Know Your Materials: Delrin

Introduction to Delrin Delrin, Polyoxymethylene (POM), known for its high tensile strength and durability, stands out in the realm of thermoplastics. Its molecular structure showcases a series of -CH2O- units, deriving from its formaldehyde polymer base. As an engineering plastic, Delrin is prized for resilience; resistance to friction, wear, and moisture adds to its unique […]

what are the different types of springs

Importance and Function of Springs Springs are indispensable mechanical components utilized in a myriad of applications to store energy, cushion impacts, maintain tension or compression between surfaces, and control motion. They serve as the backbone of many mechanical systems found in industrial machinery, electronics, automotive suspensions, and even household items like pens and mattresses. By […]

design for 3d printing how to reduce your cost

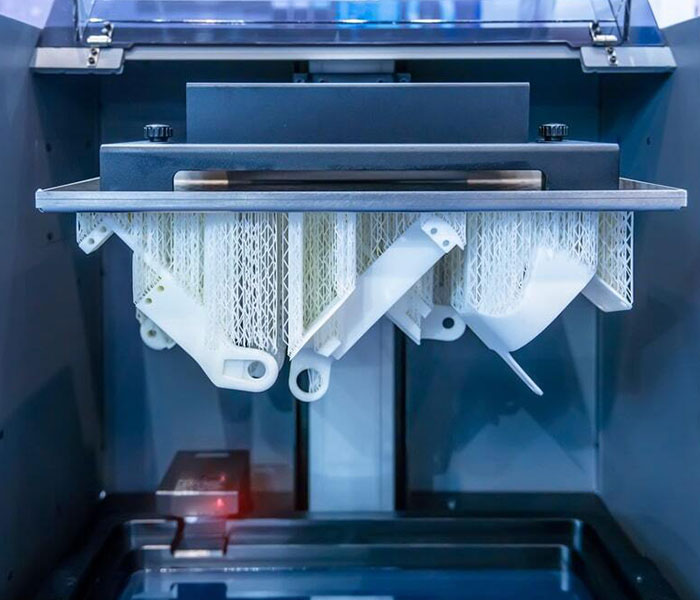

Relevance and Benefits of Cost Reduction in 3D Printing In an era where innovation is pivotal, 3D printing emerges as a transformative force across numerous industries, from manufacturing complex aerospace components to creating bespoke medical devices. However, the cost associated with this technology can often be a barrier to entry or expansion. Minimizing expenses in […]

Delrin in CNC machining technology

Delrin, a trademarked name for polyoxymethylene (POM), is an engineering thermoplastic known for its high strength, rigidity, and resistance to friction and wear. This semi-crystalline plastic boasts exceptional dimensional stability and ease of machining, making it a favored material in precision parts manufacturing. In the realm of CNC machining—a computer-controlled subtractive process used to create […]

What Is the Difference Between Acetal Plastic and Delrin?

Brief Overview of Engineering Plastics Engineering plastics are a group of plastic materials that have better mechanical and thermal properties than the more widely used commodity plastics (such as polystyrene, PVC, polypropylene, and polyethylene). Being more robust, durable, and resistant to high temperatures, they are often employed in applications that require superior performance. Typical engineering […]

Aerospace CNC Machining: Precision Engineering for the Skies

CNC (Computer Numerical Control) machining stands as a cornerstone in the production of aerospace components, where its application spells the difference between success and catastrophic failure. In an industry that demands absolute precision, CNC machining provides the ability to produce parts with extremely tight tolerances, often down to micrometer-level accuracy. This is not just beneficial […]

Delrin vs Nylon: Comparing the Properties and Applications of Two Popular Engineering Plastics

Engineering plastics have become foundational materials in the design and manufacturing of an array of components, owing to their mechanical strength, durability, and flexibility. Critical to material selection in engineering applications is understanding the unique properties of each plastic. This necessitates a comparison between popular candidates such as Delrin, known for its high tensile strength […]

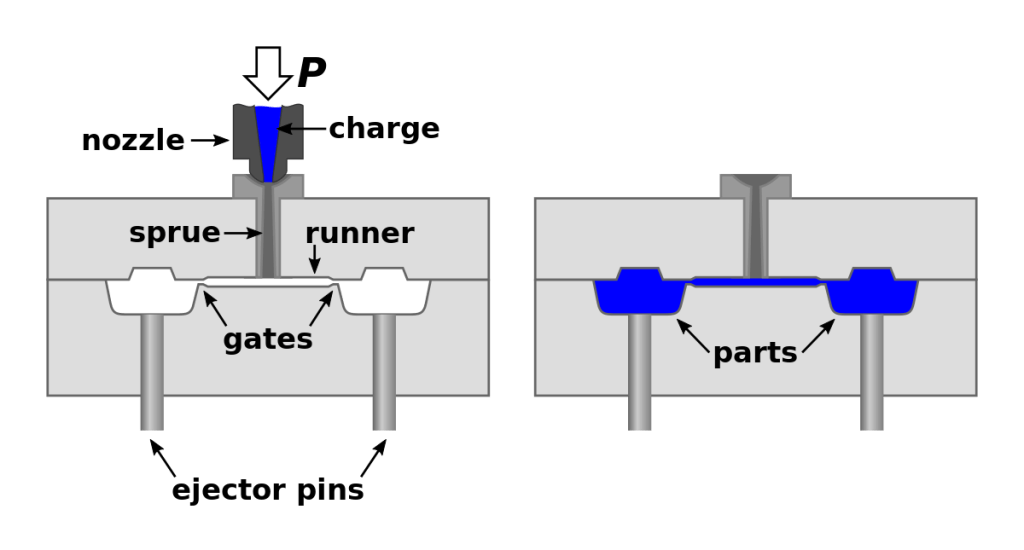

what is insert molding

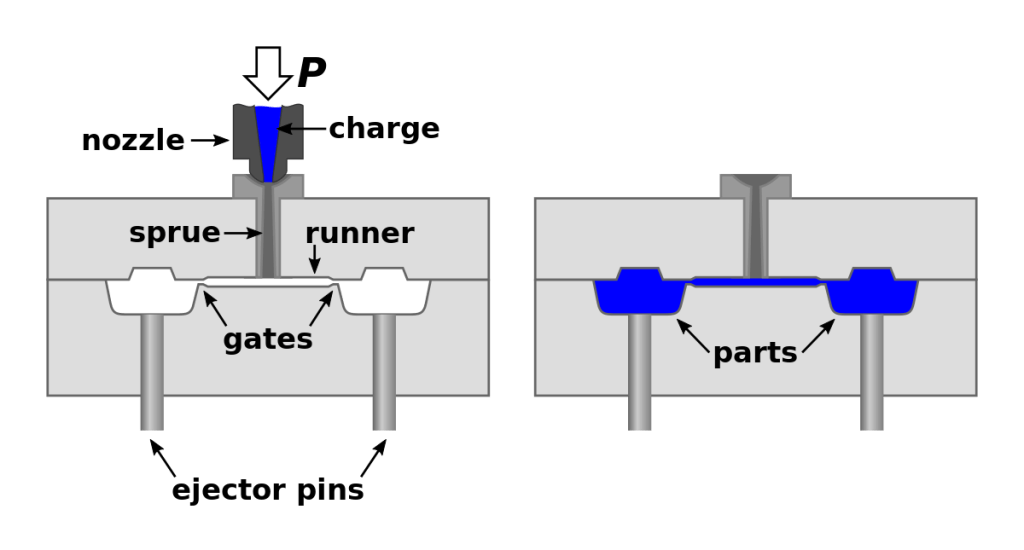

Insert molding is a manufacturing technique where components, often metal parts, are placed into a mold and encapsulated by molten plastic to create a final composite piece with enhanced functionality. This process differs markedly from traditional injection molding, where preformed parts are not typically incorporated into the molded article. The benefits of insert molding include […]

Precision Micro Injection Molding: Essential Advantages and Versatile Applications

Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with high precision. It stands as an essential technique in various industries, particularly where components must be produced on a micro-scale with tight tolerances, such as medical devices or microelectronics. The process involves injecting molten material […]

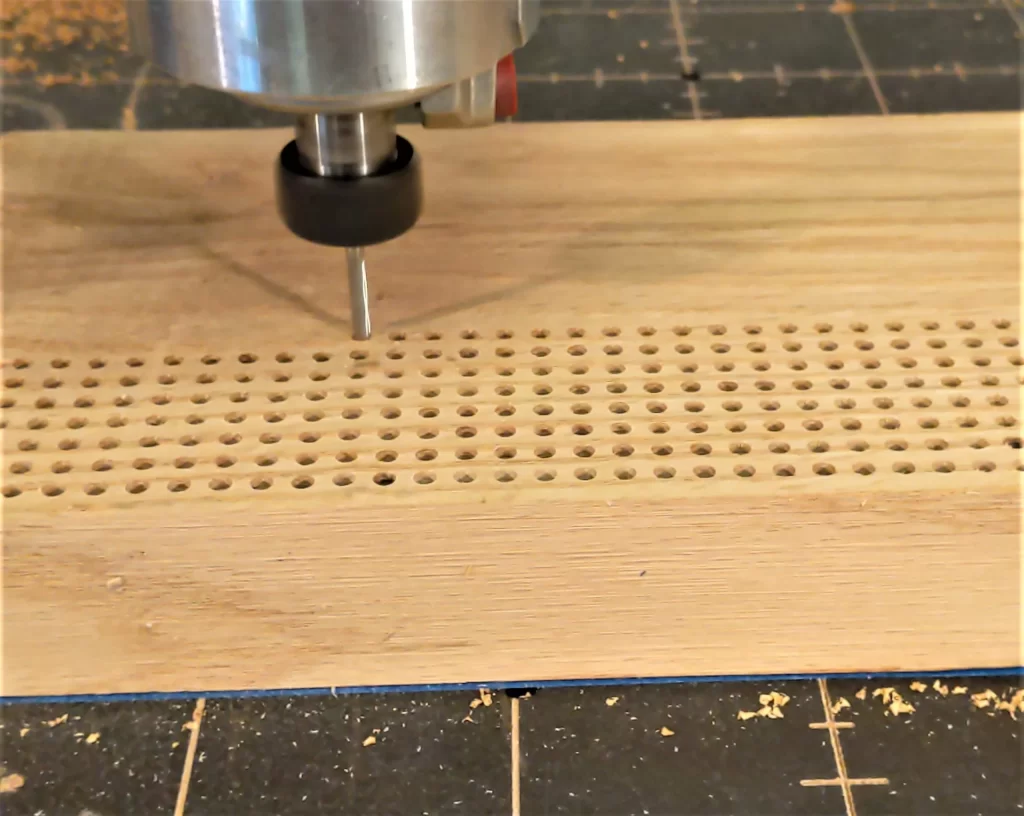

Ultimate Guide to CNC Drilling: Mastering Techniques, Varieties, and Practical Uses

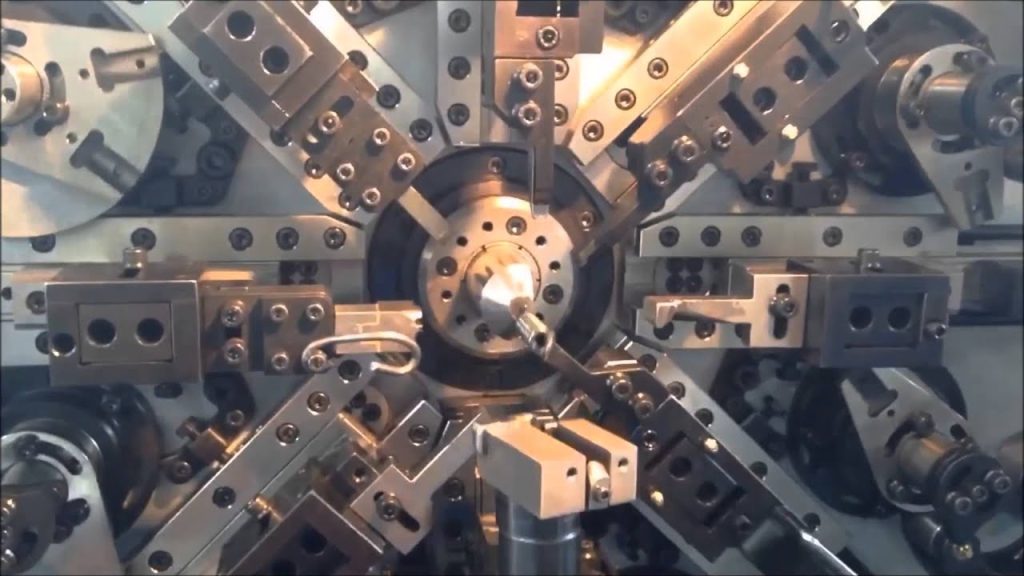

CNC drilling is a precision machining process utilized extensively in the manufacturing sector where holes of various sizes and depths are created in metal, plastic, or wood with high accuracy. It employs computer numerical control (CNC) systems for automating the movement and operation of the drill bits, yielding consistent and repeatable results that are critical […]

CNC Milling vs CNC Drilling? which one to Choose?

In the context of manufacturing and industrial applications, Computer Numerical Control (CNC) processing plays a crucial role. Two such techniques integral to these operations are CNC milling and drilling. 1.1 Definition of CNC Milling and CNC Drilling CNC milling is defined as a machining process where rotating cutting tools remove material from a workpiece in […]

Understanding the Different Types of Plastic for CNC Machining

Title: Understanding the Different Types of Plastic for CNC Machining Introduction CNC machining, a revered and precise manufacturing process, is not limited to metals and alloys. Plastics, with their versatile properties, have become a staple in CNC machining, offering unique advantages in various applications. This article delves into the world of plastics in CNC machining, […]