Physical Vapor Deposition (PVD) is a surface coating technique used in CNC machining service that involves the deposition of thin films of materials onto a substrate. PVD is a highly effective method of producing high-quality coatings with superior adhesion and durability.

In the PVD process, a solid material is vaporized in a vacuum chamber and then deposited onto the surface of the substrate. The process is carried out at relatively low temperatures, which allows for the deposition of a wide range of materials, including metals, ceramics, and polymers.

One of the primary advantages of PVD is that it produces coatings with exceptional hardness, wear resistance, and corrosion resistance. These coatings are ideal for use in high-wear applications, such as cutting tools, molds, and dies, which are commonly produced using CNC machining service.

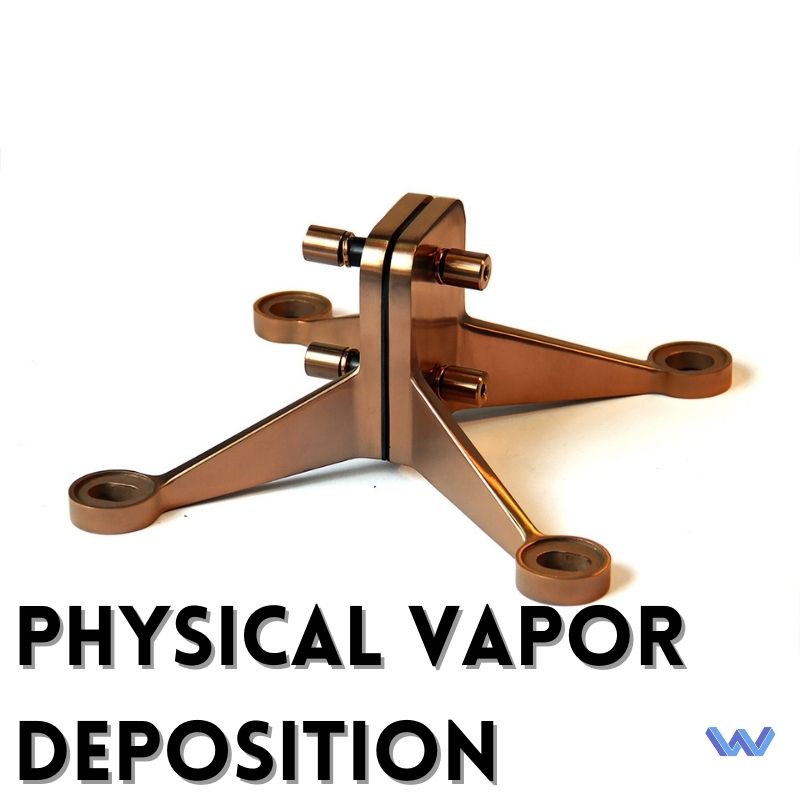

Another benefit of PVD coatings is that they can be tailored to meet specific requirements, such as surface finish, thickness, and color. This makes PVD a highly versatile and customizable coating method, which is especially important in CNC machining service, where precision and consistency are crucial.

Physical Vapor Deposition is a highly effective surface coating technique that is widely used in CNC machining service. With its exceptional hardness, wear resistance, and customization capabilities, PVD is an ideal solution for producing high-quality coatings for a wide range of applications.