Introduction

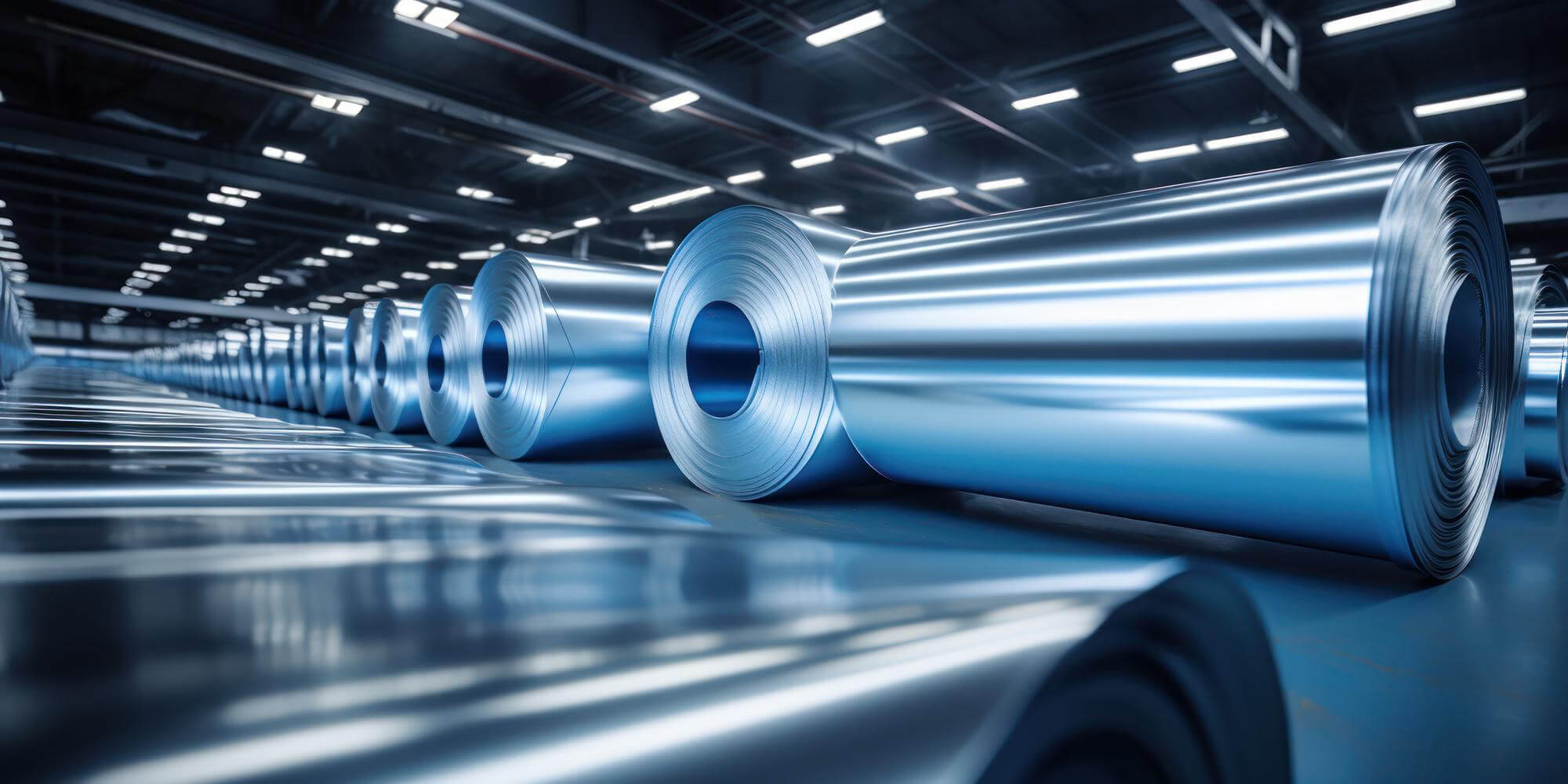

In today’s competitive manufacturing environment, efficiency and precision are key to meeting market demands. Custom aluminum sheet components play a critical role in many industries, from automotive to aerospace, electronics, and construction. However, optimizing the supply chain to meet custom specifications while ensuring cost-effectiveness and quick turnaround times can be challenging.

This is where CNC (Computer Numerical Control) technology comes into play. CNC machining allows for precise, customized aluminum sheet processing at scale, meeting the diverse needs of manufacturers while ensuring consistent quality.

In this article, we’ll explore how CNC machining can optimize your supply chain by improving efficiency, reducing costs, and delivering high-quality aluminum sheet components tailored to your exact needs.

Common Types and Applications of Aluminum Sheets

Different types of aluminum sheets are widely used in various industries. Each has specific characteristics that make it suitable for particular applications. Below are some of the most common aluminum sheet types and their uses:

| Aluminum Sheet Type | Key Properties | Common Applications |

|---|---|---|

| 3003 Aluminum | Excellent corrosion resistance, easy to work with | Roofing, chemical equipment, cooking utensils |

| 5052 Aluminum | Higher strength, good weldability | Marine applications, fuel tanks, pressure vessels |

| 6061 Aluminum | High strength-to-weight ratio, machinable | Aerospace components, automotive parts, structural applications |

Applications of Custom Aluminum Sheets

- Automotive Industry: Custom aluminum sheets are used to produce lightweight car body panels, engine components, and structural parts, helping manufacturers improve fuel efficiency and reduce emissions.

- Aerospace Industry: In aerospace, the strength-to-weight ratio of aluminum sheets is crucial for building durable yet lightweight components such as fuselage skins and wing parts.

- Construction and Architecture: Aluminum sheets provide weather resistance and aesthetic appeal in curtain walls, roofing, and facades, while CNC customization allows architects to achieve specific designs and shapes.

By understanding the various types and uses of aluminum sheets, businesses can make more informed decisions about which materials and machining processes will suit their needs best.

Why Choose CNC Machining for Aluminum Sheets?

Precision and Accuracy

CNC machining offers unparalleled precision, making it ideal for manufacturing custom aluminum sheet components that must meet strict tolerances. Using computer-aided design (CAD) models, CNC machines can cut, mill, and shape aluminum sheets with extreme accuracy, ensuring consistency across production runs.

Speed and Flexibility

With CNC machining, manufacturers can quickly shift between different designs, making it an efficient solution for both small-batch production and large-scale manufacturing. This flexibility is particularly useful for custom aluminum sheets that need to be modified based on client specifications or market demands.

Lower Production Costs

While CNC machining requires upfront setup, it becomes cost-effective for producing custom aluminum sheet parts, especially when compared to manual processes or traditional methods like stamping or molding. CNC machines reduce material waste and minimize human error, driving down long-term production costs.

How CNC Achieves High-Precision Aluminum Sheet Processing

CNC machining offers several key techniques for aluminum sheet fabrication, each with its advantages depending on the project’s needs.

| CNC Technique | Application | Advantages |

|---|---|---|

| CNC Milling | Precision cutting and shaping | High accuracy, suitable for complex geometries |

| CNC Laser Cutting | Cutting intricate patterns or designs | Clean edges, minimal material waste |

| CNC Drilling | Creating precise holes in aluminum sheets | Ideal for producing fasteners or attachment points |

| CNC Water Jet Cutting | Cold cutting method for thick aluminum sheets | No heat-affected zones, high precision |

Each of these techniques ensures high-quality outcomes with reduced turnaround times. By automating the process and relying on computer-aided instructions, CNC machines can deliver intricate designs that would be difficult or impossible with traditional methods.

Design and Material Selection for Custom Aluminum Sheets

When selecting aluminum sheets for CNC machining, it’s essential to consider the material properties required for the application. Different projects require different strengths, corrosion resistance levels, and weight considerations.

- Material Choice: For projects where corrosion resistance is critical (e.g., marine environments), 5052 aluminum would be a better choice than 3003 aluminum. On the other hand, 6061 aluminum offers superior strength and is ideal for structural or aerospace applications.

- Design Flexibility: CNC machining allows manufacturers to adjust design parameters quickly. Whether you need custom cut-outs, specific thicknesses, or detailed engraving, CNC machines can accommodate various design modifications with ease.

- Cost Considerations: The material and design choices directly influence the overall cost of the project. More complex designs or stronger aluminum grades (like 6061) may increase costs, but they provide the durability and performance necessary for high-stress applications.

Cost Analysis and Optimization Strategies for CNC-Machined Aluminum Sheets

Cost is a major consideration when deciding how to manufacture custom aluminum sheet components. Below are the primary factors affecting the cost of CNC machining aluminum sheets and some strategies to optimize these expenses:

Factors Affecting Costs

- Material Selection: Higher-grade aluminum (such as 6061) costs more than lower-grade options (like 3003), but it provides greater strength and durability for demanding applications.

- Design Complexity: More intricate designs require longer machining times, which can increase costs. Simple designs or batch production runs are generally more economical.

- Batch Size: Large production runs typically reduce the per-unit cost due to economies of scale. CNC machines are well-suited to handle both small and large batches, but large orders tend to result in lower costs per unit.

- Post-Processing: Additional processes such as heat treatment or surface finishing can increase costs but may be necessary to achieve the desired durability or appearance.

Cost Optimization Strategies

- Streamlined Design: Simplifying the design where possible can significantly reduce machining time and material waste, leading to lower overall costs.

- Batch Production: By consolidating similar orders or increasing batch sizes, manufacturers can maximize CNC machine efficiency, reducing the per-part cost.

- Material Efficiency: Selecting the appropriate material for the project ensures that you get the right balance of cost and performance, avoiding the expense of over-engineering.

| Cost Factor | Low-Cost Scenario | High-Cost Scenario |

|---|---|---|

| Material Choice | 3003 aluminum for basic applications | 6061 aluminum for high-strength requirements |

| Design Complexity | Simple geometries, standard dimensions | Intricate designs with complex features |

| Production Volume | Large batch production | Small batch or one-off prototypes |

| Post-Processing | Minimal surface finishing | Heat treatment and custom finishes |

These optimization strategies ensure that your aluminum sheet components are produced at the highest quality while maintaining cost efficiency.

Case Studies: CNC Technology in Custom Aluminum Sheet Applications

Case Study 1: Automotive Industry

A major automotive manufacturer required lightweight aluminum components for electric vehicle battery enclosures. By utilizing CNC laser cutting on 5052 aluminum sheets, the manufacturer was able to produce high-precision parts with minimal waste, reducing the vehicle’s overall weight while ensuring structural integrity.

Case Study 2: Aerospace Components

An aerospace company needed custom 6061 aluminum sheets for aircraft fuselage parts. CNC milling provided the necessary precision for tight tolerances, and post-machining treatments were applied to meet aerospace safety standards. This resulted in a 15% reduction in manufacturing costs and improved part performance.

FAQ

- What are the main benefits of using CNC for aluminum sheet processing?

- CNC allows for precise, consistent cutting, drilling, and shaping of aluminum sheets, ensuring high-quality results and enabling custom designs for various applications.

- How long does it take to machine custom aluminum sheets with CNC?

- The timeframe depends on the complexity and size of the project. Simple designs can be completed within hours, while larger or more intricate projects may take longer.

- Which types of aluminum sheets are best suited for CNC machining?

- Common types include 3003, 5052, and 6061 aluminum sheets. The choice depends on the specific application, as each type offers different properties like corrosion resistance and strength.

- Can CNC machines handle both small and large-scale production of aluminum sheets?

- Yes, CNC machines are highly versatile and can be used for both prototyping and mass production, depending on the project’s needs.

- What is the cost of CNC machining aluminum sheets?

- Costs vary depending on factors like material type, design complexity, and production volume. CNC machining is generally cost-effective for custom and high-precision work.

- How do I choose the right aluminum sheet for my project?

- The choice depends on factors such as the environment in which the sheet will be used, required strength, and corrosion resistance. Consulting with experts or CNC machinists can help in making the right decision.

- What industries commonly use CNC-machined aluminum sheets?

- CNC-machined aluminum sheets are used in industries like aerospace, automotive, construction, and electronics, where precision and customization are critical.

Other Articles You Might Enjoy

- CNC Machining Materials: Acrylic vs. Polycarbonate for Transparent Components

CNC Machining: An Introduction and the Importance of Material Type Computer Numerical Control (CNC) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and…

- Aluminum vs. Brass in CNC Machining: Determining the Best Metal for Your Precision Components

Introduction to CNC Machining and Precision Components CNC machining, an acronym for Computer Numerical Control machining, is a manufacturing process in which pre-programmed computer software dictates the movement of machinery.…

- Aluminum Grades: Key Characteristics and CNC Machining(Aluminum Grades and Properties Gemma)

As advancements in manufacturing technologies continue to evolve, industries are leveraging more efficient methods like CNC machining for their production processes. One of the commonly used materials in these operations…

- Understanding Aluminum Grades and Properties in CNC Machining (Aluminum Grades and Properties Lynn)

In the field of computer numerical control(CNC) machining, understanding aluminum grades, their properties, as well as how they influence the manufacturing process is vital. Aluminum, owing to its favorable properties…

- Custom Precision CNC Machining in Brass for Medical Devices

Custom Precision CNC Machining in Brass for Medical Devices Computer Numerical Control (CNC) machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine and cutting tools…

- Enhancing the Mechanical Properties of CNC Machined Parts through Material Blending

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated production of complex parts. This process relies on computerized…