Material Choices for High-Volume CNC Machining: Balancing Cost and Performance

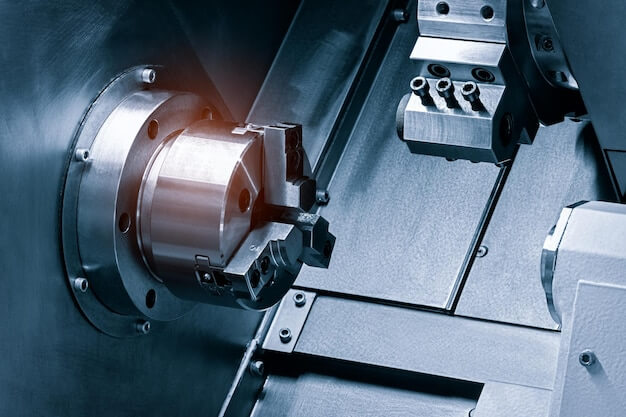

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, offering precision and repeatability that are unmatched by manual processes. At its core, CNC (Computer Numerical Control) machining involves the use of computers to control machine tools, which shape and form materials into desired parts. The challenge often faced in this field […]

The Evolution of CNC Machining: 3D Printing Metals vs. Traditional Machining Materials

Introduction to CNC Machining and 3D Printing CNC machining and 3D printing stand as pivotal technologies in the manufacturing sector, each playing a unique role in how objects are created. CNC (Computer Numerical Control) machining is a process where pre-programmed computer software dictates the movement of factory tools and machinery, allowing for the precise cutting, […]

Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the use of various materials, with traditional alloys and innovative smart alloys, such as shape memory metals, playing pivotal roles. Traditional alloys have been the backbone […]

Reducing Manufacturing Costs with Multi-Material CNC Machining Strategies

Introduction to Manufacturing Costs and CNC Machining Solutions Manufacturing costs significantly impact businesses, encompassing expenses related to materials, labor, and operations. These costs determine the final price of products, affecting competitiveness and profitability. CNC machining emerges as a strategic solution to reduce these costs. This advanced manufacturing technique offers precision and efficiency by automating the […]

Evaluating the Use of Beryllium Copper in CNC Machining for Aerospace Applications: Is It Safe and Effective?

Introduction: Beryllium Copper’s Role in CNC Machining for Aerospace Applications The advanced manufacturing industry, especially aerospace where safety and effectiveness are of prime importance, heavily relies on robust materials to meet the stringent application requirements. One of these materials is Beryllium Copper (BeCu), predominantly used in Computer Numerical Control (CNC) machining due to its unique […]

The Evolution of CNC Machining: From Aluminum to Composite Materials

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to initiate and manipulate machine tools, such as lathes, mills and grinders. With the ability to interpret designs generated by Computer-Aided Design (CAD) software, CNC machines perform various tasks, including drilling, cutting, or shaping materials with extreme precision, […]

Anodized vs. Non-Anodized Aluminum: Which is Better for CNC Machining?

Introduction to CNC Machining and Material Selection CNC Machining, or Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This method can be employed for managing a variety of complex machinery from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting […]

CNC Machining for Aerospace Applications: The Advantages of Superalloys Over Aluminum

Introduction to CNC Machining in Aerospace CNC (Computer Numerical Control) machining stands as a pivotal technology in the aerospace sector, enabling the precise fabrication of components. This method employs computerized controls and machine tools to remove layers of material from a stock piece, thus shaping the desired part. Its significance in aerospace applications cannot be […]

Zirconium vs. Titanium: Comparing CNC Machinability and Corrosion Resistance?

CNC Machinability and Corrosion Resistance: Zirconium vs Titanium The manufacturing industry often has to juggle a plethora of considerations while selecting materials for product manufacture. Top among these are two properties; CNC machinability and corrosion resistance. CNC (Computer Numerical Control) machinability refers to the ease with which a material can be shaped using automated machining […]

Zinc Alloys in CNC Machining: Benefits and Limitations

Introduction – CNC Machining and Zinc Alloys Computer Numerical Control (CNC) machining is a highly precise manufacturing process widely utilized in various industries to create complex parts. It makes use of pre-programmed computer software that dictates the movement of machinery, which can cut, bore, drill or produce intricate shapes with incredible accuracy. One of the […]

The Significance of Thermal Expansion in CNC Machining Materials

Introduction to CNC Machining and Thermal Expansion In the realm of manufacturing, Computer Numerical Control (CNC) machining stands as a modern innovation that utilizes computer programming in controlling machine tools, markedly increasing efficiency and precision. In a nutshell, these complex machines interpret designs generated by special software, then carry out the requisite operations on the […]

CNC Machining Brass vs. Bronze: Cost, Properties, and Applications Showdown?

Introduction to CNC Machining Brass vs. Bronze: Cost, Properties, and Applications Showdown? In this article, we delve into the debate between brass and bronze machining for an important manufacturing process known as CNC (Computer Numerical Control) machining. The write-up will explore various factors such as cost-effectiveness, properties of both metals, and their diverse applications in […]