Computer Numerical Control (CNC), popular vital technology in various manufacturing industries, has significantly revolutionized traditional fabricating processes like drilling, milling, and cutting. One standout process within this transformative tool is CNC Turning. Coupled with the use of different types of rivets, CNC Turning has availed diverse possibilities for enhanced productivity, precision, and efficiency in fabrication.

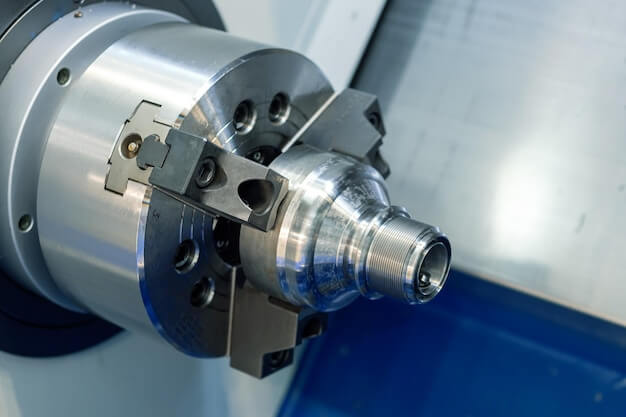

CNC turning is a highly automated machining process where material bars are held in a chuck and rotated as a tool is fed to the workpiece to remove excess material, leaving behind a finished product. The most significant advantages of integrating CNC turning into fabrication includes high production speed, minimal wastage, multiple design options, consistency, and accuracy.

Producing a variety of components using CNC turning follows a series of steps. First, it requires a detailed and precise CAD design, which guides the CNC machine in producing an exact replica of the model. After finalizing the model, an expert programmer inputs the necessary commands on the CNC system. This meticulous instruction inputing stage defines the operation sequence, automation level, and safety measures during fabrication.

As you compare CNC turning with other traditional methods, one outstanding feature is its ability to produce complex shapes that require sturdy fasteners, such as rivets. In engineering parlance, a rivet refers to a permanent mechanical fastener. When installed, the end of the rivet deforms or ‘upsets’, hence holding together two sections of material.

There’s quite a diversity when it comes to types of rivets used in conjunction with pieces fabricated via CNC turning. The four key types of rivets include blind, drive, solid, and semi-tubular rivets. Each type takes on a unique role depending on application requirements.

1. Blind Rivets: Also known as pop rivets, these are perfect for applications requiring connections at one side. This feature is crucial in CNC turning, especially when producing components with limited access on one side.

2. Drive Rivets: These are installed by driving the center pin into the rivet body, causing it to expand and hold together workpieces. They’re excellent for high-speed applications due to their simple installation process.

3. Solid Rivets: The oldest type of rivet, solid ones provide robust and reliable joints you’d want in a component produced through CNC Turning.

4. Semi-Tubular Rivets: These types work best on softer or brittle materials like plastic, reducing material deformation during assembly. They offer tight bonds between parts, enhancing the durability of CNC machined components.

In essence, the introduction of CNC turning has advanced manufacturing industries significantly; from household products and furniture to automotive and aerospace components. In conjunction with various types of rivets, manufacturers can now create better quality, precise, durable, and complex shapes than before.

However, be ready to invest big time in resources and facilities as CNC machining requires complex equipment and skilled operators. Plus, knowledge about different fasteners such as rivets and where each works best will influence finished product quality hugely.

The complementation of CNC turning with varying types of rivets undoubtedly symbolizes modern technological advances designed to meet dynamic fabrication needs. This pair not only offers efficiency and accuracy but also provides solutions for creating intricate designs that might be impossible with traditional methods. Despite some challenges arising from this tech (including resource allocation and operator skill), the advantages astronomically outweigh these minor hurdles. It’s exciting witnessing how much more we can achieve as technology continues developing at such swift speed.

Other Articles You Might Enjoy

- Innovative CNC Machining for Custom Medical Instruments

Innovative CNC Machining for Custom Medical Instruments Computer Numeric Control (CNC) machining is an innovative automated process that utilizes computer software to control machine tools. The use of CNC machines…

- Aluminum Parts Machining: CNC Techniques for Precision and Efficiency

Introduction to Aluminum Parts Machining and CNC Techniques In the manufacturing industry, the machining of aluminum parts plays a crucial role for its effortless machinability which makes it an ideal…

- Tool Steel Grades in CNC Machining: Which One Should You Choose for Durability?

Introduction to Tool Steel in CNC Machining In the realm of CNC (Computer Numerical Control) machining, tool steel reigns supreme due to its exceptional durability and versatility. As a broad…