Our world is surrounded by rapidly advancing complex technologies. In our daily lives, we see many intricate parts, such as gears and internal components of machines, which make us wonder what it takes to manufacture them. The answer is often the same: CNC precision machining.

Computer Numerical Control (CNC) processes are the cornerstone of modern industry, automating the production of parts at unimaginable speeds. CNC precision machining goes further, improving accuracy and simplifying the manufacturing process. This article will discuss precision machining, how it is done, the tools required, and more.

What is Precision Machining?

Precision machining is a manufacturing process that uses computer-controlled machine tools to produce parts. It is a high-speed machining process used to manufacture parts that require tight tolerances, high complexity, or both. Precision machining can be performed by skilled machinist operators or high-speed robots. It is a subtractive manufacturing process where the machine starts with blocks of material and removes material using cutting tools. Precision machining is typically used to create various parts that fit and work together.

Basic Steps of Precision Machining

Designing the Graphical Model

Creating any part requires a graphical model, achieved through Computer-Aided Design (CAD) software. CAD software allows designers to create 2D and 3D models of any part for manufacturing. The design usually starts with hand-drawn sketches to understand the basic concept of the part. Then, CAD designers reference these sketches to create dimensionally accurate graphical models.

Converting CAD to CAM

CAD creates a graphical representation of parts in digital format. This representation is easy for designers, operators, and manufacturers to understand, but CNC machines cannot directly interpret this digital format. Machines understand coordinates to move cutting tools or workpieces. Therefore, CNC machines require part designs in a suitable format to provide necessary manufacturing instructions. Computer-Aided Manufacturing (CAM) software is used to create a readable format for CNC machining.

Machine Setup

Once the design is ready in CAM format, it’s time to set up the machine. This typically involves calibrating the machine tool and mounting the workpiece on the machine. The machine tool can vary based on the workpiece material and the final part’s design. In this step, it’s important to tighten all clamps properly and ensure acceptable machine parameters (such as coolant levels).

Executing the Machining

After setup, the machine program can be executed. Most CNC machines have displays to monitor the program and adjust various parameters. Once the program is executed, the CNC machine will start the precision machining process.

Finishing

After manufacturing parts with precision machines, they can be removed. Depending on the requirements, parts may be sent for secondary processing, such as grinding or polishing. However, in most cases, parts made with precision machining do not require any secondary processing.

Methods and Equipment of Precision Machining

Due to the wide range of applications for precision machining, there are many types of machines and equipment for precision machining. Different parts require different types of cutting, leading to the development of a range of cutting tools.

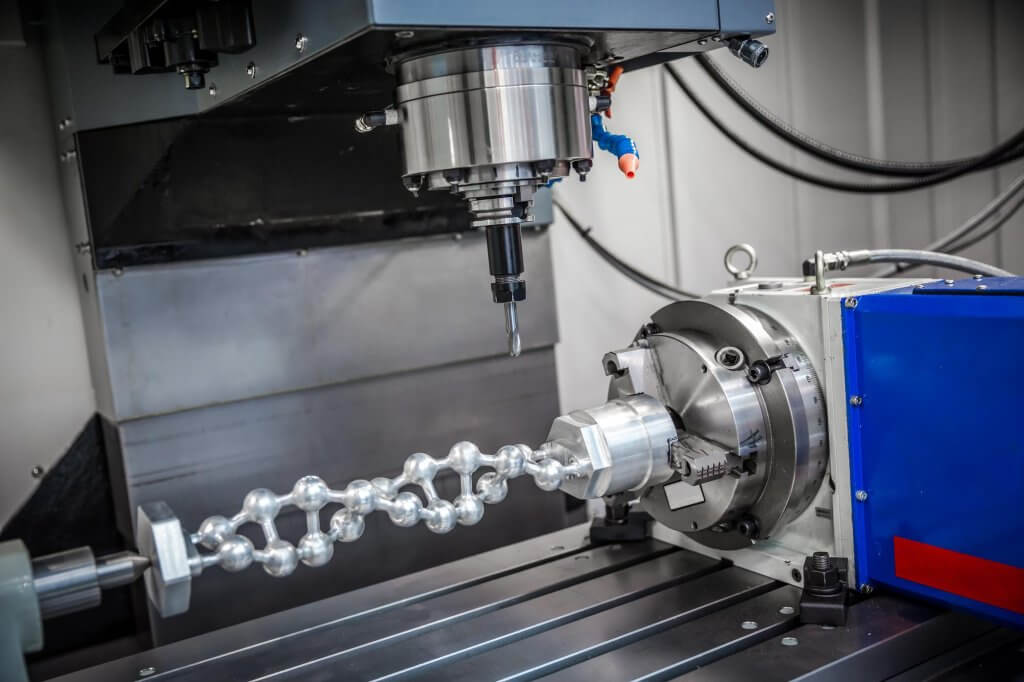

CNC Milling Machines

CNC milling is a subtractive manufacturing process that uses rotating cutting tools to remove material from the workpiece. The direction, angle, pressure, and speed of the cutting tool can vary to produce different cutting effects.

CNC Turning

In CNC turning, the workpiece rotates along a central axis, and a linearly moving cutting tool removes material from the workpiece. Unlike CNC milling, the cutting tool is usually non-rotating.

Precision Grinding Machines

Precision grinding machines are one of the final manufacturing processes for machining parts. In precision grinding, an abrasive grinder (or grinding wheel) forms a very flat surface on the machined part, resulting in a very smooth surface.

CNC Drilling Machines

In CNC drilling machines, the workpiece remains stationary while a rotating drill bit moves around to create holes in the workpiece. CNC drilling machines can create holes of different sizes by changing the drill bit.

Multi-Axis CNC Machining

Multi-axis CNC machining is a comprehensive machining system where cutting tools can move in four or more directions. Multi-axis CNC machining can use various cutting tools and processes (such as milling, water jet cutting, or laser cutting) to manufacture complex parts.

Electrical Discharge Machining (EDM)

In Electrical Discharge Machining (EDM), metal is shaped using electrical sparks. EDM only works on metals because they conduct electricity. It uses two electrodes – a tool electrode and a workpiece electrode.

Benefits of Precision Machining

Strict Tolerances

Strict tolerances are a major reason for using CNC precision machining. Tolerance, also known as dimensional accuracy, refers to the small deviations between the machined part’s dimensions and its CAD blueprint. CNC precision machining uses specialized processes and cutting tools to minimize tolerances.

High Accuracy

Strict tolerances directly mean that the final product of precision machining will have high accuracy. Precision machining is often used for parts that need to interact with other parts and components.

High Repeatability

The concept of repeatability is one of the important foundations of modern manufacturing. Every part manufactured through a process is intended to look exactly like the other parts to the end user. Any deviation from this replication is usually considered a defect. Precision machining is attractive in this regard.

Low Production Costs

Since precision machining has no deviations, there are fewer production defects. This reduces the rejection rate of parts and material costs. Additionally, as an automated computer-aided manufacturing process, it reduces labor costs.

Speed and Efficiency

Precision machining involves high-speed robots that can manufacture parts faster than manual manufacturing on traditional lathes. Additionally, parts have high accuracy and tight tolerances, so no secondary processing is required. This shortens production time and improves productivity and efficiency in the workshop.

Safety

CNC machines replace human labor with computer-controlled systems, eliminating the risk factors of human error during cutting. Workers can shift to technical-intensive jobs like CNC design operations.

Materials Suitable for Precision Machining

Precision machining is suitable for hundreds of different metals, plastics, and other composites. Below is a list of some common materials processed by precision machining:

| Material | Characteristics | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Automotive parts, aircraft components |

| Stainless Steel | High corrosion resistance, excellent mechanical properties | Food industry, medical equipment, marine applications |

| Brass | Good corrosion resistance, excellent machinability | Plumbing fittings, electrical connectors, decorative items |

| Copper | Excellent conductivity and thermal properties | Wiring, heat exchangers, roofing |

| Bronze | Strong, corrosion-resistant | Bushings, bearings, coins, marine hardware |

| Titanium | Lightweight, strong, corrosion-resistant | Aerospace structures, medical implants |

| Polycarbonate (PC) | Impact-resistant, transparent | Safety equipment, optical lenses, electronic enclosures |

| ABS | High strength, good toughness, heat resistance | Automotive parts, consumer goods, electronic components |

| POM (Polyoxymethylene) | High rigidity, low friction, wear-resistant | Precision gears, bearings, electrical engineering components |

| Glass | High hardness, good transparency | Optical equipment, decorative items, building materials |

| Graphite | Good conductivity, high-temperature resistance | Batteries, electrodes, lubricants |

Applications of Precision Machining

Precision machining is fundamental in many industries, whether for processing tools or manufacturing final products. Here are some application areas:

Prototyping

Precision machining is used to create prototypes for all industries. Prototypes need to accurately reproduce the intended design to portray product features.

Automotive Industry

The automotive industry requires complex gears and engine components, axles, nuts, and other parts. These parts for motorcycles, cars, trucks, ships, and aircraft are manufactured using precision machining tools.

Medical Industry

Medical technology is becoming increasingly complex. There are automated tools and devices in the medical industry that can even perform surgeries. These devices require complex machining on a microscopic level, which precision machining makes possible.

Aerospace

The aerospace industry uses some of the most advanced equipment, materials, and technologies. It requires a machining process that is not only highly accurate but also capable of handling the toughest materials. Precision machining provides a simple solution for manufacturing various parts in the aerospace industry, from prototypes to full-sized components.

Defense Industry

The defense industry’s requirements are similar to those of the aerospace industry. It needs the toughest materials and high-quality precision machining. Applications range from new weapon prototypes to entire missile systems.

Conclusion

Precision machining has become an indispensable part of modern industry. Through a manufacturing process of high precision, efficiency, and repeatability, precision machining makes the production of complex parts more reliable and economical. In manufacturing, from automotive parts to medical devices to aerospace components, precision machining plays a critical role, providing high-quality solutions for various industries.

Other Articles You Might Enjoy

- Introduction to Precision Parts Machining: Cutting and Special Processes

Precision parts cutting machining primarily includes precision turning, mirror grinding, and lapping. Using finely ground single-crystal diamond tools on precision lathes, ultra-fine turning is performed with a cutting thickness of…

- Precision 5-Axis CNC Machining in the Automotive Industry

The automotive industry is an integral part of our daily lives, shaping our work commutes and leisure activities. Within this industry, CNC automotive technology plays a pivotal role, transforming the…

- Custom Precision CNC Machining Services for Bronze Parts

Introduction to CNC machining and Bronze Parts Manufacturing Custom precision Computer Numerical Control (CNC) machining is a unique technology that employs computerized controls and machine tools to eradicate layers of…

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Precision and Control in Machining

Machining precision is the foundation for ensuring the performance and longevity of mechanical products. During machining, various factors can cause the correct position between the tool and the workpiece to…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…