally, bypassing traditional hurdles such as geographic limitations or unnecessary intermediates, thus accelerating the production process while reducing costs. Additionally, concepts like 3D printing have further boosted the potential of these services, enabling production-on-demand scenarios without depending on mass production facilities. This transformation not only encapsulates technical advancements but also signifies a fundamental shift in operations strategy within the manufacturing industry.

Understanding the Complexities of Online Manufacturing Services

The process of using online manufacturing services can be quite intricate due to several factors. Firstly, one must comprehend how to accurately design and submit specifications for their product utilizing digital tools – a skill that requires both technical proficiency and sharp attention to detail. Secondly, coordinating communication between multiple parties over the internet presents its own unique challenges, requiring individuals to effectively manage virtual relationships with manufacturers, suppliers, and freight forwarders alike. Thirdly, companies need to navigate logistical complexities such as shipping, international trade regulations and quality assurance protocols in an online setting. It is crucial to successfully traverse these hurdles because mastering online manufacturing logistics can drive efficiency, reduce costs, and ultimately play a major role in a business’s success.

Navigating the Pricing Structures and Cost Estimation Process in Online Manufacturing Services

Understanding the pricing structures and cost estimation process is crucial when utilizing online manufacturing services. This involves a comprehensive approach that considers various factors influencing the final cost. Here, we delve into the components that shape the pricing structures and how customers can effectively navigate the cost estimation process in online manufacturing services.

Components of Pricing Structures

- Material Costs: The choice of material significantly impacts the overall cost, with high-performance materials like titanium being more expensive than plastics or softer metals.

- Design Complexity: Complex designs that require advanced machinery, skilled operators, and specialized tools tend to increase the cost.

- Production Volume: The volume of production affects costs, with larger volumes benefiting from economies of scale, thus reducing the cost per unit.

- Additional Services: Services such as surface finishing, assembly, or rapid prototyping can also influence the final price.

Cost Estimation Process

The cost estimation process in online manufacturing services typically involves the following steps:

- Customers upload their design files to the online platform.

- The platform automatically generates a quote, considering factors like material, design complexity, and volume.

- Customers can configure different materials, finishes, and quantities to see how these changes affect the cost.

- Free Design for Manufacturing (DfM) analysis may be provided, offering insights into manufacturability issues and potential cost savings.

Optimizing Costs with Online Manufacturing Services

| Strategy | Description | Benefit |

|---|---|---|

| Material Selection | Choosing the most cost-effective material that meets the project requirements. | Reduces material costs without compromising quality. |

| Design Simplification | Modifying designs to reduce complexity. | Lowers machining and tooling costs. |

| Volume Adjustment | Ordering optimal production volumes based on cost per unit analysis. | Exploits economies of scale for cost savings. |

| Utilizing Online Tools | Employing online calculators and DfM analysis for cost estimation. | Provides accurate cost estimations and identifies potential savings. |

By understanding and leveraging the components of pricing structures and the cost estimation process, customers can make informed decisions that optimize costs while achieving their manufacturing goals. Online manufacturing services offer a transparent and efficient way to navigate these complexities, ensuring a seamless experience from design to delivery.

Navigating Pricing Structures and Cost Estimation Process

Online manufacturing services typically use different pricing models, each with its own complexities. Fixed pricing is common, where a predetermined amount is established upfront, while variable pricing adjusts according to market conditions or complexity of the project. There’s also tiered pricing which varies according to the level of service required by the client. In order to navigate these pricing structures, customers need to have a clear understanding of their specific needs and expectations. To accurately estimate costs, factors such as design complexity, materials used, delivery timelines, among others need consideration. For instance, in tiered pricing model, if a customer requires a high-ended material for production with an expedited timeline, they will fall into a higher price category because both the material cost and urgency command premium charges.

Managing Intellectual Property Rights and Confidentiality in Online Manufacturing Services

Navigating through the complexities of online manufacturing services includes a major issue – managing intellectual property rights and maintaining confidentiality. This area holds considerable challenges and risks due to the potential for unauthorized access, theft, or misuse of proprietary information that’s inherent in the digital realm. Ensuring adequate protection often involves securing legal agreements that clearly define the ownership of intellectual property and outline penalties for infringement. It’s also prudent to execute Non-Disclosure Agreements (NDAs) with all parties involved, thus legally obliging them to maintain the secrecy of specific confidential information related to your product or process. Another protective strategy is adopting encrypted communication methods, which safeguard data transfers from interference while investing in robust cyber-security infrastructure will provide an additional layer of security. Navigating these measures effectively can prevent financial losses, reputational damage, and gives businesses the leverage to exploit their innovations fully.

Overcoming Language and Communication Barriers

In the age of international online manufacturing services, language barriers can present a sizable obstacle to effective communication. Effective strategies may include using translation software or hiring professional translators for critical information exchange. Regular training sessions could foster understanding of technical terms specific to the industry ensuring accurate interpretations. Just as valuable, is fostering a broader cultural understanding between parties which can significantly decrease miscommunication issues arising from differences in conversational norms or expectations. For instance, a casual business discussion might be interpreted differently across cultures; thus awareness helps promote clarity. Integrating these approaches can facilitate smoother orientations with foreign manufacturers, crucially aiding teams in navigating the complexities that often accompany global partnerships.

Quality Control and Assurance in Online Manufacturing Services

The efficacy and reputation of online manufacturing services is largely contingent on the stringency of their quality control and assurance measures. This critical aspect ensures that all products generated align with desired specifications and highest quality standards, thereby reinforcing customer satisfaction and trust. Various methodologies and technologies are employed towards this end, including automation, statistical process control, lean manufacturing, Six Sigma, and more. An example can be seen in leading providers like Protolabs or Fictiv, who use advanced, real-time inspection techniques combined with rigorous testing processes to maintain superior quality benchmarks throughout their manufacturing pipelines. In summary, meticulous quality control methods remain paramount in guaranteeing excellence and consistency within the sphere of online manufacturing.

Dealing with Shipping and Logistics Considerations

Navigating the logistics intricacies associated with shipping products from online manufacturers can present numerous challenges. These range from ensuring accurate fulfillment of orders to coordinating transportation schedules, dealing with international customs regulations if applicable, and managing potential delivery delays. To effectively handle these hurdles, implementing real-time shipment tracking systems can prove invaluable. Such platforms allow for continuous oversight over each product’s journey from the manufacturing factory floor right through to its final destination. Moreover, clear communication channels with both the manufacturer and the logistics provider will further facilitate timely deliveries, enabling action to be taken swiftly in case any shipping issues arise. For example, a company could employ automated alerts pertaining to shipment statuses so as to promptly mitigate any sudden changes or delays to ensure an efficient delivery flow.

Other Articles You Might Enjoy

- Navigating Excellence with CNC Machining Online Services in China

1. Introduction: The Digital Frontier of CNC Machining In this introductory section, we embark on a journey into the digital frontier of CNC machining, specifically focusing on the emergence and…

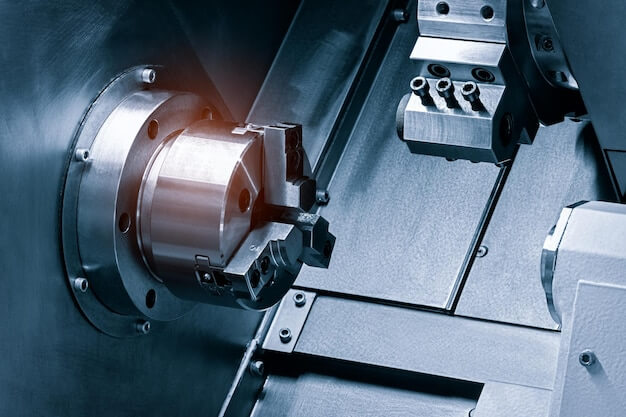

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…

- The Advantages of Using Molybdenum in CNC Machining Applications

CNC Machining Applications and the Role of Molybdenum Computer Numerical Control (CNC) machining is a revolutionary process transforming raw materials into intricate components. This cutting-edge approach automates control of machining…