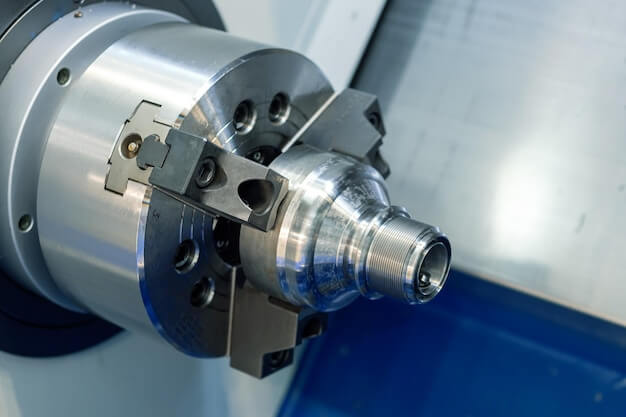

How to Optimize CNC Machine Settings for High-Quality Dental Implants Production?

Introduction: The Importance of Precision in CNC Machining for Dental Implants In the world of medical device manufacturing, precision is not merely a goal; it’s a requirement. CNC (Computer Numerical Control) machining stands out as a pivotal technology in the production of dental implants, where each specification must be meticulously met to ensure the implants […]

Using Super Duplex Stainless Steel in CNC Machining: Advantages for High-Corrosion Resistance Parts

Introduction to Super Duplex Stainless Steel and CNC Machining Super duplex stainless steel, a prominent material in the manufacturing industry, possesses an optimized balance of properties that make it desirable for numerous demanding applications. Characterised by its dual phase structure – containing roughly equal parts of ferrite and austenite – super duplex stainless steels exhibit […]

How to Select the Most Suitable Machining Parameters for Complex Shape Parts in CNC?

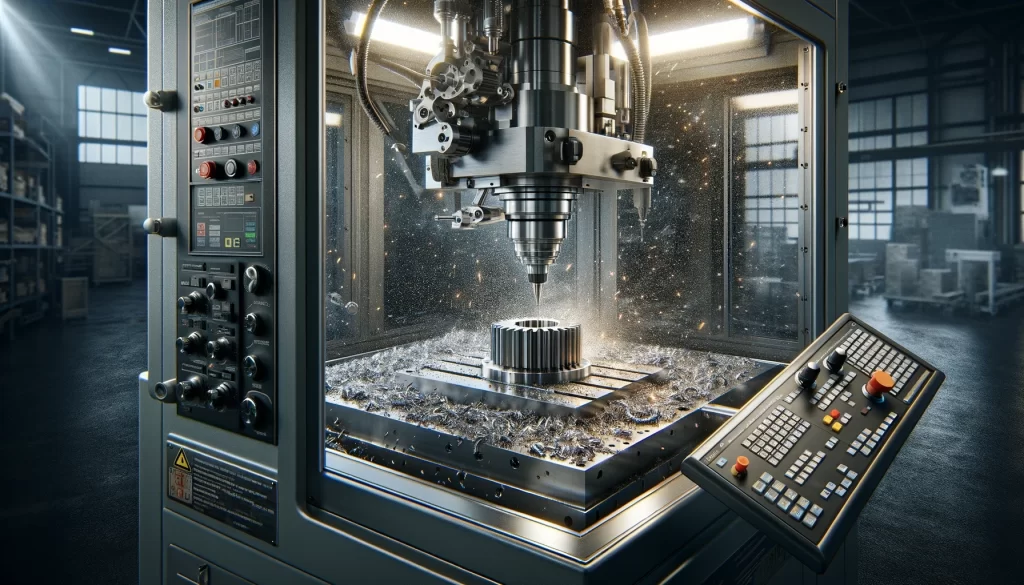

Introduction to CNC Machining of Complex Shapes CNC machining has revolutionized the manufacturing industry by enabling the production of complex shapes with high precision and efficiency. This technology utilizes computerized controls and machine tools to remove layers of material from a stock piece, known as the workpiece, to produce a custom-designed part or product. This […]

Ceramic Composite Materials in CNC Machining: Are They the Future of Aerospace Components?

Introduction to CNC Machining and Ceramic Composite Materials CNC (Computer Numerical Control) machining is a pivotal manufacturing process in the aerospace industry. It’s characterized by automated control of machine tools through software inputs, ensuring precision-engineering of components that are critical for constructing aircrafts and their engines. This meticulous approach enhances accuracy, quality control and contributes […]

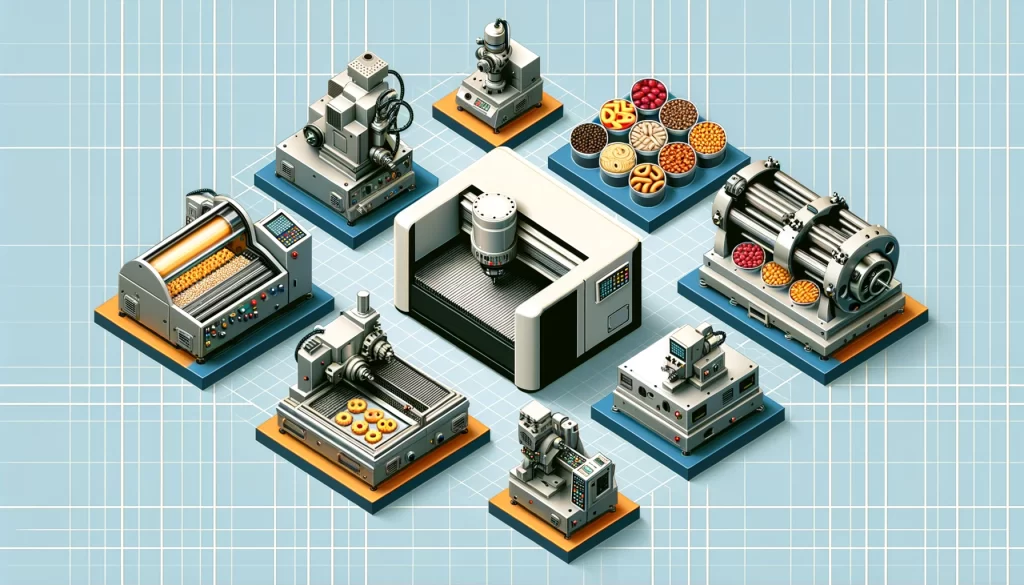

How Are Multi-Head Nozzles for Food Filling Packaging Made Using CNC Machining?

Introduction to CNC Machining and Multi-Head Nozzles CNC (Computer Numerical Control) machining is a process used extensively in manufacturing that involves the use of computers to control machine tools. Multi-head nozzles, particularly used in food filling packaging, are CNC machining parts;and they are complex components that require high precision during production. This article explores the […]

How Do CNC Machining Parts Help Food Automation Machinery Comply with Strict Food Safety Regulations?

Introduction CNC (Computer Numerical Control) machining is a cornerstone of modern manufacturing, providing unparalleled precision and efficiency. In the context of food automation machinery, CNC machining parts play a critical role in ensuring that equipment meets stringent food safety standards. These standards are crucial for preventing contamination and ensuring the quality and safety of food […]

Ceramics in CNC: Zirconia vs. Alumina – Which Offers Superior Durability?

Ceramics in CNC: Zirconia vs. Alumina In the realm of Computer Numerical Control (CNC), ceramics are widely used due to their exceptional mechanical properties, including durability and resistance to wear. Specifically, zirconia and alumina have become standout materials in various manufacturing contexts. Both constitute advanced ceramic materials that afford enhanced performance capabilities compared to traditional […]

Is Machining with Titanium Worth the Cost for Aerospace Applications?

Machining with Titanium in Aerospace Applications The manufacturing process that involves the use of titanium, particularly in aerospace applications, is referred to as machining with titanium. This method has been increasingly adopted due to titanium’s unique properties such as its strong resistance to corrosion, high heat performance, and exceptional strength-to-weight ratio. These characteristics make it […]

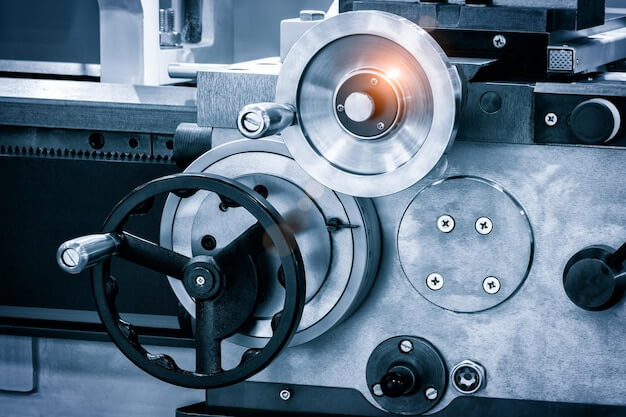

How Are Drive Rollers for Food Conveyors Designed and Manufactured with Precision CNC Machining?

Precision CNC Machining for Food Conveyor Components Computer Numerical Control (CNC) machining stands as a cornerstone technology in modern manufacturing, offering unparalleled precision and efficiency. In the context of the food industry, CNC machining takes on an essential role, especially in the fabrication of critical components like drive rollers for food conveyors. These components are […]

How to Choose the Right Coatings to Protect Food Machinery in Precision CNC Machining?

Introduction to Precision CNC Machining for Food Machinery Precision CNC machining stands as a cornerstone in modern manufacturing, offering unparalleled accuracy and repeatability essential for the food machinery sector. In this industry, the machinery must not only operate to exact specifications but also meet rigorous safety and hygiene standards. Protective coatings play a pivotal role […]

How to Choose the Right Surface Finish Techniques for Precision CNC Machining of Food Automation Machinery?

Surface Finish in Precision CNC machining Precision CNC machining plays a pivotal role in manufacturing components for food automation machinery. The surface finish of these components is crucial not only for the machinery’s performance but also for its compliance with strict food safety standards. This article explores the essential factors for selecting the most appropriate […]

What Materials Are Best Suited for CNC Machined sprockets in Food Automation Systems?

Selection of Materials for sprockets in Food Automation Systems The rapidly evolving field of food automation demands components that combine precision, efficiency, and unwavering adherence to safety standards. CNC machined sprockets, integral to the movement and functionality of food processing equipment, must be manufactured with materials that not only endure the mechanical rigors of operation […]