Introduction to 3D Printing Filaments: PETG and PLA

At the heart of 3D printing technology lies an essential element known as filament, which is the thermoplastic feedstock for fused deposition modeling (FDM) printers. Amongst the plethora of materials available, two stand out for their popularity and versatility: Polyethylene Terephthalate Glycol-modified (PETG) and Polylactic Acid (PLA). These filaments are favored in different scenarios due to their unique properties– PETG offers enhanced durability and thermal resistance, whereas PLA is renowned for its ease of use and biodegradability. Hobbyists and professionals alike often deliberate between these options, weighing factors such as strength, flexibility, and environmental impact.

Definition and Characteristics of PETG

Polyethylene terephthalate glycol, more commonly known as PETG, is a thermoplastic polyester that offers significant chemical resistance, durability, and formability. It is recognized for its transparency and is often used in applications necessitating clarity, such as packaging. In 3D printing, PETG excels due to its ease of use: it adheres well to the print bed with less warping than other materials, has a relatively low shrinkage rate, and can be printed over a wide temperature range. Its flexibility, impact resistance, and glossy finish are characteristics that distinguish it from other filaments.

Advantages of Using PETG in 3D Printing

In the realm of 3D printing, PETG is favored for its blend of strength and ductility, which makes it ideal for creating durable parts with a high degree of toughness. Unlike some other materials, PETG does not absorb moisture easily, reducing the risk of degradation during storage and prolonging the filament’s usability. Furthermore, PETG’s ability to withstand higher temperatures without deforming excessively allows users to print objects for applications that may encounter warmer environments. Additionally, its compatibility with food-grade containers broadens its utility span, extending into both industrial applications and consumer products like water bottles.

Definition and Features of PLA

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane. This eco-friendly material stands out in the realm of 3D printing for its ease of use and low environmental impact. It prints at lower temperatures, typically around 180-220°C, with no need for a heated bed. Its main features include a glossy finish and minimal warping during cooling, which makes it ideal for a wide range of printing projects. Additionally, PLA emits a sweet smell when heated and does not produce harmful fumes, adding to its popularity among home users.

Benefits of Choosing PLA for 3D Printing Projects

Opting for PLA presents numerous advantages when undertaking 3D printing endeavors. Foremost, its user-friendliness makes it suitable for hobbyists and educators who require materials that are easy to print with and maintain dimensional accuracy. With its good tensile strength and surface quality, PLA is excellent for creating models, prototypes, and non-functional items. Moreover, the biocompatibility of PLA allows for applications in the medical field for short-term implants and scaffolds. The bio-based nature also renders PLA a responsible choice for environmentally conscious designers striving to minimize their carbon footprint while innovative pursuits flourish.

Physical Properties Comparison: Strength, Durability, and Temperature Resistance

In comparing the physical properties of PETG and PLA, distinct differences emerge that influence their applicability. PETG is renowned for its superior strength and durability over PLA, which makes it less prone to breakage under stress. This durability stems from PETG’s higher flexibility compared to the relatively brittle PLA; a characteristic that prevents cracks propagation. When it comes to temperature resistance, PETG again outperforms, maintaining structural integrity at higher temperatures where PLA might warp or deform. This feature makes PETG a better candidate for objects that will be subjected to heat or outdoor environments. On the other hand, PLA’s rigidity while being less durable can be advantageous for applications requiring precise tolerances, as it holds shapes well without flexing.

Printability and Ease of Use

In the realm of 3D printing, PETG and PLA exhibit distinct characteristics concerning printability and ease of use. PETG often demands a higher printing temperature ranging from 220 to 250°C, in contrast to PLA’s lower threshold of approximately 180 to 210°C, depending on brand-specific formulations. Regarding bed adhesion, PLA generally adheres well to a non-heated bed coated with blue painter’s tape or similar surfaces; however, PETG typically requires a heated bed near 70-90°C along with a surface treated with hairspray or glue stick to prevent warping. Precise printer settings are crucial for achieving optimal results: for instance, setting an appropriate retraction distance to combat stringing with PETG, whereas PLA benefits from proactive measures against heat creep by cooling during the process. While both materials have their own idiosyncrasiesmandating fine-tuning of individual printer settings, end-users find that PLA provides a more forgiving experience for starters, while PETG may demand additional adjustments but rewards with greater durability once dialed in correctly.

Safety and Environmental Impact of PETG vs. PLA Filaments

When considering the safety and environmental impact of 3D printing materials, fume emissions during printing are a significant factor. PETG is known to emit less noticeable odors compared to ABS but more than PLA when heated; however, scientific research on the health implications of these emissions remains inconclusive. PLA, being derived from renewable resources like cornstarch, releases a slightly sweet smell and is considered safer for indoor printing without extensive ventilation. In terms of biodegradability, PLA holds an advantage as it is compostable under industrial conditions, breaking down within several months, whereas PETG is recyclable but not biodegradable, requiring mechanical recycling processes to be reutilized effectively. Both types of filament contribute differently to environmental sustainability: PLA’s biodegradation reduces landfill mass over time, while PETG offers durability that can lead to reusable printed objects, theoretically minimizing waste through longevity.

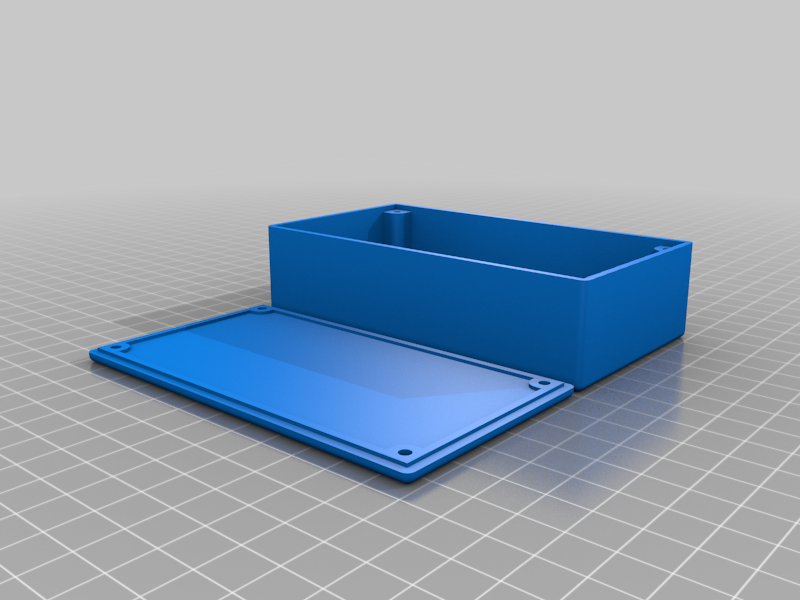

Applications and Use Cases of PETG and PLA

PETG, valued for its durability and flexibility, often finds application in practical scenarios that demand a material with impact resistance and thermal stability. Common uses include manufacturing containers, mechanical parts, and items requiring sterilization, making it a mainstay in medical device production and food packaging industries. On the other hand, PLA excels in ideal situations that prioritize biodegradability and ease of use, such as prototyping, hobbyist modeling, and educational tools where environmental friendliness is equally important. For example, if one needed to print a durable water bottle, PETG would be the preferred choice due to its toughness and water-resistance, while PLA would be more suitable for creating a biodegradable planter, where its eco-friendliness and adequate structural integrity are key factors.

Cost Factor

When comparing the cost of PETG to PLA, it’s crucial to consider both initial price points and long-term cost-effectiveness for specific applications. Typically, PETG commands a higher upfront cost relative to PLA due to its enhanced performance attributes such as improved durability and thermal resistance. However, the investment in PETG can often be justified over time, especially for parts that are expected to endure more stress or require higher heat tolerance. In contrast, while PLA is generally less expensive and may offer sufficient performance for prototyping or non-functional objects, its lower resistance to heat and weaker structural integrity could lead to more frequent part replacement in practical applications. Therefore, users should weigh the nature of their project’s requirements against these materials’ characteristics to make an informed decision on the most cost-effective choice.

Q&A Section: Suitability and Usage of PETG vs. PLA

PETG-printed objects are best suited for environments that demand higher durability and flexibility, as well as resistance to temperature fluctuations and chemical exposure; this makes them ideal for both indoor and outdoor applications where sturdiness is required. Conversely, while PLA can be used outdoors, it degrades over time due to UV exposure and is not recommended for long-term external use without additional protections such as UV-resistant coatings. When comparing print speeds, typically, PLA can be printed at faster rates than PETG due to its lower melting temperature and ease of adhesion. However, a heated bed is only essential for PETG to prevent warping given its high shrinkage rate upon cooling, whereas PLA’s low-warp characteristics often allow printing with or without a heated bed, though using one could still improve adherence and overall print quality.

Other Articles You Might Enjoy

- 3D Printing Filaments: PLA vs. PETG - What You Need to Know

Introduction to 3D Printing Filaments: PLA and PETG In the expansive realm of 3D printing, filaments form the backbone of every successful print. Simplistically put, a 3D printing filament is…

- 3D Printing Filaments: PLA vs. PETG - What You Need to Know

Introduction to 3D Printing and Filament Types The advent of 3D printing has revolutionized various industries, enabling the production of complex parts with unprecedented precision. This innovative technology works by…

- Galvanized vs. Galvanneal: What Are the Differences?

In the realm of metal finishing and corrosion protection, two processes often come up: galvanizing and galvannealing. Both methods enhance the durability and longevity of steel and other metal products,…