Introduction to Plastics Extrusion Technology

Plastics extrusion is a high-volume manufacturing process in which raw plastic material, often in the form of pellets or granules, is melted and formed into a continuous profile through a die and shaped into various products. The technology has evolved from its rudimentary inception in the late 19th century, when it was first used to produce lead pipes, to today’s sophisticated methods that create complex plastic shapes for a multitude of applications. Its history is marked by innovations such as the development of thermoplastics during the early 20th century, broadening the variety of products amenable to extrusion. The key principles underlying this transformative technique include the feeding of polymer material to an extruder, where it undergoes heating, melting, and pressurization before being forced through a shaping tool—culminating in rapid cooling to retain the designed configuration.

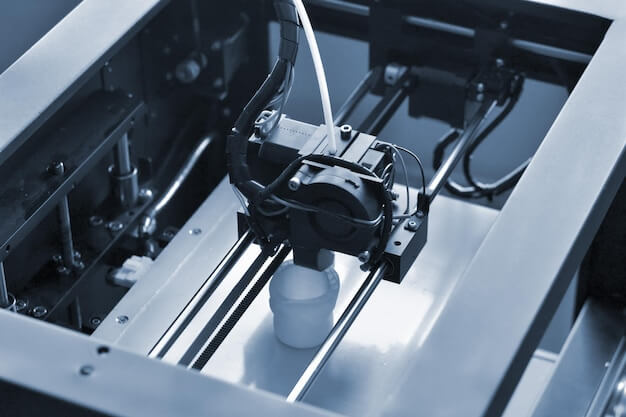

Principles of Plastic Extrusion

The plastic extrusion process encompasses the continuous conversion of raw plastic material into a consistent cross-sectional profile, achieved through an apparatus known as the extruder machine. This complex equipment typically consists of several core components: the hopper for introducing the raw plastics; the feed throat where materials enter the barrel; the screw mechanism inside the barrel which propels and thoroughly mixes the molten plastic; the heater which raises the temperature to carefully controlled levels; a die that molds the material to the desired shape; and finally, a cooling system that solidifies the shaped output. The sequence commences by loading polymer pellets or powder into the hopper, passing them down to the barrel where they are carried forward by the rotating screw, melting due to heat and shear forces. Upon reaching homogeneity, the viscous liquid is pressed against the contours of the die, causing it to adopt a specific geometrical outline. As it exits, the profile undergoes cooling—typically via air or water—to harden into its ultimate form.

Key Benefits of Using Plastic Extrusion Technology

The efficiency in mass production afforded by plastic extrusion technology stands as one of its primary advantages. This streamlined process allows for the continuous creation of plastic products, minimizing interruptions and maximizing output, making it an ideal solution for high-volume manufacturing requirements. Furthermore, versatility is inherent to the technology; it can produce a myriad of shapes and sizes ranging from simple tubing to complex profiles tailored to specific industry needs. Additionally, energy savings are realized through the nature of continuous processing, which reduces the need for repetitive heating and cooling cycles typically associated with batch production methods. The combined effect of these benefits underscores the pivotal role plastic extrusion plays in modern manufacturing.

Broad Applications of Plastic Extrusion

Plastic extrusion technology has diversified into various industries owing to its versatile application spectrum. In the packaging industry, it facilitates the creation of multi-layered materials that ensure product integrity and prolonged shelf life. Within construction, extruded plastics are crucial for producing robust piping systems and structural profiles resistant to weathering and corrosion. The automotive sector employs this technology extensively for the economical manufacturing of durable parts like bumpers, dashboards, and fluid conduits. Moreover, in textile engineering, plastic extrusion is pivotal for fabricating sheets, films, and fibers which are then transformed into a myriad of consumer goods ranging from breathable protective clothing to lightweight luggage.

Innovations in Plastic Extrusion Technology

The field of plastics extrusion technology is witnessing significant innovations, particularly with developments in materials and machinery enhancements. On the materials front, bioplastics are gaining attention for their potential to mitigate environmental impact; these polymers can be derived from renewable resources and offer improved biodegradability. Additionally, advancements have been made in creating highly recyclable polymers that maintain physical properties post-recycling, thus promoting a circular economy. In terms of machinery, the introduction of precision controls has revolutionized extrusion processes by ensuring consistent product quality and reducing material waste. Automation plays a pivotal role as well, boosting efficiency through integrated systems capable of intricate monitoring and adjustments during production. These technological progresses contribute to both ecological sustainability and economic viability within the plastic extrusion industry.

Environmental Impact and Sustainability Considerations

In the realm of plastics extrusion technology, environmental impact and sustainability considerations have become increasingly pivotal. The industry is shifting towards more eco-friendly practices to mitigate issues associated with plastic waste. Central to this transformation is the enhancement of recycling processes for extruded products. By refining the techniques used to reclaim polymers from extruded materials, manufacturers can minimize waste and facilitate a circular economy where plastics are continuously repurposed. Furthermore, there’s a growing adoption of biodegradable or bio-based resins that inherently offer a reduced environmental footprint. These trends underscore a commitment within the industry to address environmental concerns and promote sustainability throughout the life cycle of extruded plastic products.

Case Studies of Extrusion Technology in Industry

A notable instance of successful extrusion technology deployment can be observed in the case of a prominent automotive parts manufacturer. By incorporating advanced extrusion techniques, the company has significantly enhanced the structural integrity and uniformity of their polymer-based components, which are pivotal in vehicle weight reduction efforts. Diving into the technicalities, this involved precision control over the cooling rates post-extrusion and refined screw designs to ensure consistent melt flow. This meticulous process yielded high-performance parts with improved dimensional stability and surface finish, translating into better fuel efficiency without compromising safety or aesthetics. Consequently, such advancements have streamlined production processes, reducing material wastage and energy consumption, thereby mirroring both economic and environmental benefits.

Common Challenges in Plastics Extrusion Process

In the plastics extrusion process, various challenges can arise that technicians have to address to maintain product quality and operational efficiency. A primary issue faced during extrusion is achieving consistent material properties; variations in resin characteristics or feedstock purity can affect the final product’s structural integrity and performance. Another significant challenge involves die design – creating a die that precisely shapes the molten plastic without causing irregularities requires expert engineering and careful consideration of flow dynamics. Moreover, maintaining optimal temperatures throughout the extrusion barrel is critical to prevent material degradation or uneven melting, which could result in defects such as warping or surface imperfections in the extruded product.

Compatibility of Plastics with Extrusion Technology

Extrusion technology, a versatile manufacturing process, is not universally compatible with all plastics due to the varying thermal and rheological properties inherent to different polymer families. Thermoplastics such as polyethylene (PE), polypropylene (PP), and polystyrene (PS) are commonly extruded given their ability to be melted and formed repeatedly. These materials exhibit high flow under heat, making them suitable for continuous production of films, tubes, and profiles. In contrast, thermosetting plastics require special attention since they cannot be re-melted once cured; thus, their use in extrusion is limited and often involves pre-processing into a partially cured state before forming. Engineering plastics like polyamide (PA) and acrylonitrile butadiene styrene (ABS) may also be used, offering higher strength and temperature resistance, though they sometimes need specific screw designs and processing conditions to address challenges such as moisture content or thermal degradation during extrusion.

Evolution of Extrusion Technology in Reducing Environmental Impact

Sustainable practices and material innovations have been at the forefront of extrusion technology’s evolution as it adapts to reduce environmental impact. Advances include the development of biodegradable polymers that facilitate easier recycling and composting, thus lessening plastic waste accumulation. Furthermore, incorporation of energy-efficient machinery reduces carbon footprints by consuming less power during the extrusion process. Precision control systems are now used to minimize raw material wastage, ensuring that each run is optimally efficient. Companies also aim for closed-loop water systems to diminish water usage and contamination. By integrating these sustainable practices, extrusion technology demonstrates a commitment to eco-friendly production processes while maintaining the high-quality output essential to broad industrial applications.

Benefits of Investing in Advanced Extrusion Equipment for Businesses

Businesses that invest in advanced extrusion equipment can realize significant benefits, including cost savings, product quality improvements, and increased production rates. Advanced machinery often comes with more precise control systems, enhancing material throughput and reducing waste through tighter tolerances and less material variance. For example, modern extruders might integrate real-time monitoring that adjusts parameters instantly for optimum efficiency, leading to substantial reductions in raw material costs. Improved product quality is achieved via enhanced stability in the extrusion process, which ensures consistent shape, thickness, and structural integrity, thereby meeting higher standards demanded by customers. Increased production rates are facilitated by faster-operating speeds and quicker changeover times between runs, enabling businesses to meet market demands promptly while optimizing labor costs.

Other Articles You Might Enjoy

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a high-precision manufacturing process used in producing miniature and intricate plastic parts. This procedure, employing specialised machines with high-pressure moulding capabilities…

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with precision. The process involves injecting…

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is an advanced manufacturing technique that miniaturizes traditional injection molding processes. The principle of micro injection molding revolves around producing tiny, intricate…