CNC Machining with Plastics: POM vs. PEEK – Which is More Efficient?

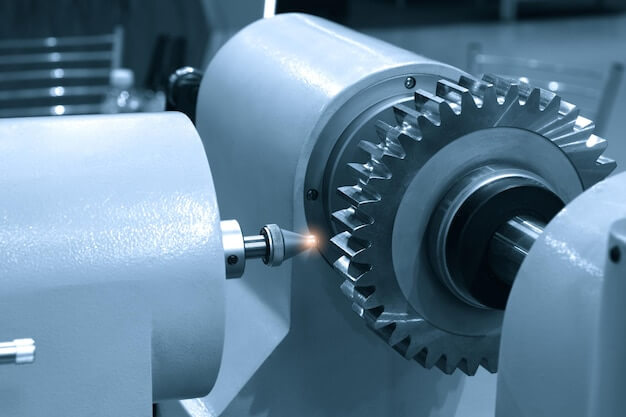

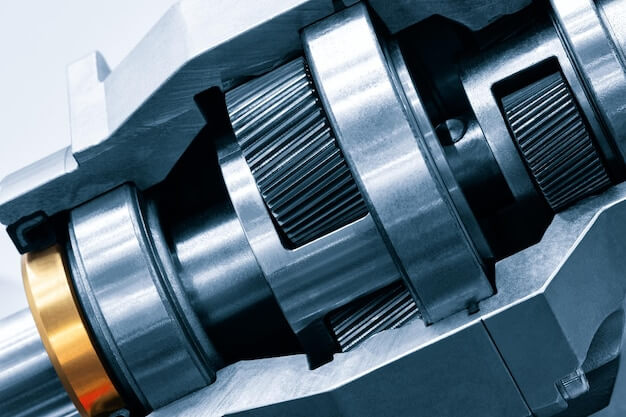

CNC Machining in Manufacturing and the Utilization of Plastics In today’s advanced manufacturing industry, CNC (Computer Numerical Control) machining continues to play an integral role. This technology helps in creating parts and pieces with a high level of precision and consistency, making it indispensable for industries demanding accuracy such as aerospace, automotive, medical, and more. […]

PEEK Plastic in CNC Machining: Is It a Viable Alternative to Metals for High-Performance Parts?

Introduction to PEEK Plastic and CNC Machining The realm of material science welcomes a game-changing contender, popularly known as PEEK (Polyether Ether Ketone) plastic. A high-performance thermoplastic, PEEK boasts remarkable mechanical properties such as high-temperature stability, excellent chemical resistance, superior strength, stiffness and durability. It provides an edge for industries that necessitate robust materials with […]

PEEK vs. PEI in CNC Machining: Which Offers Better Performance for Engineering Applications?

Introduction to CNC Machining and the Materials PEEK and PEI CNC machining is an automated manufacturing technology that involves computer controls directing machinery in performing material cutting operations to produce specific parts. Its versatility, precision, and ability to replicate designs seamlessly has made it an essential component of various industries including automotive, aerospace, and medical […]

PEEK vs. PEI (Ultem) in CNC Machining: A High-Performance Plastics Showdown

Introduction: PEEK vs. PEI (Ultem) in CNC Machining When it comes to high-performance plastics for Computer Numerical Control (CNC) machining, two names often arise – Polyether Ether Ketone (PEEK) and Polyetherimide (Ultem). Within the realm of manufacturing industries, making the right choice between these materials can greatly influence cost-efficiency, product quality, and performance. PEEK typically […]

CNC Machining Precision: How Material Choice Affects Tolerance and Accuracy

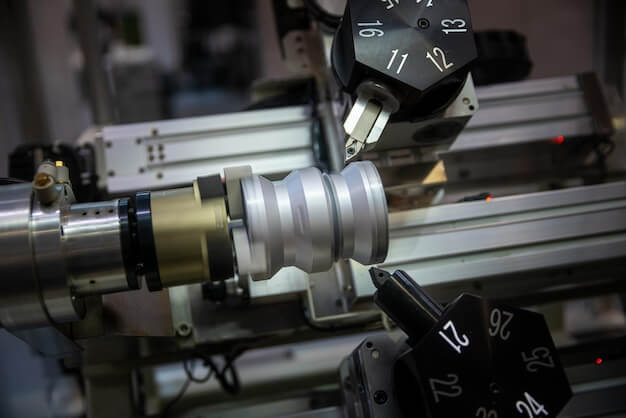

Introduction to CNC Machining CNC Machining stands for Computer Numerical Control Machining, a cornerstone in modern manufacturing. This process uses computer-controlled machines to achieve high precision and accuracy in creating parts. It’s pivotal for industries where precision is paramount, such as aerospace, automotive, and medical devices. The essence of CNC machining lies in its ability […]

Cost-Effective CNC Machining: Evaluating Material Choices for Budget-Conscious Projects

Introduction to Cost-Effective CNC Machining CNC (Computer Numerically Controlled) machining is an advanced manufacturing process that uses programmed software to control tools and machinery. In the contemporary production sector, this technology plays a significant role thanks to its ability to create intricate parts with high precision and consistency. For budget-conscious projects, cost-effectiveness becomes paramount. The […]

High-Speed vs. Conventional CNC Milling: Material and Application Considerations

CNC Milling: An Overview of High-Speed vs Conventional Methods Computer Numerical Control (CNC) milling is a machining process that plays an invaluable role in producing intricate parts for various applications. Through the use of computer systems to control and manipulate machine tools, CNC milling allows for precision accuracy in creating complex 3D shapes from solid […]

PEEK vs. ABS: A Guide to Choosing Injection Molding Materials

Introduction to Injection Molding and Material Choices The process of injection molding is a manufacturing technique that shapes plastic or other materials by heating them until they become pliable, and then injecting them into a mold. It’s frequently used for mass-producing objects with the same shape, such as automotive parts, toys, and bottles caps – […]

PEEK vs. ABS: A Guide to Choosing Injection Molding Materials

Understanding the Importance of Material Selection in Injection Molding Injection molding, a prevalent manufacturing method, requires meticulous attention towards selecting the appropriate material. The choice between materials such as PEEK and ABS can significantly impact not only the production process but also the attributes and applications of the final product. Both these thermoplastics have unique […]

SLS vs. SLA Materials: Choosing the Right 3D Printing Technology

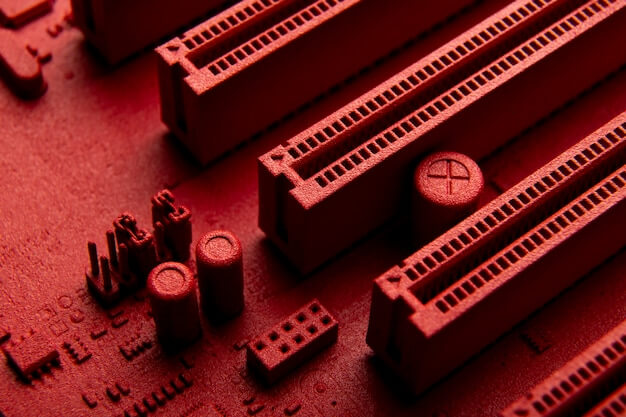

Introduction to 3D Printing Technology and SLS vs SLA Materials In the world of manufacturing, 3D printing technology has emerged as a revolutionary tool with its ability to transform digital designs into physical objects. This procedure functions on an additive principle, assembling layers upon layers to create three-dimensional products. Amongst the multitude of 3D printing […]

The Art of CNC Machining: Aesthetic Materials for Consumer Products

Introduction to CNC Machining and its Aesthetic Significance in Consumer Products CNC Machining, known formally as Computer Numerical Control Machining, serves a significant role in producing consumer products. This technique uses computers to control machine tools for an accurate and efficient production process. The focus of this article touches upon the crucial use of aesthetic […]

Custom CNC Machining for Unique Applications: Exotic Material Options

Introduction to Custom CNC Machining and Exotic Material Options Custom Computer Numerical Control (CNC) machining epitomizes the pinnacle of advanced manufacturing procedures. It enables the transformation of a digital design into a tangible, refined product through precise milling and cutting. The relevance of exotic material options in this field cannot be understated, often marking the […]