The emergence of CNC machining has changed the entire manufacturing industry. This technology has been developed for more than 70 years and is now very mature. And used in various industries, such as automobiles, aerospace, medical device manufacturing, etc.

Prototype CNC machining is one area where this technology has proven advantages. CNC machining prototyping solutions are indispensable for every industry when applying CNC processes. As a result, many manufacturers are wondering: What is the best way to prototype CNC machining parts?

In this article, we will give you a comprehensive introduction to CNC machining prototypes, including how to create them, their advantages and disadvantages, and why it is important.

What is prototype CNC machining?

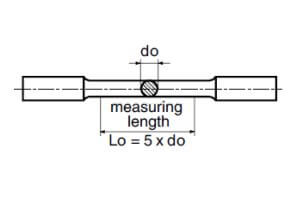

Prototyping is the process of quickly creating prototypes of parts using CNC machines. Typically produced in smaller batches in order to provide a visual and functional representation of the final product. In short, prototyping determines the final result of digital design.

Through prototyping, manufacturers can more intuitively see defects in part designs. So that these defects can be eliminated before mass production, thereby saving trial and error costs and increasing profits.

Why is CNC machining important to prototype processes?

Maybe you didn’t know the importance and benefits of CNC machining prototypes until now. But you will find that whenever a prototype machining process is required, CNC machining is always the first of choice.

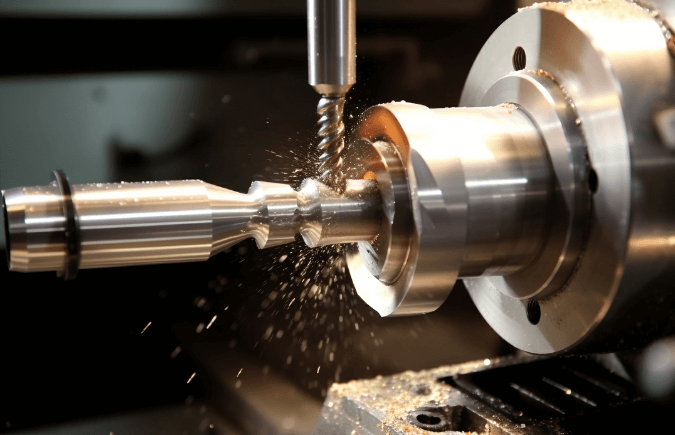

CNC technology uses computers to control and monitor the movement of the cutting head and workpiece. This movement can be controlled within the most minor intervals, making it nearly impossible to replace the prototyping process.

CNC prototyping machining begins by creating a 3D CAM model of the final product. After the model is completed, a CAD file is generated. The CNC machine tool directly understands the CAD file because it contains instructions on how the machine should do.

CAD files can be converted into CAM files containing G-code and M-code. G code controls movement, while M code involves general operation control of CNC machine tools, such as coolant operation.

Advantages and limitations of prototype CNC machining

When you are choosing whether to use CNC machining prototypes, you need to consider the advantages and limitations of prototype CNC machining. This way, you can get the most out of your CNC prototyping as needed.

Advantages of prototype CNC machining

CNC prototyping offers these advantages:

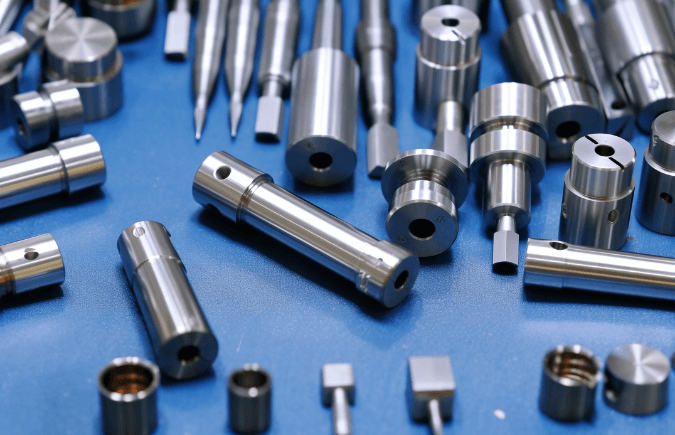

- Repeatability and Consistency: Unlike traditional prototype replacements, prototype CNC machining is highly repeatable. This also means that any finished product manufactured using CNC machining is a replica of the CNC machining prototype. If a manufacturer needs to consistently produce the same product, the CNC prototype should be an identical copy of the prototype design, thereby achieving consistency from batch to batch.

- High precision: CNC machining provides tight tolerances and high precision, making the prototype fit for its original purpose. And because the machining process is precise, it can also help manufacturers find design flaws.

- Save time and money: Prototype CNC machining does not require any tooling or time-consuming prerequisites. You only need to modify the CAD/CAM file to make modifications to the prototype, CNC machine it again, and get it back in no time. In this process, you need to spend a little time. In the long run, any defects and quality problems can be solved by modifying the CAD files, saving a lot of capital costs.

- Material Versatility: CNC machining prototypes can use a variety of highly machinable materials. Manufacturers can choose from the strongest metals and alloys to materials such as wood and plastic. Therefore, the prototyping process can be done using the same material as the final part, which is a great advantage.

Limitations of prototype CNC machining

Of course, there are some limitations when using CNC machining prototypes. Knowing these limitations will allow you to take advantage of the benefits of it.

- Subtractive method: Prototype CNC machining is the creation of the final part by removing material from the initial workpiece. Therefore, more material may be consumed during processing, resulting in an increase in material cost.

- Geometric limitations: CNC prototype machining processing is carried out from the outside to the inside, so it may not be possible to achieve some special geometric states.

- Technical expertise: Prototyping with CNC requires a certain amount of expertise as well as technical expertise. For example, the production of CAD files and the operation knowledge of CNC machine tools.

Extra Tips: Get the best prototype CNC machining service

CNC prototyping has many advantages and can bring you many benefits. But all these benefits come from having a great partner.

At Want.net, you can bring CAD blueprints to life the way you want them to. With our rich service experience and advanced machines, we can assist you in completing your CNC design excellently.

At the same time, at Want.net, you don’t need to wait for a long time to get a quotation, just upload your CAD file and you can get a quotation.

Conclusion

By now, you already know that CNC machining prototyping is one of the best ways to prototype parts. Because it can save you a lot of time and cost. In addition, due to the high precision, you can also use CNC prototyping to assist you in optimizing part design defects and creating high-quality components.

Other Articles You Might Enjoy

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…