Zinc Alloy vs. Aluminum for Die Casting: Which Material Wins?

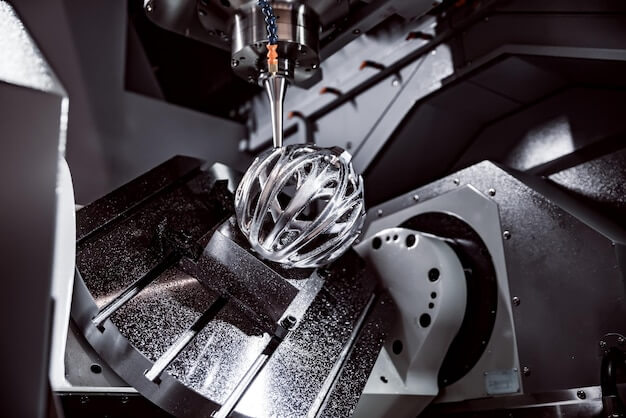

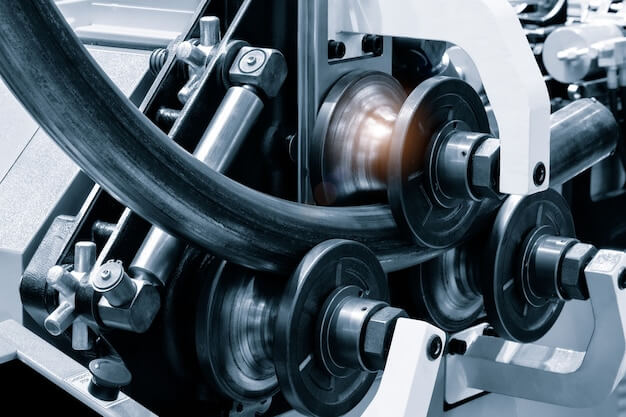

Introduction to Die Casting and Material Selection Die casting is a well-renowned manufacturing process used in the production of various intricate metal parts, where molten metal is forced into a die cavity under high pressure. At its core, it’s about shaping the metal into the desired configuration, by using a customized mold created based on […]

The Role of Alloy 6061 vs. 2024 Aluminum in CNC Aerospace Components: Which is More Efficient?

Introduction to CNC Aerospace Components and Aluminum Alloys 6061 & 2024 CNC (Computer Numerical Control) aerospace components are critical in the aviation industry, primarily attributed to their precision, reliability, and efficient performance. These parts are designed using computer-controlled machines ensuring accurate measurements that align with the stringent requirements of aerospace applications. Quite significantly, specific aluminum […]

The Impact of Surface Finish in CNC Machining: Aluminum vs. Stainless Steel?

Introduction to CNC Machining and Surface Finish Importance CNC machining, or Computer Numerical Control machining, is a manufacturing process involving pre-programmed computer software that maneuvers factory machinery and tools. A significant feature of this technique is its ability to control a range of complex machinery, from grinders to mills and routers – with precision, speed, […]

PEEK Plastic in CNC Machining: Is It a Viable Alternative to Metals for High-Performance Parts?

Introduction to PEEK Plastic and CNC Machining The realm of material science welcomes a game-changing contender, popularly known as PEEK (Polyether Ether Ketone) plastic. A high-performance thermoplastic, PEEK boasts remarkable mechanical properties such as high-temperature stability, excellent chemical resistance, superior strength, stiffness and durability. It provides an edge for industries that necessitate robust materials with […]

Bronze vs. Brass in CNC Machining: Properties, Uses, and Selection Criteria

Introduction to CNC Machining and Importance of Metals CNC machining, or Computer Numeric Control machining, is a commonly utilized method in the manufacturing sector that involves the use of computers to control machine tools. These tools can range from lathes, mills, routers, and grinders. This technology, while advanced, simplifies complex processes which would otherwise require […]

Material Flexibility in CNC Machining: Engineering Soft Materials for Complex Parts

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, offering precision and repeatability that are unmatched by manual processes. At its core, CNC (Computer Numerical Control) machining involves the use of computers to control machine tools, which can shape and design parts with high accuracy. The importance of CNC machining in […]

Enhancing the Mechanical Properties of CNC Machined Parts through Material Blending

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated production of complex parts. This process relies on computerized controls and machine tools to remove layers from a solid block of material, thus shaping the desired part. The significance of CNC machining lies in […]

Thermal Management in CNC Machining: Selecting Materials for Heat Dissipation

Introduction to CNC Machining and Thermal Management CNC machining stands as a cornerstone in modern manufacturing, utilizing computer numerical control to operate machine tools with high precision. This process is pivotal for creating intricate parts with tight tolerances across various industries. A critical aspect often overlooked is thermal management within CNC machining processes. Effective thermal […]

Leveraging the Strength and Lightness of Carbon Fiber Materials in CNC Machining for Automotive Racing Parts

Carbon Fiber Materials and CNC Machining in Automotive Racing Parts Manufacturing Carbon fiber materials, often regarded as a pinnacle of materials due to their impressive strength-to-weight ratio, are crucial in the realm of automotive racing parts manufacturing. These materials boast excellent rigidity and fatigue resistance, making them exceptional for high-stress environments found in motor sports. […]

Inconel vs. Monel for CNC Machining: Understanding the Differences and Applications?

Inconel vs. Monel: Definitions and Primary Uses In the realm of CNC machining, two materials that are often compared due to their unique properties are Inconel and Monel. Inconel is a class of superalloys made predominantly from nickel and chromium. This combination results in formidable resistance to extreme temperatures and corrosive mediums, making Inconel a […]

The Pros and Cons of Using Copper Alloys in CNC Machining Projects

Introduction to Copper Alloys and CNC Machining In the realm of materials suitable for manufacturing operations, copper alloys have emerged as a viable contender. Noted for their excellent thermal conductivity, corrosion resistance, and mechanical strength, they form an integral part in producing various components through a process known as Computer Numerical Control (CNC) machining. CNC […]

The Impact of Surface Finish in CNC Machining: Aluminum vs. Stainless Steel?

Introduction to CNC Machining and Surface Finish with a Focus on Aluminum and Stainless Steel Computer Numerical Control (CNC) machining is a vital manufacturing process used in creating complex parts out of various materials. It employs computer-programmed machines to execute precise movements for cutting, shaping, or forming these materials. A crucial aspect of this process […]