PEEK vs. ABS: A Guide to Choosing Injection Molding Materials

Understanding the Importance of Material Selection in Injection Molding Injection molding, a prevalent manufacturing method, requires meticulous attention towards selecting the appropriate material. The choice between materials such as PEEK and ABS can significantly impact not only the production process but also the attributes and applications of the final product. Both these thermoplastics have unique […]

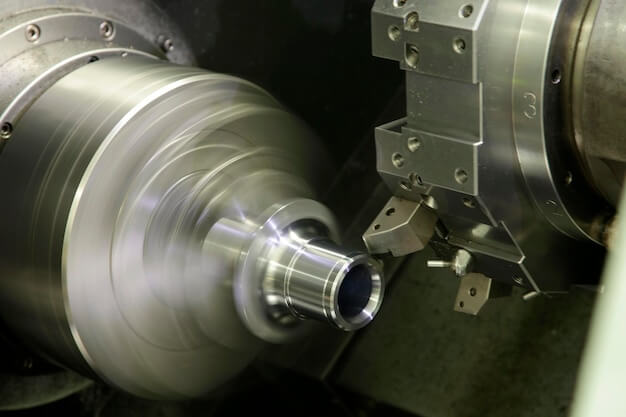

Selecting the Right Surface Finish for Your CNC Machined Part: Matte vs. Glossy Materials

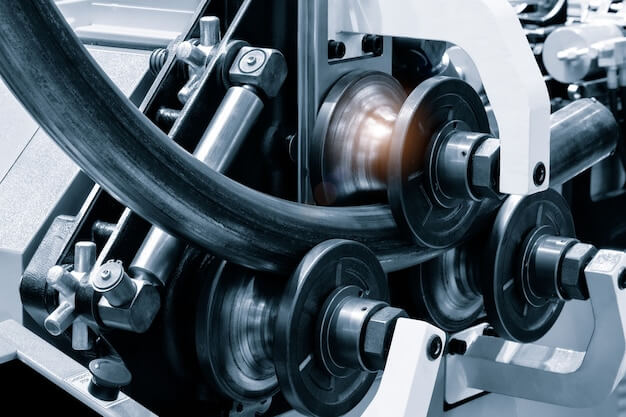

Selecting the Right Surface Finish for Your CNC Machined Part: Matte vs. Glossy Materials CNC machining, an abbreviation of Computer Numerical Control machining, is a precise and complex process that utilizes computers to control machine tools. The complexity of this process frequently involves milling, drilling, and turning materials into finished parts with high precision. As […]

Enhancing Aesthetic Appeal in CNC Machining: Anodized Aluminum vs. Painted Steel

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a high-precision manufacturing process that uses pre-programmed computer software to direct the movement of complex machinery tools. This technological approach proves extremely important and beneficial within various sectors of production given its ability to produce intricately designed parts with impeccable accuracy and precision. What makes […]

Laser Cutting Materials: MDF vs. Plywood – What’s Best for Your Project?

Introduction to MDF and Plywood in Laser Cutting In the world of laser cutting materials, Medium Density Fibreboard (MDF) and plywood are commonly used resources. These two materials offer unique benefits for different types of projects. MDF, a composite panel product typically consisting of cellulosic fibers combined with a synthetic resin or other suitable bonding […]

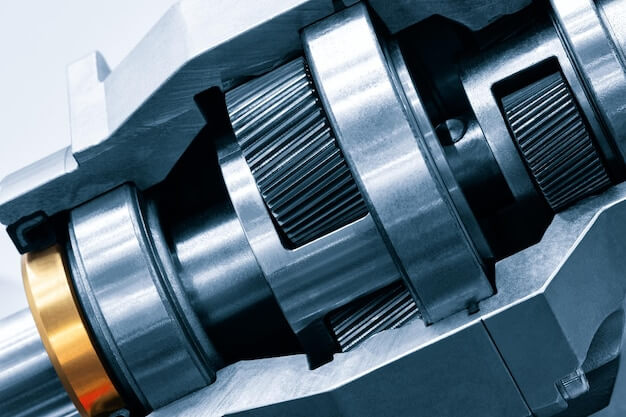

The Impact of Material Density on CNC Machining Costs and Efficiency

The Importance and Role of CNC Machining in Manufacturing CNC (Computer Numerical Control) machining is a critical element within modern manufacturing. As an advanced technology, it precisely automates the machinery processes, ranging from milling to lathing, through pre-programmed computer software. This accuracy significantly reduces errors, optimizes resource use, and ultimately improves productivity. Practical examples demonstrate […]

The Engineer’s Guide to Machining Composites: Challenges and Material Selection

Introduction to Machining Composites The process of machining composites, a field that utilizes a variety of substances with different properties skillfully merged to create a new material possessing unique characteristics. It encapsulates the application of various operations such as cutting, drilling, and grinding on composites to obtain desired shapes or finishes. Engineered composite materials stand […]

HDPE vs. LDPE: A Detailed Comparison for Manufacturers

Introduction: Understanding HDPE and LDPE In the realm of plastics, High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) play significant roles. HDPE is a rigid plastic material with an industrial strength robustness, offering high load-bearing capacity and impact resistance; these unique attributes make it ideal for heavy-duty applications such as water pipes, fuel tanks or outdoor […]

Navigating the World of Non-Metal CNC Machining: Wood vs. Plastic Material Insights

Introduction to CNC Machining: Special Focus on Wood and Plastic Materials CNC machining, or Computer Numerical Control machining, is a manufacturing process wherein pre-programmed computer software controls the movement of factory equipment and tools. It’s vastly beneficial for managing complex three-dimensional cutting processes. While this technique finds applications with an array of materials, our focus […]

The Art of CNC Machining: Aesthetic Materials for Consumer Products

Introduction to CNC Machining and its Aesthetic Significance in Consumer Products CNC Machining, known formally as Computer Numerical Control Machining, serves a significant role in producing consumer products. This technique uses computers to control machine tools for an accurate and efficient production process. The focus of this article touches upon the crucial use of aesthetic […]

CNC Machining in Robotics: Material Selection for Durability and Functionality

Introduction: The Significance of CNC Machining in Robotics and the Importance of Material Selection The field of robotics has significantly benefited from the advancements in Computer Numeric Control (CNC) machining. This technology enables precision manufacturing that is essential for crafting intricate components without compromising quality or efficiency. Notably, material selection plays a vital role in […]

ABS Plastic vs. Nylon: A Detailed 3D Printing Material Comparison

Introduction: The Importance of Material Selection in 3D Printing In the field of 3D printing, material selection plays a pivotal role in determining not only a product’s aesthetic quality, but also its functionality and durability. Different materials across the spectrum from ABS plastic to nylon offer unique advantages based on their distinct properties. ABS Plastic: […]

Strategies for Enhancing Thermal Conductivity in CNC Machined Parts

The Importance of Thermal Conductivity in CNC Machined Parts In the sphere of CNC machining, thermal conductivity is an extremely vital factor. It has crucial effects on both performance and longevity of machined parts, significantly influencing overall efficiency of the system. Materials with high thermal conductivity transfer heat more effectively, hence extending the life span […]