Titanium Grade 5 vs. Grade 23 in CNC Machining: Which is the Superior Choice?

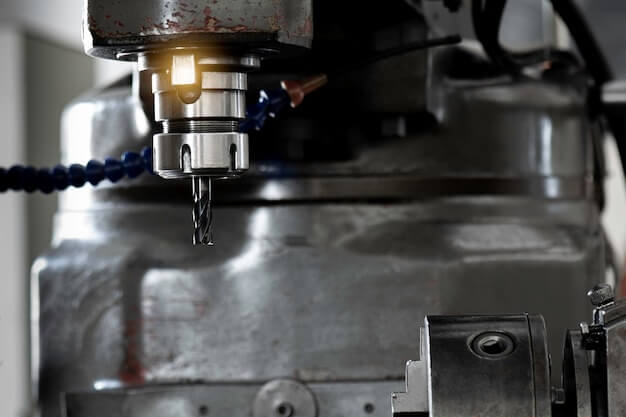

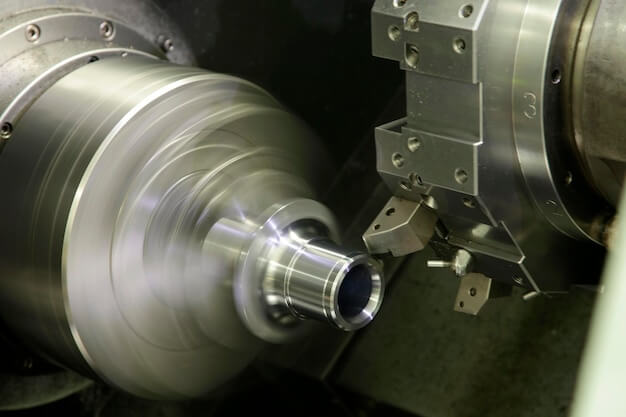

Introduction: Understanding Titanium Grades and Their Importance in CNC Machining Titanium, a metallic element well-known for its high strength and low weight, is categorized into different grades based on its chemical composition. Two of the popularly used titanium grades in Computer Numerical Control (CNC) machining are Grade 5 and Grade 23. These grades offer varied […]

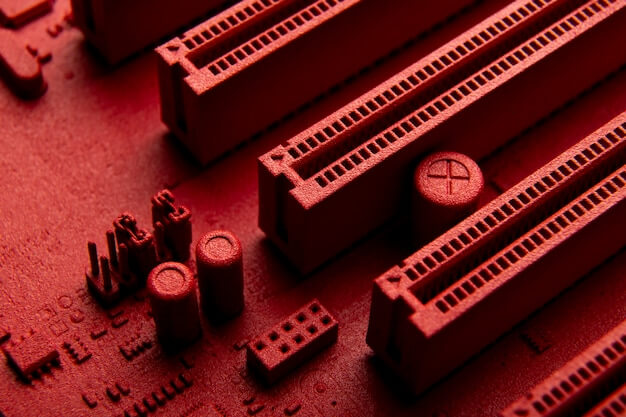

Is Copper the Right Choice for Electrical Component CNC Machining? A Detailed Analysis

CNC Machining of Electrical Components Utilizing Copper In the field of electrical engineering, Computer Numerical Control (CNC) machining plays an integral role, particularly in the development and manufacturing of electrical components. CNC machining is a precise, automated process that involves creation or modification of parts using computer programming to control machine tools, resulting in highly […]

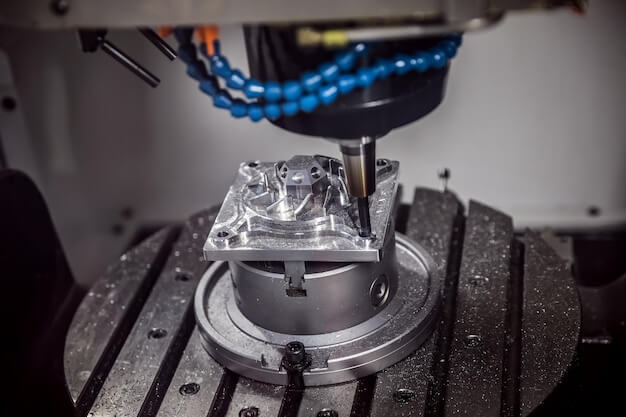

Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate control over process variables such as speed and position. One essential component used in CNC machining is ceramic tooling. Despite its multiple advantages like superior […]

Lead-Free Brass in CNC Machining: Pros, Cons, and Comparisons?

Introduction to Lead-free Brass in CNC Machining CNC (Computer Numerical Control) machining, a prevalent method in the manufacturing sector, uses pre-programmed software to control the movement of factory machinery and tools. This process enables the production of complex three-dimensional parts with a high level of precision. In recent years, there has been a shift towards […]

Choosing Between Zinc and Aluminum Alloys for CNC Machining: Cost-Effectiveness and Performance?

CNC Machining and Zinc & Aluminum Alloys: An Overview Computer Numerical Control (CNC) machining is a crucial process used in the manufacturing sector that entails utilizing pre-programmed computer software dictating the machinery’s movements—effectively controlling a range of machineries from grinders, mills to lathes. This level of automation enables high precision, complex parts production more accurately […]

The Viability of Magnesium Alloys in Lightweight CNC Machined Components: Benefits and Challenges?

Introduction to Magnesium Alloys and CNC Machining Magnesium alloys, due to their lightweight nature coupled with superior mechanical properties, have been gaining prominence in various manufacturing industries. In particular, the use of these alloys in Computer Numerical Control (CNC) machining—a computer-aided process enabling precise control of a variety of complex machinery—has emerged as a leading […]

Exploring the Potential of Inconel in High-Temperature CNC Applications: Is It Worth the Investment?

Exploring the Potential of Inconel in High-Temperature CNC Applications In manufacturing industries, one material that has garnered significant attention for its high-temperature properties is Inconel. This alloy, primarily made up of Nickel and Chromium, exhibits excellent resistance against oxidation and corrosion, even at extremely high temperatures. Its outstanding strength and toughness make it a suitable […]

CNC Machining: Aluminum 2024 vs. 6063 – Which Alloy Performs Better?

Introduction: Aluminum 2024 vs. 6063 Alloys in CNC Machining The process of CNC machining requires careful selection of the appropriate material to ensure optimized performance and product longevity. Key among these considerations are aluminum alloys, specifically 2024 and 6063. The 2024 alloy, composed mostly of aluminum, copper, manganese and small percentages of other compounds, is […]

CNC Machining for Aerospace: Titanium vs. Aluminum Alloys – A Critical Comparison?

CNC Machining for Aerospace: Titanium vs. Aluminum Alloys In the world of aerospace engineering, Computer Numerical Control (CNC) machining plays a pivotal role in manufacturing high-precision components needed for modern aircraft. Using this technology provides accuracy and efficiency that manual operations cannot match. Two widely adopted materials in this industry are titanium and aluminum alloys. […]

The Role of Magnesium Alloys in Reducing Weight for Automotive CNC Machined Parts?

The Importance of Weight Reduction in Automotive Manufacturing and the Role of CNC Machining In automotive manufacturing, weight reduction stands as a pivotal factor influencing fuel efficiency and performance. Lighter vehicles facilitate improved mileage and acceleration along with decreased greenhouse gas emission, which makes it an eco-friendly solution. One essential technique that has emerged to […]

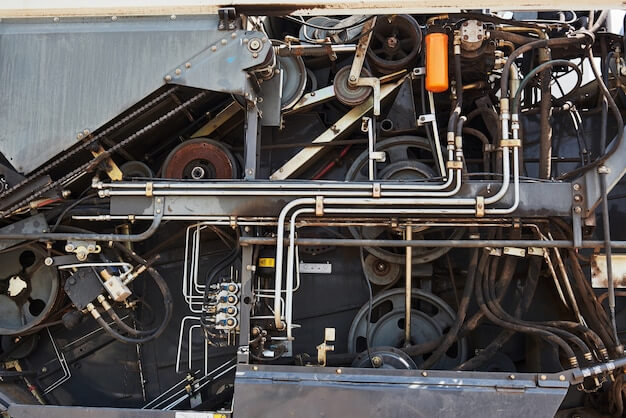

CNC Machining in the Energy Sector: Selecting Materials for Wear Resistance and Longevity

Introduction to CNC Machining in the Energy Sector CNC machining, an acronym for Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory machinery. This technology can manipulate 3D cutting tasks with exceptional precision and enables automatic control of machining tools such as mills, lathes, grinders, and routers. […]

The Role of Titanium in CNC Machining: Benefits and Challenges Explained

Introduction: CNC Machining and the Role of Titanium In the realm of Computer Numerical Control (CNC) machining, each metal utilized possesses distinctive characteristics that cater to specific applications. An essential player in this diverse matrix is Titanium – a high-strength, lightweight metal known for its exceptional corrosion resistance. Often favored in industries such as aerospace […]