In the realm of CNC machined parts, achieving the perfect balance of strength, flexibility, and durability often requires meticulous heat treatment processes. One such crucial process is annealing, especially for copper and its various alloys. Annealing not only relieves internal stresses but also enhances the metal’s workability and overall performance. Let’s delve into the fascinating world of copper annealing and discover how it influences CNC machining parts.

Understanding Annealing: The Basics

Annealing is a heat treatment process that involves heating the metal to a specific temperature, maintaining that temperature for a set period, and then cooling it down. This process alters the physical and sometimes chemical properties of the material, making it softer and more ductile. For copper and its alloys, annealing primarily aims to reduce hardness, improve machinability, and eliminate internal stresses caused by prior work hardening.

Annealing of Pure Copper

Pure copper, often referred to as industrial copper or “red copper,” typically undergoes recrystallization annealing. The purpose here is to soften the metal and refine the grain structure. The usual annealing temperature for pure copper ranges between 400°C and 650°C. However, care must be taken to avoid hydrogen embrittlement, especially in oxygen-rich environments. Therefore, annealing is often done in a controlled atmosphere to prevent such issues.

Here is a typical annealing specification for pure copper:

| Material | Annealing Temperature (°C) | Hot Working Temperature (°C) | Typical Softening Temperature (°C) |

|---|---|---|---|

| C10 | 475 – 750 | 780 – 875 | 400 – 650 |

| T1, T2, T3 | 400 – 650 | 750 – 900 | 380 – 700 |

After annealing, the grain size of copper depends on the annealing temperature and holding time. At lower temperatures (below 550°C), the holding time has a minimal effect. However, at higher temperatures, holding time significantly influences grain size. To avoid overly large grains, it’s essential to minimize holding time at higher temperatures.

Annealing of Brass

Brass, an alloy of copper and zinc, also undergoes annealing primarily for recrystallization and stress relief. Brass’s recrystallization temperature varies depending on its composition but generally falls between 300°C and 400°C. For complete recrystallization annealing, the temperature usually ranges from 600°C to 700°C.

Here’s how different brass types respond to annealing:

| Brass Type | Stress Relief Annealing Temperature (°C) | Recrystallization Annealing Temperature (°C) |

|---|---|---|

| HSn70-1 | 300 – 350 | 550 – 650 |

| HSn62-1 | 350 – 370 | 550 – 650 |

| HAl77-2 | 300 – 350 | 600 – 650 |

| HMn58-2 | 300 – 350 | 600 – 650 |

Higher annealing temperatures can cause grain growth, which negatively impacts the material’s properties. For instance, properly annealed HFe62-0.4 brass can achieve a tensile strength of 415 MPa and an elongation of 34.5%. However, if overheated, the tensile strength can drop to 290 MPa due to grain coarsening.

Annealing of Other Copper Alloys

Copper alloys, such as bronze and cupronickel, also require specific annealing processes. For example, aluminum bronzes may need slow cooling to avoid brittleness, while cupronickel alloys need precise control to prevent grain boundary embrittlement.

Here’s a brief guide to the annealing of various copper alloys:

| Alloy | Intermediate Annealing Temperature (°C) | Final Annealing Temperature (°C) | Holding Time (min) |

|---|---|---|---|

| H96, H90, HFe59-1 | 600 – 700 | 550 – 650 | 30 – 40 |

| QSn6.1-5, QSn6.5-0.4 | 650 – 750 | 500 – 600 | 30 – 40 |

| HPb63-3 | 630 – 700 | 500 – 600 | 40 – 60 |

Avoiding Hydrogen Embrittlement

A critical aspect of annealing copper is avoiding hydrogen embrittlement, particularly in oxygen-containing copper. This issue arises when hydrogen reacts with oxides in the copper, leading to internal cracks. To prevent this, copper should be annealed in slightly oxidizing or inert atmospheres, or the temperature should be kept below 500°C where diffusion of hydrogen and its reaction with oxides is minimal.

Cooling Techniques Post-Annealing

The cooling rate post-annealing also significantly affects the properties of copper and its alloys. For pure copper and single-phase brass (alpha brass), air cooling or water quenching can be used. Water quenching often results in a cleaner surface by removing oxide scales. For dual-phase brass (alpha-beta brass), the cooling rate influences the final mechanical properties. Rapid cooling results in finer precipitates and slightly higher hardness, while slower cooling enhances ductility.

Stress Relief Annealing

Stress relief annealing is vital for components subjected to significant cold work, such as high-zinc brass. It helps to eliminate residual stresses that can cause stress corrosion cracking. This process is usually conducted at temperatures 30-100°C lower than recrystallization temperatures, around 230-300°C, and held for 0.5 to 1 hour.

Special Phenomena: Annealing Hardening and Low-Temperature Annealing

Interestingly, certain copper alloys, such as those with high zinc or aluminum content, exhibit a phenomenon known as annealing hardening. After cold deformation, when these alloys are annealed below recrystallization temperatures (or even just stored for long periods), their hardness increases instead of decreasing. This is due to the ordering of atoms in the crystal lattice, which causes internal strain and increased hardness.

For example, Cu-63.67% Zn alloys (brass) show significant strengthening when annealed at 235°C after 50% cold deformation. This is particularly useful for elastic materials, enhancing their elastic limit and overall performance.

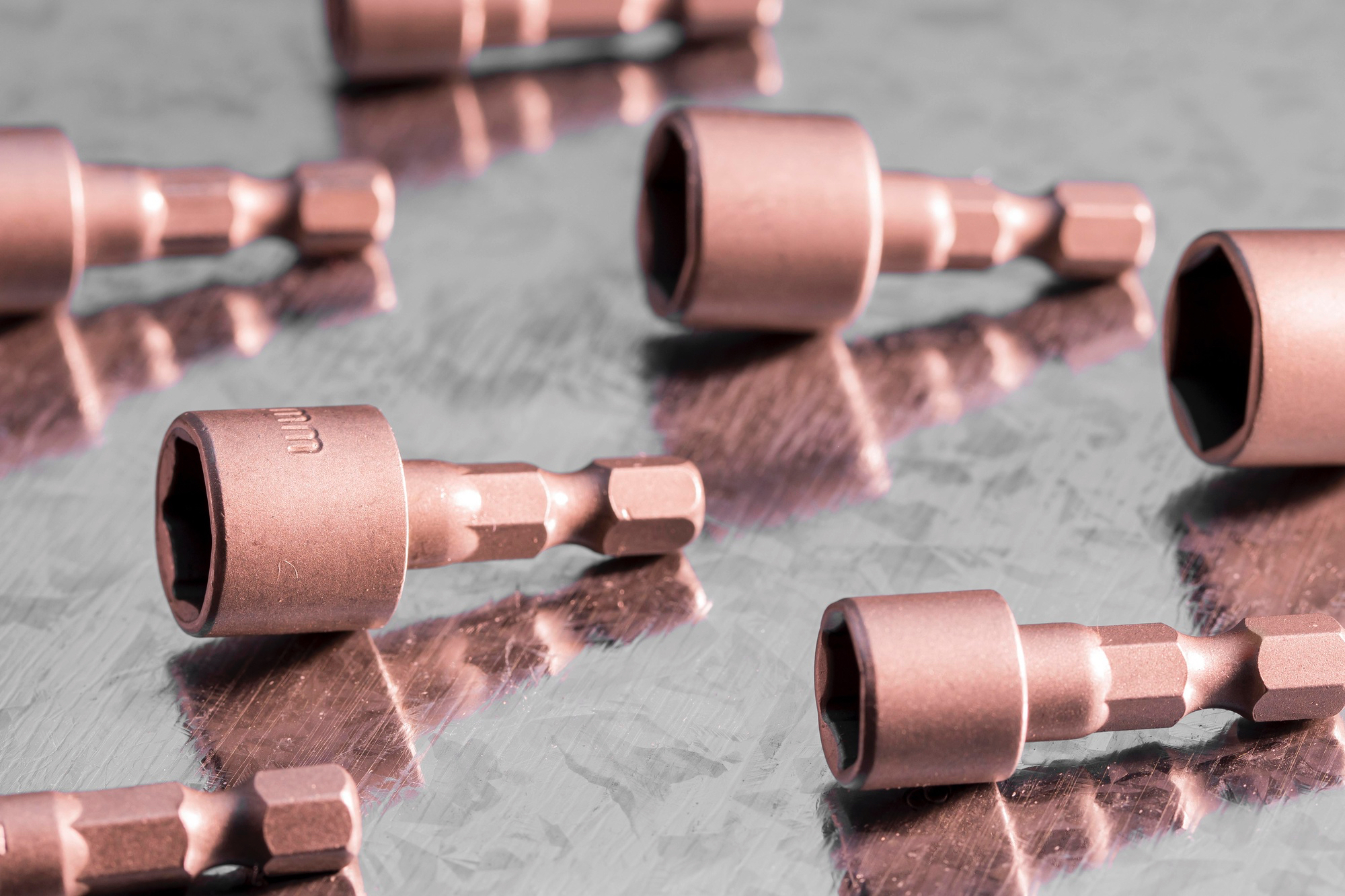

Practical Applications in CNC Machining

In CNC machining, controlling the annealing process of copper and its alloys ensures that the parts achieve the desired mechanical properties, such as enhanced strength, ductility, and reduced residual stresses. This is crucial for parts that require precise dimensions and high surface quality.

For instance, parts made from brass, often used in fittings and valves, benefit from annealing to ensure they withstand mechanical and thermal stresses during operation. Similarly, electrical components made from high-conductivity copper require annealing to maintain their electrical properties and facilitate further machining.

Annealing is a vital process in the treatment of copper and its alloys, significantly influencing their performance in CNC machining parts. By carefully controlling the annealing temperature, atmosphere, and cooling rate, manufacturers can produce parts that meet stringent performance criteria. Understanding these processes allows for better design and manufacturing of high-quality CNC machined components.

Other Articles You Might Enjoy

- The Future of CNC Machining Parts with Environmentally Friendly Brass Alloys

As industries strive to become more environmentally conscious, the materials used in CNC machining are evolving. One of the most significant changes in this domain is the shift from traditional…

- Mastering Chemical Coloring for CNC Machining Copper Parts

In the world of metal surface finishes, chemical coloring has gained significant traction, especially for aluminum and copper. This technique not only enhances the aesthetic appeal of the parts but…

- Enhancing Durability with Copper and Nickel Plating on CNC Machining Parts

Electroplating is like giving metal parts a shiny, protective armor. Imagine turning a dull, rusty piece of metal into a gleaming, robust part ready to withstand the test of time.…

- Copper Alloys in CNC Machining: C10100 vs. C11000

Copper Alloys and CNC Machining: An Introduction In the world of Computer Numerical Control (CNC) machining, materials play an essential role in producing quality results. Among these materials are copper…

- Requirements for CNC Machining Parts

Preparation Work Complete the necessary preparation before machining, including process analysis, process route design, tool and fixture selection, and program compilation. online cnc machining service Operating Steps and Contents Start…

- Precision Engineering: The Advantages of Using Copper Alloys in CNC Machining

Introduction to Precision Engineering and CNC Machining Precision engineering is a discipline that aims at designing machines, fixtures, and other structures that possess high levels of accuracy and stability. It…