Introduction: Precision CNC Machining and the Use of Stainless Steel

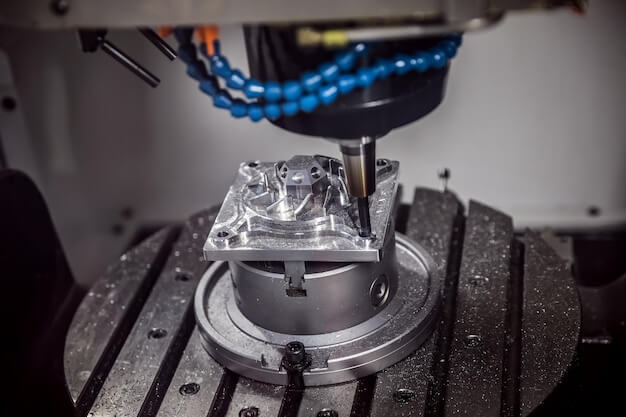

Precision Computer Numerical Control (CNC) machining, a vital technology within the manufacturing industry, uses pre-programmed software to guide machinery towards the production of complex 3D parts with precision. This innovative technique plays an instrumental role in numerous industries, such as aerospace, automotive, and medical equipment manufacturing, where intricate designing and high accuracy are required.

Despite being able to process various materials, stainless steel remains a top choice in CNC machining because of its favorable properties. Its excellent resistance against corrosion, coupled with superior heat tolerance, makes it particularly advantageous within the demanding conditions of the aerospace sector. Beyond these benefits, stainless steel’s inherent strength can withstand extreme pressure or heavy loads which are typical aviation parameters.

- The versatility of CNC machining allows for processing various materials, however, stainless steel is often preferred due to its beneficial attributes.

- In the harsh conditions of the aerospace field, stainless steel provides unbeatable resilience to corrosion and heat.

- Furthermore, the robust nature of stainless steel gives manufacturers confidence that machines will bear immense beyond duty cycle stresses encountered in space exploration.

Technological Advances in Precision CNC Machining

Technological advances have revolutionized precision CNC machining, enhancing the capabilities of producing intricate and high-quality components. These advances have led to improved efficiency, accuracy, and speed in the manufacturing process, ensuring that the aerospace industry can meet its demanding requirements.

Best Practices in Aerospace Machining

In the field of aerospace machining, adhering to best practices plays a crucial role not just in ensuring optimum efficiency but also maintaining the integrity and safety of produced parts. These guidelines are typically shaped by myriad factors such as technological innovations, industry standards, and governmental regulations.

A cardinal element among these practices is proper equipment maintenance. A well-maintained machine invariably improves performance, guarantees precision, extends longevity, minimizes downtime, and more importantly, ensures the production of accurate aerospace components. Moreover, leveraging state-of-the-art software tools — like CAM (Computer-Aided Manufacturing) systems that streamline manufacturing processes or CAD (Computer-Aided Design) applications for precise designing — has fast become an indispensable best practice in this sector.

To illustrate further, let’s look at Lockheed Martin – one of the world’s leading aerospace manufacturers. The company religiously follows stringent equipment maintenance schedules and utilizes advanced software tools to keep up with the rapidly-changing technology landscape. As a result, they constantly deliver innovative, high-quality components while concurrently driving down costs and reducing lead times. Thus, Lockheed serves as a sterling example of how implementing these best practices can be instrumental to achieving success in the aerospace machining realm.

Importance of Precision CNC Machining in The Aerospace Industry

In the aerospace industry, the significance of high-precision CNC machining cannot be overstated. Every component that forms part of an aircraft must meet exact specifications to ensure proper function and safety. Notably, a tiny error or deviation while creating these parts can lead to disastrous consequences for overall aircraft performance and passenger safety.

- Machining errors may result in complications such as parts misalignment, structural weakness, or even system failure.

- For instance, during the manufacturing process, any inaccuracies in drilling holes for bolt fasteners can compromise the integrity of the entire assembly, potentially triggering significant issues mid-flight.

A prime example illustrating this peril occurred in 2002 when a lack of precision in machining led to the crash of China Airlines Flight 611. Improperly repaired damages to the plane’s fuselage resulted from slight machining deviations – these culminated in catastrophic mechanical failure. This incident emphasizes both the need for absolute precision in aerospace component machining and the grave risks associated with even minute imperfections. Consequently, precision CNC machining remains integral to the production of reliable, durable, and safe aerospace parts.

Conclusion

Innovation and best practices in precision CNC machining have transformed the aerospace industry, enhancing efficiency, accuracy, and productivity. Advancements such as high-speed machining and multi-axis machines allow for the production of complex parts with tighter tolerances. Using advanced software provides better control over tool paths, improving the finished product’s quality.

- The increasing use of stainless steel in aircraft design underscores the importance of precise and efficient methods of working with this material.

- Best practices in Precision CNC Machining focus on reducing errors, minimizing waste and adhering to rigorous safety protocols.

- The continuous development of machining technology promises further improvements, potentially revolutionizing manufacturing processes within the aerospace sector.

Looking ahead, there is vast potential for the integration of artificial intelligence and data analytics in Precision CNC Machining, enhancing predictive maintenance capability and capacity planning. As these technological shifts occur, it is crucial that industry professionals continually update their knowledge and techniques to remain competitive. The evolution of Precision CNC Machining presents a compelling opportunity for future growth and efficiencies within the aerospace industry.

Other Articles You Might Enjoy

- Stainless Steel Machining for Aerospace: Precision and Challenges in CNC Operations?

Introduction: Brief Overview of CNC Machining and Its Importance in the Aerospace Industry Computer Numerical Control (CNC) machining is a modern manufacturing process using pre-programmed computer software to control movement…

- Aerospace CNC Machining: Precision Engineering for the Skies

CNC (Computer Numerical Control) machining stands as a cornerstone in the production of aerospace components, where its application spells the difference between success and catastrophic failure. In an industry that…

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining: The Role of Stainless Steel and Aluminum Computer Numerical Control (CNC) machining is a groundbreaking method in manufacturing that involves precise computer commands to manipulate and control tools…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…

- Stainless Steel Machining for Aerospace: Precision and Challenges in CNC Operations?

Introduction: Brief Overview of CNC Machining and Its Importance in the Aerospace Industry Computer Numerical Control (CNC) machining is a modern manufacturing process using pre-programmed computer software to control movement…