Machining precision is the foundation for ensuring the performance and longevity of mechanical products. During machining, various factors can cause the correct position between the tool and the workpiece to shift, resulting in parts that do not fully meet ideal specifications. The indicators for measuring machining quality include precision and surface quality. This chapter discusses issues related to machining precision.

Machining Precision and Errors

In machining, the degree to which the actual geometric parameters (dimensions, shape, and position) of a part match the ideal geometric parameters is called machining precision. The deviation between these parameters is known as machining error. High precision means low error, and vice versa. National tolerance standards specify the levels of machining precision. Ensuring and improving precision essentially means limiting and reducing errors.

Three Aspects of Precision

- Dimensional Precision: The degree to which actual dimensions match the design dimensions.

- Shape Precision: The degree to which actual shapes match the design shapes.

- Positional Precision: The degree to which actual positions match the design positions.

When high dimensional precision is required, corresponding shape and positional precision are also required. However, high shape precision does not necessarily mean high positional and dimensional precision.

Relationship Between Precision, Cost, and Efficiency

Generally, higher precision requirements lead to higher costs and lower production efficiency. Therefore, in actual production, a balance must be found between precision, cost, and efficiency.

Factors Affecting Machining Precision

Machining precision is influenced by multiple factors, which can be categorized as follows:

- Original Errors: Including errors from the machine tool, fixtures, tools, and workpieces. These are referred to as original errors in the machining system.

- Errors During the Machining Process: Including adjustment errors, clamping errors, machining errors, and measurement errors.

- Environmental Factors: Such as temperature changes and vibrations, which also affect machining precision.

Sources of Original Errors

- Machine Tool Errors: Including guideway errors, spindle rotation errors, and transmission chain errors.

- Fixture Errors: Including manufacturing errors, assembly errors, and wear of fixtures.

- Tool Errors: Including manufacturing errors and wear of tools.

Impact of Machine Tool Errors

Machine tool errors are a major factor affecting the machining precision of workpieces. Errors in the machine tool guideways, spindle rotation, and transmission chains can all cause machining errors.

Guideway Errors

Machine tool guideway errors include straightness errors in the horizontal and vertical planes and parallelism errors between guideway surfaces. These errors can result in shape errors in the machined workpieces.

Spindle Rotation Errors

Spindle rotation errors refer to the variations in the spindle’s actual rotation axis relative to its average rotation axis during operation. These errors affect the roundness and cylindricity of the workpieces.

Methods to Improve and Ensure Machining Precision

To improve and ensure machining precision, various measures can be taken, including:

- Reducing Original Errors: Improving the manufacturing precision of machine tools, fixtures, and tools, and reducing assembly errors and wear.

- Controlling Environmental Factors: Controlling temperature, vibrations, and other environmental factors that affect precision.

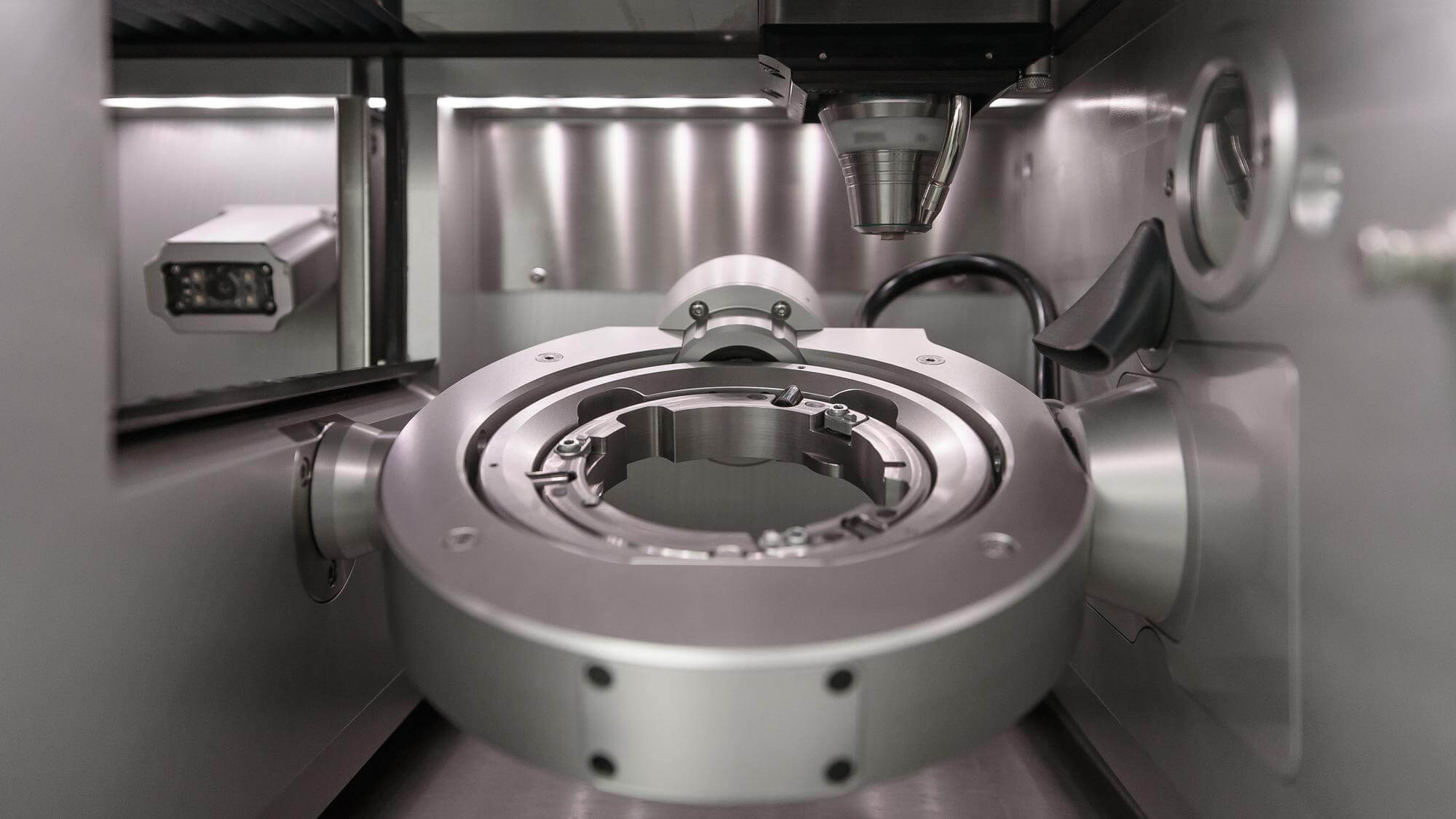

- Using Advanced Machining Processes and Equipment: Utilizing high-precision CNC machines and advanced machining processes such as error compensation techniques.

Error Compensation Techniques

Error compensation involves artificially creating a new original error to offset the inherent error in the machining system, thereby reducing machining errors and improving precision. Modern machining widely uses techniques such as automatic tracking measurement and automatic compensation to achieve high-precision machining.

Example Data Table

Below is a simple data table illustrating the relationship between machining precision, cost, and efficiency:

| Precision Level | Cost (CNY) | Production Efficiency (pcs/hour) |

|---|---|---|

| Rough Machining | 100 | 20 |

| Medium Precision | 200 | 15 |

| High Precision | 400 | 10 |

| Ultra High Precision | 800 | 5 |

As shown in the table, higher precision leads to higher costs and lower production efficiency.

Machining precision is crucial for ensuring the performance and longevity of mechanical products. By understanding the various factors affecting precision and taking appropriate control measures, we can improve and ensure machining precision, thus producing high-quality mechanical parts. I hope this chapter provides some valuable insights for your practical production needs. If you have any questions, feel free to discuss them anytime!

Other Articles You Might Enjoy

- Machining Precision and Its Control

In machining, controlling precision is a crucial aspect that directly affects the quality and performance of the final product. This chapter details the factors influencing machining errors, geometric errors of…

- Control of Machining Precision

Machining precision refers to the degree to which the actual geometric parameters of a machined part conform to the ideal geometric parameters (such as size, shape, and positional relationships). Improving…

- High-Precision CNC Machining for Military Applications

Introduction to High-Precision CNC Machining in Military Applications The technical realm of high-precision Computer Numeric Control (CNC) machining is fast becoming integral to the military sector. This process, which relies…

- Precision Machining with Tool Offsets for CNC Lathe Parts

When it comes to CNC machining, precision is key. Achieving high precision in CNC lathe parts requires a deep understanding of tool offsets and their functions. Let's dive into the…

- Tool compensation in CNC machining, our quest for precision in CNC machining

Introduction to CNC Machining and Precision CNC (Computer Numerical Control) machining stands at the forefront of modern manufacturing, utilizing computerized controls to operate complex machinery with remarkable accuracy. This process…

- Precision CNC Machining for High-End Audio Equipment

Precision CNC Machining and its Role in High-End Audio Equipment Manufacturing The production of high-end audio equipment relies heavily on precision-driven processes to ensure the best quality sound. One such…