Transforming CNC Machining for the Future of Clean Energy

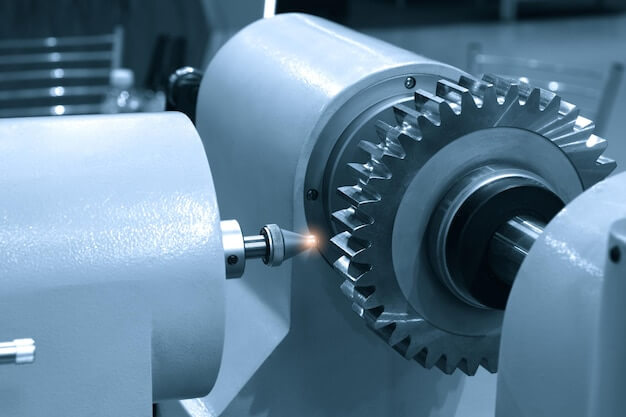

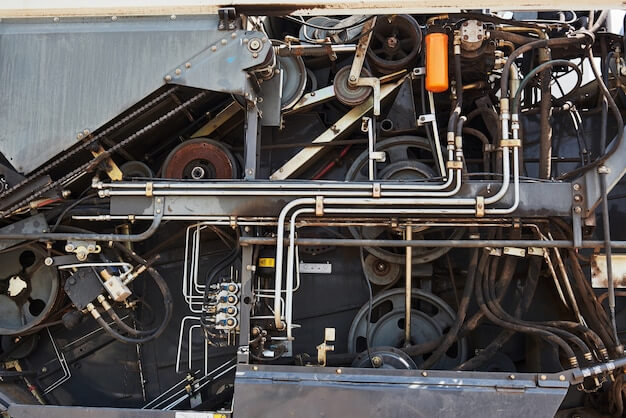

CNC Machining and its Role in Clean Energy In simple terms, CNC machining is a manufacturing process in which pre-programmed computer software guides the movement of factory machinery and tools. This technology allows for precise control over complex tasks that need high levels of accuracy. CNC, standing for Computer Numerical Control, plays a crucial role […]

Precision CNC Machining for High-Performance Racing Boats

Precision CNC Machining: An Introduction The term Precision CNC machining refers to a manufacturing process that utilizes computer numerical controls (CNC) to handle complex machinery tasks in production lines with utmost precision. It combines both the Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) techniques. The system interprets 3D CAD model data into specific instructions for […]

Revolutionizing CNC Machining for High-Tech Consumer Products

Introduction to CNC Machining in High-Tech Consumer Products The Computer Numerical Control (CNC) machining process plays a pivotal role in the manufacturing of high-tech consumer products. With its advanced level of automation, precision and functionality, CNC machines create complex parts and components integral to the creation of an array of everyday well-designed tech gadgets like […]

High-Precision CNC Machining for Advanced Medical Diagnostics

Computer Numerical Control (CNC) Machining in Advanced Medical Diagnostics CNC machining, a manufacturing process that utilizes pre-programmed computer software to dictate the movement of factory tools and machinery, plays an ever-growing role in advanced medical diagnostics. This automated tooling methodology removes layers from a stock piece—also referred to as blank—in a strategic manner to create […]

CNC Machining for Custom Art Installations: Precision and Creativity Combined

Introduction: An Overview of CNC Machining and Custom Art Installations CNC machining, or Computer Numerical Control machining is a modern manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. Utilizing this technology allows manufacturers to create intricately detailed components with immense accuracy and precision. Within the realm of custom art […]

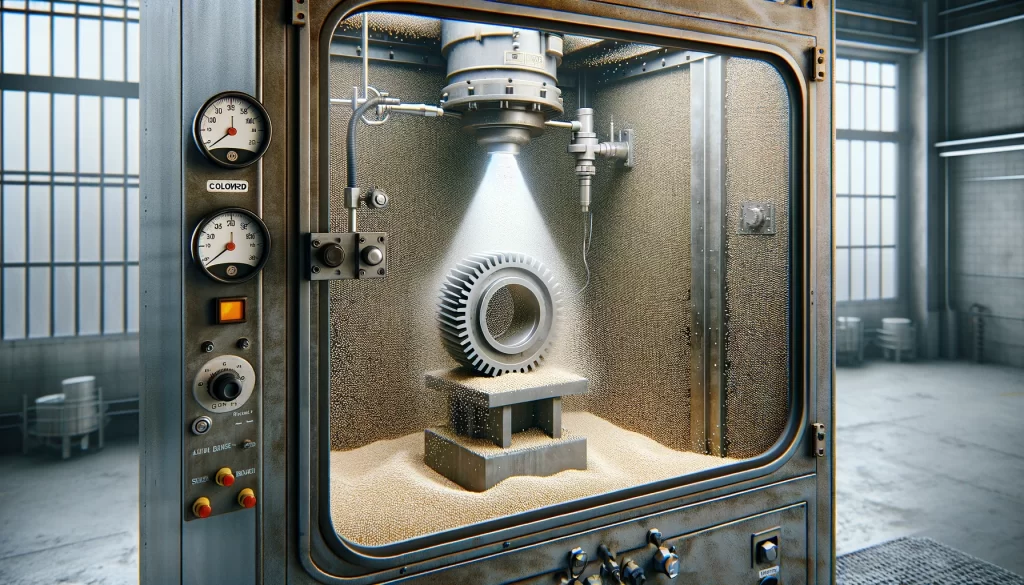

Application of Bead Blasting in Chinese CNC Precision Machining: An Effective Stress Relief Method

Bead Blasting Basics: Understanding Its Role in Stress Relief Bead blasting is a surface finishing technique widely used in the manufacturing sector to clean, smooth, and enhance the appearance of metal parts. In the context of CNC precision machining, bead blasting serves not just an aesthetic function but also a crucial technical role in stress […]

Precision CNC Machining for Advanced Renewable Energy Solutions

Introduction to Precision CNC Machining Precision CNC machining, or Computer Numerical Control machining, is a technology that enables the design and production of complex parts with exquisite accuracy. It plays an integral role in shaping numerous industrial sectors, such as aerospace, healthcare, automotive – essentially any field where precision manufacturing is vital. This revolutionary technique […]

Innovative CNC Machining for Complex Surgical Tools

Introduction to CNC Machining and its Significance in Surgical Tools Manufacturing CNC machining, an acronym for Computer Numerical Control machining, plays a significant role in the manufacturing world. Being an advanced technology that uses computer programs to control machinery tools, it impacts many industries, particularly in creating complex surgical tools. These are crucial instruments used […]

Precision CNC Machining for Cutting-Edge Optical Instruments

Precision CNC Machining for Cutting-Edge Optical Instruments Precision CNC (Computer Numerical Control) machining is a highly specialized technology utilized to cut, shape, and assemble materials with absolute precision. This state-of-the-art method can be effectively applied in the creation of cutting-edge optical instruments; a sub-field currently experiencing rapid advancements. Precision CNC machining makes it plausible to […]

Details Determine Success: Unveiling the Intricacies of Bead Blasting in CNC Machining

Introduction: The Importance of Bead Blasting in CNC Machining In the precision-demanding world of manufacturing, CNC machining represents the gold standard for creating detailed and accurate components. Yet, the final quality of these components isn’t solely dependent on the machining process itself but also on the finishing techniques employed thereafter. Among these, bead blasting stands […]

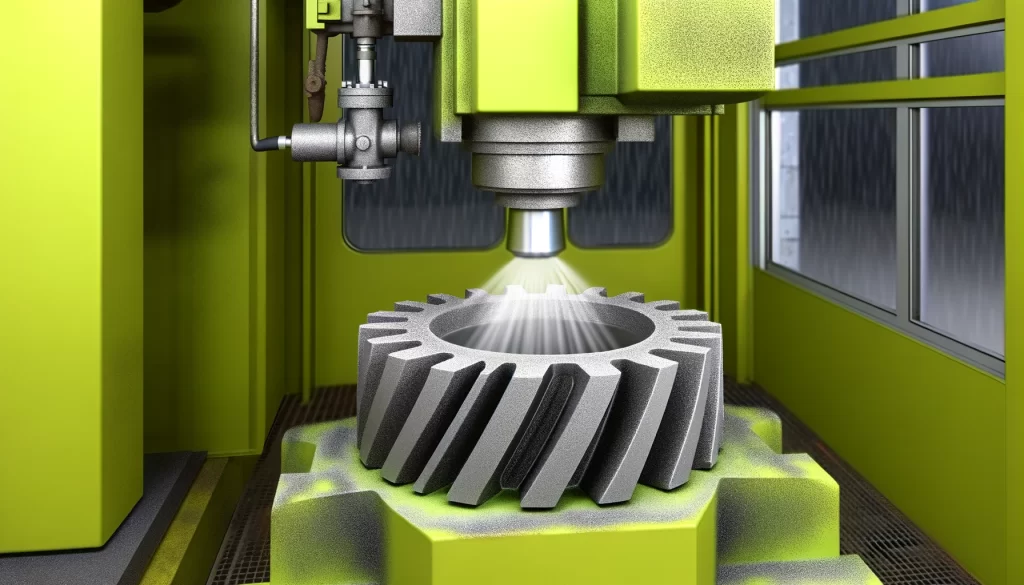

Integrated Application and Case Study of Bead Blasting and Surface Hardening Techniques in CNC Machining

Introduction: Exploring Surface Treatment Technologies in CNC Machining In the evolving landscape of CNC machining, surface treatment technologies like bead blasting and surface hardening are pivotal in enhancing the functionality and aesthetics of machined parts. These processes not only improve the visual appeal but also significantly bolster the durability and performance of components, catering to […]

Precision CNC Machining for the Aerospace Defense Industry

Precision CNC Machining in the Aerospace Defense Industry In modern manufacturing sectors, precision Computer Numerical Control (CNC) machining plays a critical role. It is an automated process that uses pre-programmed software to dictate the motion of factory machinery and tools, facilitating the creation of intricate components with high accuracy. The aerospace defense industry, which is […]