Introduction: The Intricacies of Compressor Blade Geometry

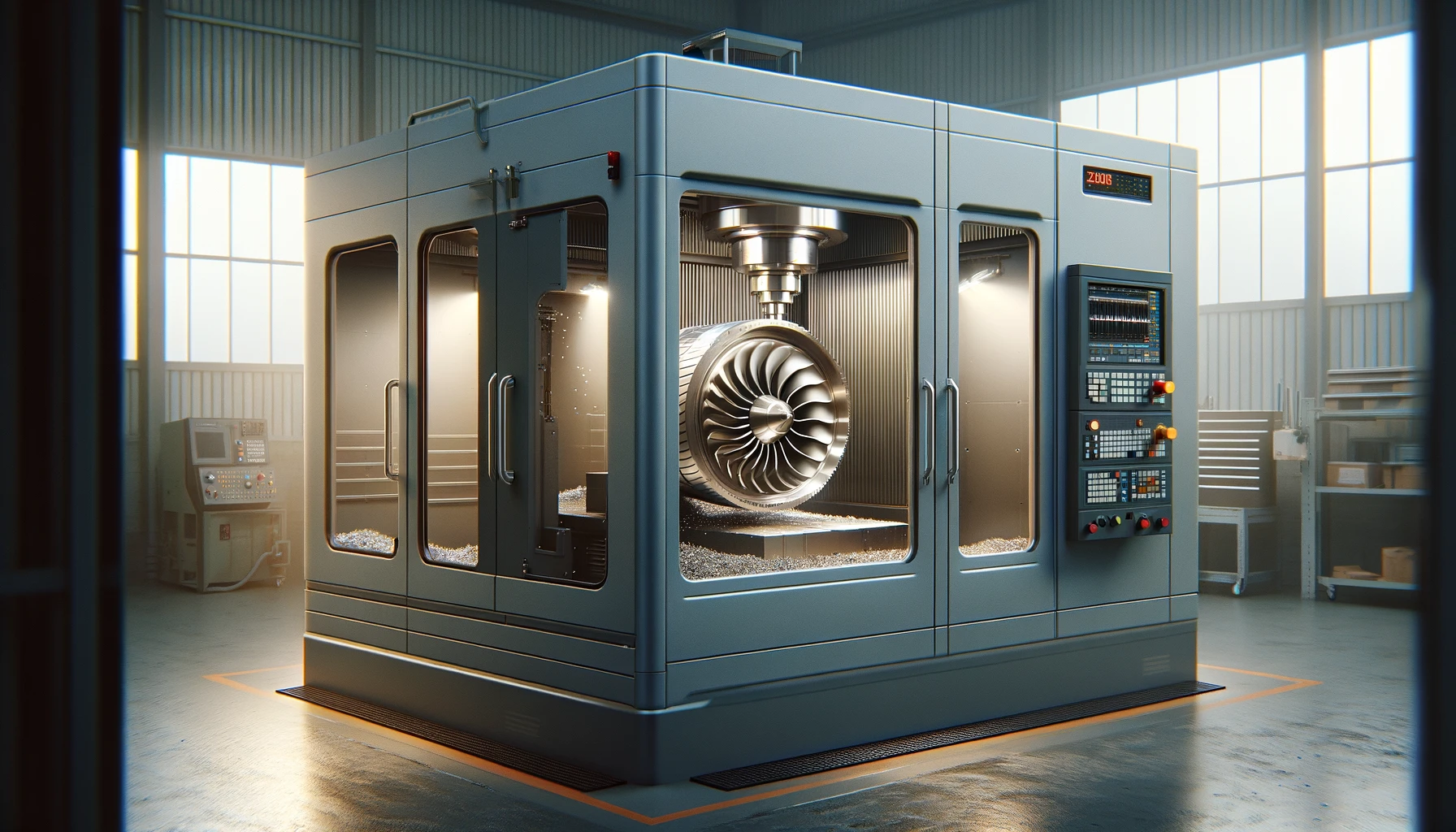

In the intricate world of aerospace and industrial machinery, the compressor blade stands as a testament to modern engineering’s capability to push boundaries. These blades, vital for the efficient operation of jet engines and various compressors, embody the pinnacle of design precision. The geometry of compressor blades is a marvel of engineering, optimized to convert high-speed, chaotic airflows into a controlled and directed force, thereby maximizing efficiency. The intricate shapes, which include complex curves and precise angles, are critical for their functionality. Each blade must be crafted to exact specifications, with even the slightest deviation potentially leading to significant performance losses. The challenges of machining such complex geometries are vast, encompassing not only the technical aspects of CNC machining but also the material sciences and aerodynamic principles that dictate the blade’s final form. This article aims to explore these challenges in depth, shedding light on the crucial role of China’s CNC precision machining in realizing the potential of these advanced designs.

The Role of China CNC Technology in Precision Machining

China’s leadership in CNC technology has become a cornerstone in the global machining landscape, especially in the high-stakes field of compressor blade manufacturing. In order to meet the needs of global customers, Chinese companies also provide CNC parts online services .The precision machining capabilities found within China’s borders are not just a matter of national pride but a critical component in a global infrastructure that demands absolute precision and reliability. This technology’s journey from its nascent stages to its current state-of-the-art form is a testament to China’s dedication to excellence in engineering and manufacturing.

- Innovation in Machining Practices: Chinese CNC technology has evolved through relentless innovation and refinement of machining practices. This evolution has been marked by significant milestones, including the development of ultra-precise cutting tools and the integration of AI-driven predictive maintenance systems.

- Adoption of Advanced Materials: The shift towards materials that offer superior strength-to-weight ratios, such as titanium alloys and carbon fiber composites, has necessitated advancements in CNC machining techniques to handle these materials effectively.

- Precision Control Systems: The introduction of more sophisticated control systems has allowed for unprecedented levels of precision in CNC machining, enabling the intricate geometries of compressor blades to be realized with minimal error.

- Collaborative Robotics: The integration of collaborative robotics into CNC machining processes has opened new avenues for efficiency, allowing for more complex and precise operations to be conducted with greater consistency.

- Sustainability in Machining: With an eye towards sustainability, advancements in CNC technology have also focused on reducing waste and energy consumption, aligning with global efforts to minimize environmental impact.

Analyzing the Complex Shapes of Compressor Blades

The design of compressor blades is a sophisticated blend of aerodynamics and material science, aimed at achieving the highest efficiency in air compression and turbine performance. The complexity of these shapes arises from the need to optimize airflow across a range of operating conditions, necessitating a precise balance between curved surfaces, sharp edges, and overall blade geometry. This optimization process involves extensive computational modeling and simulation to predict airflow patterns, stress distributions, and potential points of failure. The intricate curvature of the aerofoil, the blade’s thickness distribution, and the twist along its length are all carefully designed to maximize aerodynamic efficiency and minimize drag, leading to significant challenges in CNC machining processes that require advanced capabilities in terms of equipment, programming, and operational precision.

Challenges in CNC Machining Aerofoil Surfaces

CNC machining of aerofoil surfaces involves addressing multiple challenges that arise from the need to replicate complex geometries with high precision. These surfaces are crucial for the blade’s performance, requiring meticulous attention to detail to ensure that the finished product adheres to the stringent specifications demanded by aerospace applications. Challenges include maintaining the integrity of the surface to avoid any defects that could impair aerodynamic performance, achieving tight tolerances that are often within micrometers to ensure the blade’s efficiency, and preventing material deformation that could arise from the heat and stress of machining. Overcoming these challenges necessitates a combination of advanced CNC technology, skilled operators, and rigorous quality control measures to ensure that each blade meets the exacting standards required for its intended application.

The table below provides a brief summary of important matters:

| Challenge | Description | Strategy |

|---|---|---|

| 1. Surface Integrity | Maintaining defect-free surfaces is crucial for airflow efficiency. | Implement high-resolution surface scanning and adaptive machining. |

| 2. Tolerance Maintenance | Tight tolerances are paramount for aerofoil precision. | Utilize advanced feedback systems for real-time adjustments. |

| 3. Material Deformation | Machining-induced stress can alter material structure. | Optimize tool paths and employ cooling techniques. |

| 4. Edge Finishing | Precise edge finishing is crucial for maintaining aerodynamic profiles. | Integrate fine-edged milling and polishing processes. |

| 5. Tool Precision | The precision of CNC tools directly impacts the machining quality. | Regular calibration and employing ultra-precise cutting tools. |

| 6. Vibration Minimization | Machine-induced vibrations can affect surface smoothness and precision. | Use vibration damping technologies and optimize machine setup. |

| 7. Heat Management | Excessive heat can lead to material expansion and deformation. | Implement advanced cooling systems and temperature-controlled environments. |

| 8. Chip Removal | Efficient chip removal is necessary to prevent re-cutting and surface damage. | Use high-pressure coolant systems and chip removal strategies. |

| 9. Material Compatibility | Selecting the right tool material for specific workpiece materials is crucial to prevent wear. | Conduct compatibility tests and material studies to select optimal tool materials. |

| 10. Inspection and Verification | Ensuring each blade meets specifications is critical for performance. | Employ advanced metrology techniques and automated inspection processes. |

Optimizing CNC Tool Paths for Complex Geometries

Effective tool path optimization is crucial for ensuring the high-quality production of compressor blades. This involves the use of sophisticated CAM (Computer-Aided Manufacturing) software that can analyze the blade’s 3D model and determine the most efficient cutting strategy. The software must account for the cutting tool’s geometry, the material properties of the blade, and the capabilities of the CNC machine to create a path that minimizes machining time while ensuring precision.

| Step | Process Description | Impact |

|---|---|---|

| 1. Initial Analysis | 3D model analysis to identify critical features and potential challenges. | Ensures comprehensive understanding of the machining requirements. |

| 2. Tool Selection | Choosing the optimal tool based on material and geometry. | Affects machining efficiency and surface finish quality. |

| 3. Roughing Strategy | Planning the removal of large material volumes. | Reduces machining time and prepares the piece for finishing. |

| 4. Finishing Strategy | Detailed path planning for surface finishing. | Critical for achieving the required surface quality and tolerances. |

| 5. Simulation | Virtual machining to predict potential issues. | Prevents real-world errors and reduces trial runs. |

| 6. Optimization | Adjusting paths based on simulation results. | Enhances efficiency and quality while reducing wear. |

| 7. Verification | Comparison against the original design for accuracy. | Ensures the final product meets all design specifications. |

| 8. Feedback Loop | Incorporating learnings into future path planning. | Continuously improves the machining process. |

Ensuring Precision and Consistency in Tight Tolerances

Achieving and maintaining the tight tolerances required for compressor blades is a multifaceted challenge that involves every stage of the CNC machining process. From initial material selection and tool calibration to the final inspection, each step must be meticulously managed to ensure that the final blade meets the exacting standards required for its operation.

| Factor | Challenge | Mitigation Strategy |

|---|---|---|

| Material Properties | Variations in material can affect machining behavior. | Strict material selection and pre-machining treatment processes. |

| Tool Wear | Deterioration of tool edges affects precision. | Implement tool wear monitoring systems and scheduled replacements. |

| Machine Calibration | Even slight misalignments can lead to errors. | Regular machine calibration and maintenance routines. |

| Thermal Expansion | Heat generated during machining can alter dimensions. | Advanced cooling techniques and temperature-controlled environments. |

| Vibration | Machine and tool vibrations can degrade precision. | Use of vibration damping systems and optimized tool paths. |

| Work Holding | Insecure holding can lead to movement and errors. | Employ advanced clamping and fixture systems for stability. |

| Measurement Accuracy | Errors in measurement can lead to tolerance issues. | Utilize high-precision measurement tools and frequent checks. |

| Process Variability | Variations in the machining process can introduce inconsistencies. | Standardize processes and implement quality control checkpoints. |

The Importance of Material Selection in Machining Compressor Blades

The selection of the appropriate material for compressor blades is critical not only for the blade’s performance but also for the machinability and longevity of the component. Materials must be chosen based on their ability to withstand the operational stresses they will encounter, including high temperatures, rotational forces, and corrosion, while also being conducive to precision CNC machining.

| Material | Properties | Machinability | Applications |

|---|---|---|---|

| Titanium Alloys | High strength-to-weight ratio, excellent corrosion resistance. | Challenging due to work hardening. | High-performance blades where weight is critical. |

| Stainless Steels | Good strength and corrosion resistance. | Generally good with the right tooling and parameters. | Widely used for its balance of properties and cost. |

| Nickel Alloys (e.g., Inconel) | Exceptional high-temperature strength. | Difficult, requires specialized tooling and slow speeds. | Blades in high-temperature environments. |

| Aluminum Alloys | Lightweight and good corrosion resistance. | Excellent, though softness requires careful handling. | Low-stress applications, often in smaller compressors. |

| Composites (e.g., Carbon Fiber) | High strength-to-weight ratio, customizable properties. | Requires specialized machining strategies. | Advanced applications seeking weight reduction and strength. |

| Ceramics | Excellent high-temperature performance, wear resistance. | Brittle, requiring non-traditional machining methods. | Specialized applications needing extreme temperature resistance. |

Incorporating the right material into the design and manufacturing process of compressor blades ensures that the final product not only meets the desired performance criteria but is also cost-effective and durable over its operational lifespan.

Advanced Techniques and Innovations in CNC Machining

The field of CNC machining is constantly evolving, with new techniques and innovations continually emerging to enhance the machining of complex components like compressor blades. This section highlights some of the latest advancements in CNC technology, including 5-axis machining, ultra-precision machining, and the use of laser and electron beam machining. These innovations have significantly expanded the capabilities of CNC machining, offering new possibilities for the design and production of compressor blades.

Conclusion: Overcoming Challenges with Advanced CNC Solutions

The production of compressor blades encompasses a broad spectrum of challenges, from intricate design requirements to stringent manufacturing tolerances. However, the ongoing advancements in CNC technology, particularly those emanating from China, provide robust solutions to these challenges. Through a combination of advanced machining techniques, sophisticated software, and innovative materials, the CNC machining of compressor blades continues to achieve new levels of precision and efficiency, ensuring the production of components that meet the highest standards of quality and performance.

Other Articles You Might Enjoy

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Simplifying Complex Workpieces with CNC Machining Technology

In the ever-evolving landscape of enterprise development, the shapes and structures of workpieces to be processed have become increasingly diverse and complex. This poses a significant challenge for enterprises utilizing…