Can Precision CNC Machining Compensate for Material Weaknesses in High-Stress Applications?

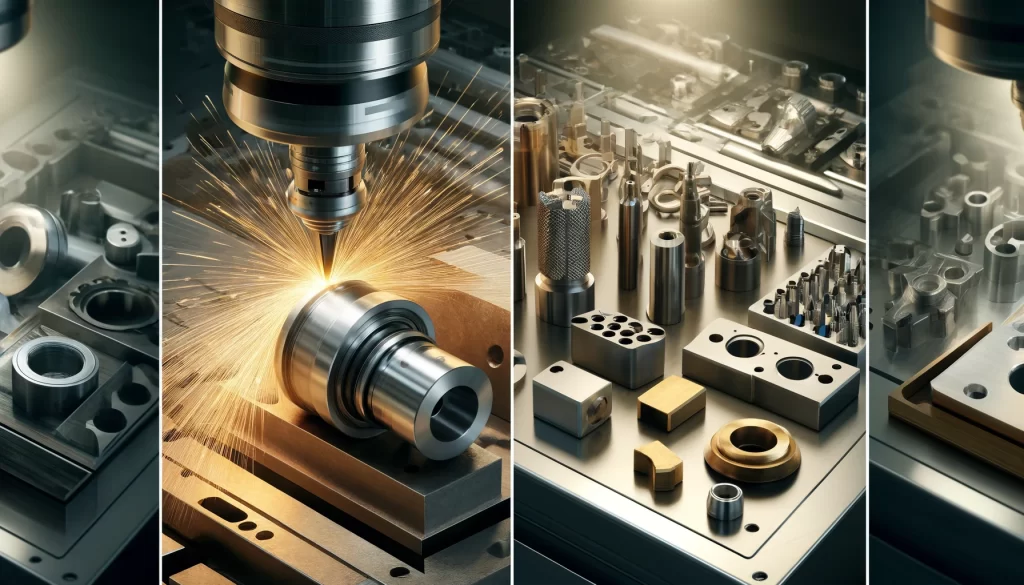

The Role of CNC Machining in Material Enhancement In engineering applications where materials are subjected to high stress, the choice and treatment of materials are crucial for the integrity and longevity of the final product. Precision CNC machining emerges as a transformative technology that not only shapes materials but also enhances their properties. This process […]

Aluminum vs. Brass: Which Metal Offers Better Precision in CNC Lathe Machining?

Introduction to CNC Lathe Machining CNC lathe machining, or Computer Numerical Control lathe machining, is a modern method of metal fabrication that allows for the precision crafting of complex parts and components. This computer-controlled process manipulates cutting tools to shape material as determined by inputted instructions, drawing from digital files or programmed data for exactness […]

Why is Brass Preferred for Precision CNC Machining in Food Automation Equipment?

Why Choose Brass for CNC Machining in Food Automation? Brass, with its remarkable machinability and corrosion resistance, stands out as an ideal material for food automation equipment. Used widely in gears, valves, and fittings within food processing machinery, brass not only offers durability but also safety, due to its antimicrobial properties. This introduction sets the […]

Online CNC Machining Services for Aluminum Parts: Cost-Effective Solutions for Low Volume Production?

Introduction to CNC Machining and Its Application in Manufacturing Aluminum Parts Computer Numerical Control (CNC) machining is a widely applied manufacturing process that uses pre-programmed computer software to dictate the movement of factory machines and tools. This technology-driven process has revolutionized the manufacturing industry, particularly in parts production, such as aluminum components. The flexibility and […]

How to Optimize Feed Rates and Speeds for CNC Machining Aluminum Parts?

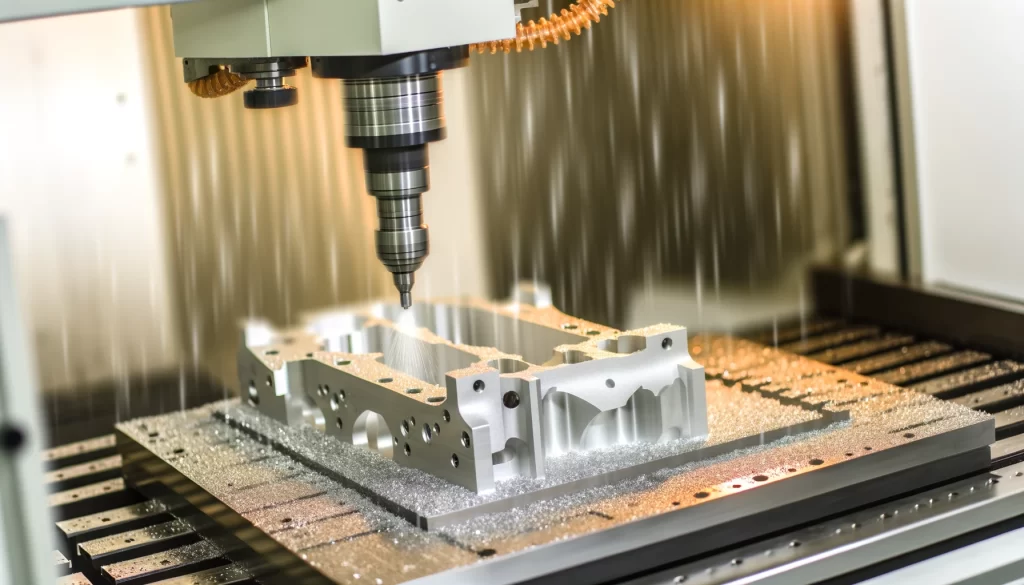

Introduction to CNC Machining of Aluminum CNC machining of aluminum is a critical process in various industries, including aerospace, automotive, and consumer electronics, where precision and efficiency are paramount. Understanding how to optimize the feed rates and speeds during the machining process is essential to achieving high-quality parts while minimizing waste and operational costs. This […]

How to Minimize Tool Chatter in precision CNC machining of Aluminum Parts?

Introduction to Tool Chatter in CNC Machining of Aluminum Tool chatter in CNC machining significantly undermines the quality and precision of machined aluminum parts. This phenomenon, characterized by oscillations and vibrations, arises due to the interaction between the cutting tool and the workpiece. Aluminum, with its relatively low modulus of elasticity and high ductility, is […]

What Are the Thermal Management Challenges in CNC Machining parts of Aluminum?

Introduction to Thermal Management in CNC Machining In the realm of CNC machining parts, thermal management is a pivotal aspect that significantly influences the quality, precision, and efficiency of the machining process, especially when dealing with aluminum parts. Aluminum, due to its high thermal conductivity and lower melting point relative to other metals, presents unique […]

What CNC Machining Techniques Are Best for Aluminum Parts in Food Automation?

Introduction to CNC Machining of Aluminum for Food Automation In the realm of food automation, precision and reliability are paramount. Aluminum parts play a critical role due to their resilience and lightweight nature, which are essential in high-speed food processing environments. CNC machining offers unparalleled precision, making it indispensable for producing complex aluminum parts that […]

How to Overcome Corrosion Issues in Aluminum CNC Machined Parts for Food Machinery?

Introduction to Corrosion in Aluminum CNC Machined Parts Corrosion of aluminum parts in food machinery presents a significant challenge to manufacturers, as it not only compromises the integrity and functionality of the machinery but also raises concerns about food safety and product longevity. Aluminum, while known for its lightweight and strength, is susceptible to corrosion, […]

How Does CNC Machining Optimize Aluminum Parts for Food Automation Machinery?

Introduction to CNC Machining of Aluminum for Food Automation Machinery CNC machining stands as a cornerstone in the manufacturing of precision parts, particularly when it comes to aluminum—a metal revered for its lightweight and robust nature. In the realm of food automation machinery, the exactness and reliability of CNC machining are not just beneficial but […]

Can Advanced CNC Techniques Reduce Waste in Aluminum Machining?

Introduction to Waste Reduction in CNC Machining In the competitive landscape of modern manufacturing, reducing waste is not just an environmental imperative but a significant economic necessity. For industries that rely heavily on CNC machining, like automotive and aerospace, the drive towards sustainability has prompted a reevaluation of production processes, particularly in the machining of […]

How Does Precision CNC Machining Overcome Challenges with Aluminum?

Introduction to Aluminum in Precision CNC Machining Aluminum is renowned for its lightweight yet strong properties, making it a preferred material in industries ranging from aerospace to electronics. Its adaptability and excellent thermal and electrical conductivity also contribute to its widespread use. However, aluminum presents unique challenges when subjected to precision CNC machining processes. These […]