Sheet Metal Fabrication for Automotive Industry

Introduction to Sheet Metal Fabrication in the Automotive Industry Sheet metal fabrication is a cornerstone process in the automotive industry, essential for constructing vehicle frames, bodies, and components. It involves cutting, bending, and assembling sheets of metal to create precise shapes and structures tailored for specific functions within a car. The significance of this technique […]

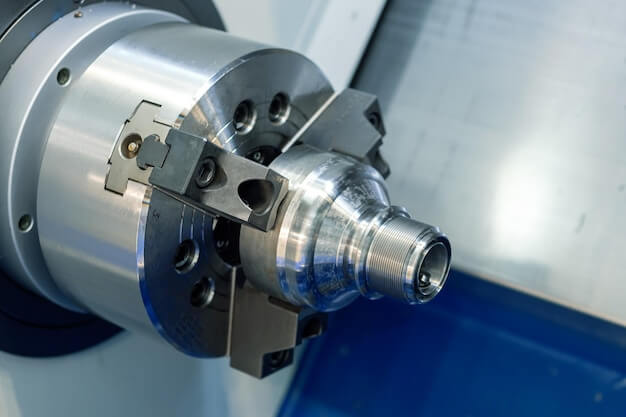

Here are 7 tips for reducing costs in CNC machining.

Introduction to Cost Reduction in CNC Machining CNC machining stands as a pivotal manufacturing process where computer-guided machinery produces complex parts with precision. In an industrial landscape where the push for cost-effectiveness parallels demands for high quality, strategies to trim down expenditures without compromising on output are essential. The upcoming tips highlight how manufacturers can […]

Is titanium magnetic? what is titanium ?

Introduction to Titanium Titanium is a strong, lightweight metal known for its excellent corrosion resistance, high strength-to-weight ratio, and ability to withstand extreme temperatures. These properties make it an essential material in industries such as aerospace, medical, and automotive manufacturing. One of the key advantages of titanium is its resistance to corrosion, which makes it […]

Titanium is used in the production of medical and aerospace instruments.

Unique Properties of Titanium Titanium, a lustrous transition metal with a low density and high strength, stands out for its remarkable resistance to corrosion and ability to withstand extreme temperatures. These unique properties make it an ideal material for demanding engineering applications, particularly in the medical and aerospace sectors. Its biological inertness allows for its […]

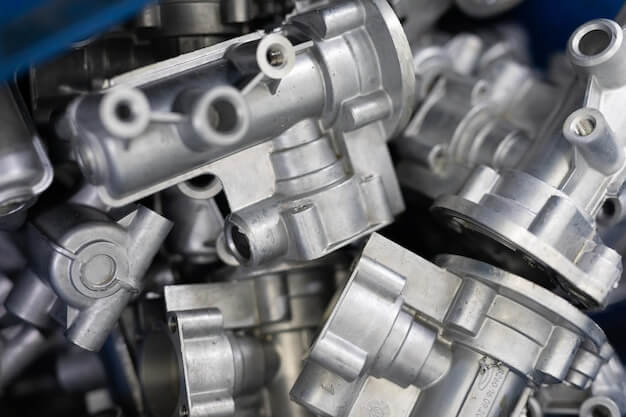

Exploring the World of Non-Ferrous Metals: Characteristics, Applications, and Innovations

Introduction to Non-Ferrous Metals Non-ferrous metals, distinguished by their lack of iron content, are highly valued for their versatility and distinct properties such as resistance to corrosion, high conductivity, and lightweight. These characteristics make them indispensable across a wide array of industries including aerospace, automotive, electronics, and construction. For example, aluminum’s combination of low density […]

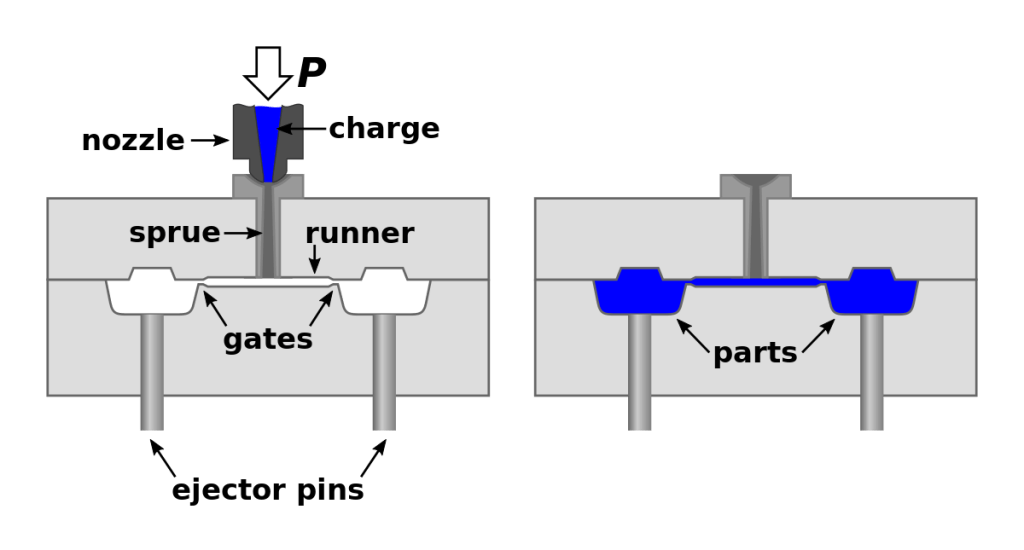

Different types of casting

Introduction to Casting in Manufacturing Casting is a foundational manufacturing process wherein molten material—often metal—is poured into a pre-shaped mold and allowed to solidify, forming a replica of the mold’s internal geometry. This technique enables the production of complex shapes that would be challenging or uneconomical to achieve through other methods. The versatility of casting […]

What Is Tack Welding? Understanding Its Purpose and Importance

Introduction to Tack Welding Tack welding is a preliminary welding process wherein short, intermittent welds are used to hold metal components together before the final welding. This technique is akin to using basting stitches in sewing or temporary pins in woodworking; it maintains alignment and positioning during the construction phase. It’s particularly crucial when dealing […]

What’s Non-Ferrous Metal? In-Depth Overview

Introduction to Non-Ferrous Metals Non-ferrous metals are a broad category of metallic elements and alloys that do not contain iron in appreciable amounts. The absence of iron signifies that they are typically more resistant to corrosion and rust, which makes them ideally suited for applications where longevity and minimal maintenance are desirable. These metals are […]

Alloy steel vs stainless steel

Introduction to Alloy Steel and Stainless Steel An alloy is a combination of metals or a metal mixed with one or more elements, engineered to enhance material properties such as strength, durability, corrosion resistance, and much more. These improved characteristics are pivotal in material science where the performance of materials under various conditions is paramount. […]

Brass vs. Bronze: Unveiling the Superior Metal for CNC Machining

Introduction CNC machining stands for Computer Numerical Control machining, a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technique is pivotal for creating intricate parts with high precision across various industries. Selecting an appropriate material is crucial in CNC machining because it influences the efficiency of the production […]

Aerospace CNC Machining: Precision Engineering for the Skies

CNC (Computer Numerical Control) machining stands as a cornerstone in the production of aerospace components, where its application spells the difference between success and catastrophic failure. In an industry that demands absolute precision, CNC machining provides the ability to produce parts with extremely tight tolerances, often down to micrometer-level accuracy. This is not just beneficial […]

what is insert molding

Insert molding is a manufacturing technique where components, often metal parts, are placed into a mold and encapsulated by molten plastic to create a final composite piece with enhanced functionality. This process differs markedly from traditional injection molding, where preformed parts are not typically incorporated into the molded article. The benefits of insert molding include […]