Precision CNC Machining for High-End Audio Equipment

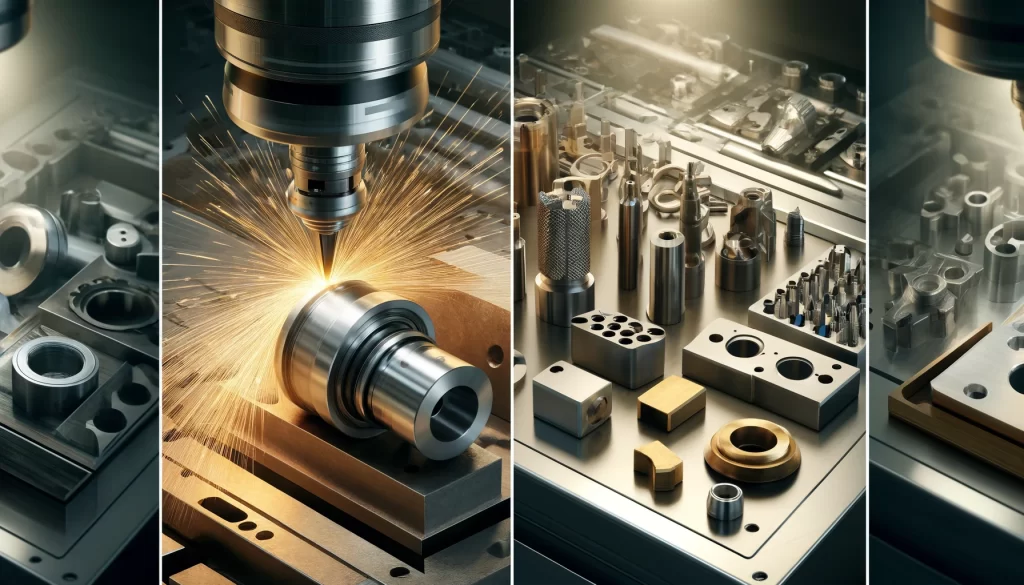

Precision CNC Machining and its Role in High-End Audio Equipment Manufacturing The production of high-end audio equipment relies heavily on precision-driven processes to ensure the best quality sound. One such process is Precision CNC (Computer Numerical Control) machining, which plays an instrumental role. This method involves the use of computers to control machine tools with […]

What Are the Key Challenges in CNC Machining Carbon Steel for Automotive Parts and How Can They Be Overcome?

What Makes Carbon Steel a Challenging Material for CNC Machining? Carbon steel is widely used in the automotive industry due to its strength, durability, and cost-effectiveness. However, it presents several challenges in CNC machining that require careful consideration and specialized techniques to overcome. 1. Hardness and ToughnessCarbon steel’s hardness and toughness are beneficial for the […]

Plastic CNC Machining Services with PEEK for Complex Components

Introduction to Plastic CNC Machining Services with PEEK The field of manufacturing has embraced the revolutionizing technology of Computer Numerical Control (CNC) machining, taking plastic component production to advanced levels. This method employs computer-aided design and manufacturing software for automating machine tools control in a precise manner. One significant material that stands out in this […]

Can Precision CNC Machining Compensate for Material Weaknesses in High-Stress Applications?

The Role of CNC Machining in Material Enhancement In engineering applications where materials are subjected to high stress, the choice and treatment of materials are crucial for the integrity and longevity of the final product. Precision CNC machining emerges as a transformative technology that not only shapes materials but also enhances their properties. This process […]

Why is Brass Preferred for Precision CNC Machining in Food Automation Equipment?

Why Choose Brass for CNC Machining in Food Automation? Brass, with its remarkable machinability and corrosion resistance, stands out as an ideal material for food automation equipment. Used widely in gears, valves, and fittings within food processing machinery, brass not only offers durability but also safety, due to its antimicrobial properties. This introduction sets the […]

Nylon CNC Machining Service for Custom Parts

Nylon is an engineering plastic known for its high strength, wear resistance, and chemical inertness. It possesses excellent mechanical properties and durability, making it widely used in various fields including mechanical parts, automotive components, electronics, and sports equipment.Nylon CNC machining finds extensive applications in automotive parts (e.g., brake system components, transmission parts), mechanical parts (e.g., […]

What Materials Are Best for CNC Machining Food Safe Filling Nozzles?

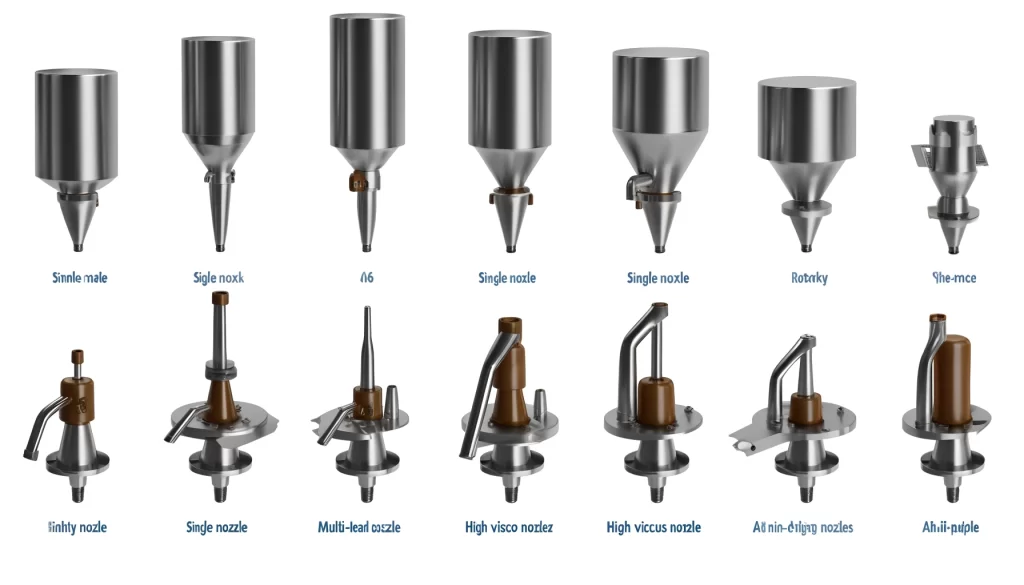

CNC Machining of Food Safe Filling Nozzles CNC (Computer Numerical Control) machining plays a pivotal role in the food processing industry by enabling the production of highly precise and customized components essential for modern food manufacturing. Among these components, the filling nozzle is also cnc machining parts,filling nozzles are critical due to their direct contact […]

Are CNC Machined Filling Nozzles Compatible with All Food Automation Machinery?

Introduction: The Role of CNC Machined Filling Nozzles in Food Automation? CNC (Computer Numerical Control) machining has revolutionized the production of precise and intricate components across various industries, with food automation being one of the significant sectors benefiting from its advancements. And ,among them, the filling nozzles are also CNC machining parts.Filling nozzles, crucial for […]

How Are Multi-Head Nozzles for Food Filling Packaging Made Using CNC Machining?

Introduction to CNC Machining and Multi-Head Nozzles CNC (Computer Numerical Control) machining is a process used extensively in manufacturing that involves the use of computers to control machine tools. Multi-head nozzles, particularly used in food filling packaging, are CNC machining parts;and they are complex components that require high precision during production. This article explores the […]

How Do CNC Machining Parts Help Food Automation Machinery Comply with Strict Food Safety Regulations?

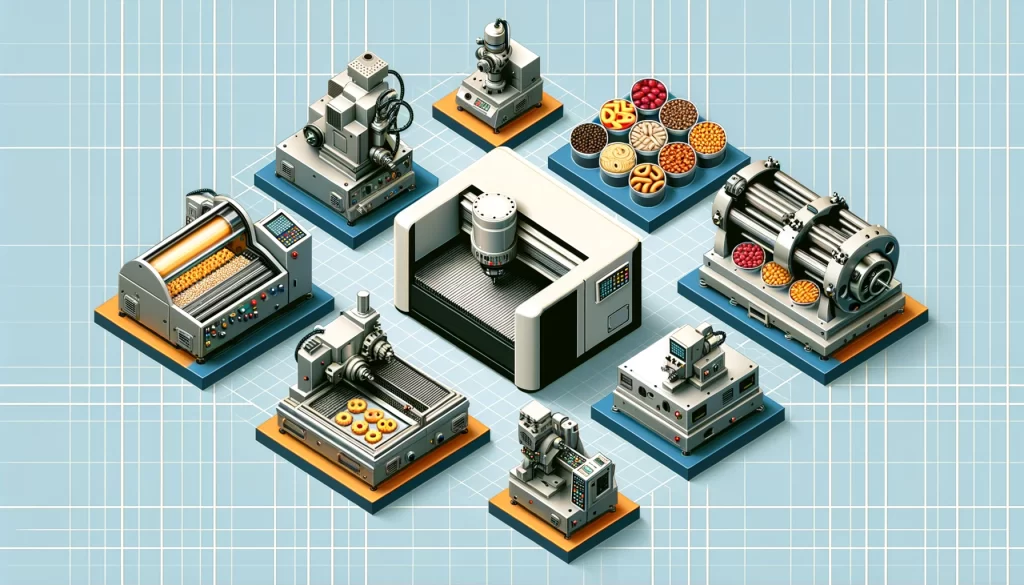

Introduction CNC (Computer Numerical Control) machining is a cornerstone of modern manufacturing, providing unparalleled precision and efficiency. In the context of food automation machinery, CNC machining parts play a critical role in ensuring that equipment meets stringent food safety standards. These standards are crucial for preventing contamination and ensuring the quality and safety of food […]

Ceramics in CNC: Zirconia vs. Alumina – Which Offers Superior Durability?

Ceramics in CNC: Zirconia vs. Alumina In the realm of Computer Numerical Control (CNC), ceramics are widely used due to their exceptional mechanical properties, including durability and resistance to wear. Specifically, zirconia and alumina have become standout materials in various manufacturing contexts. Both constitute advanced ceramic materials that afford enhanced performance capabilities compared to traditional […]

How Are Drive Rollers for Food Conveyors Designed and Manufactured with Precision CNC Machining?

Precision CNC Machining for Food Conveyor Components Computer Numerical Control (CNC) machining stands as a cornerstone technology in modern manufacturing, offering unparalleled precision and efficiency. In the context of the food industry, CNC machining takes on an essential role, especially in the fabrication of critical components like drive rollers for food conveyors. These components are […]