Choosing the Right Material for CNC Machined Prototypes: ABS vs. Polycarbonate

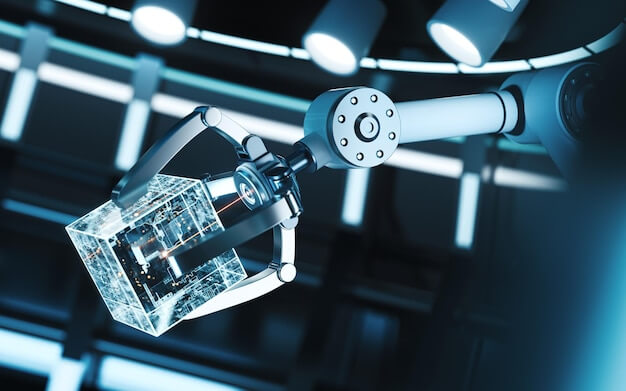

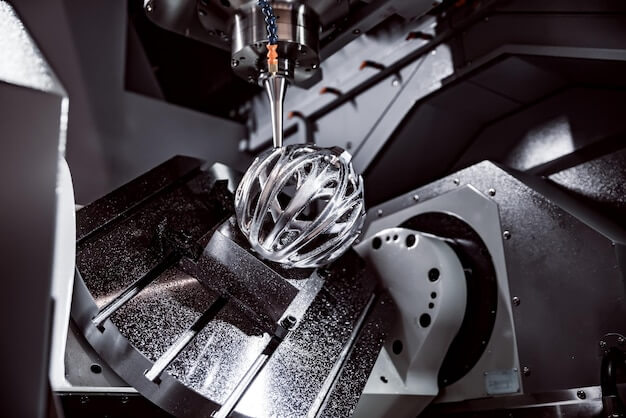

Overview of CNC Machining and Its Importance in Prototyping CNC Machining, short for Computer Numerical Control Machining, is a critical process widely used in the creation of prototypes across various sectors. This digital procedure utilizes computers to control machine tools, allowing for precise productions that are exceedingly close to the final product’s technical design. Due […]

Polypropylene vs. Polyethylene: Understanding the Differences for Injection Molding

Understanding the Basics of Injection Molding and the Role of Plastics The process of injection molding, a prevalent method in manufacturing, involves injecting molten plastic into a mold then letting it cool to create a variety of complex shapes. This technique is heavily relied upon in various industries, ranging from automotive to medical sectors, owing […]

The Role of CNC Machining in Renewable Energy: Material Choices for Durability and Efficiency

Introduction to CNC Machining and its Relevance in Renewable Energy CNC (Computer Numerical Control) machining, a technology rooted in the manufacturing space, involves the use of computers to drive and control machine tools such as lathes, mills, routers, and grinders. This kind of precision-driven operation has found great applicability within the renewable energy industry, which […]

Achieving High Performance in CNC Machined Automotive Parts: Material Selection Guide

Introduction to CNC Machining in the Automotive Industry In the automotive industry, Computer Numerical Control (CNC) machining is a pivotal manufacturing process primarily used for creating complex parts with high precision. This procedure involves pre-programmed computer software dictating movements of the machinery and eliminating possible manual errors. Being able to produce large quantities while maintaining […]

Leveraging the Strength of Tool Steels in CNC Machining: A2 vs. D2 Comparison

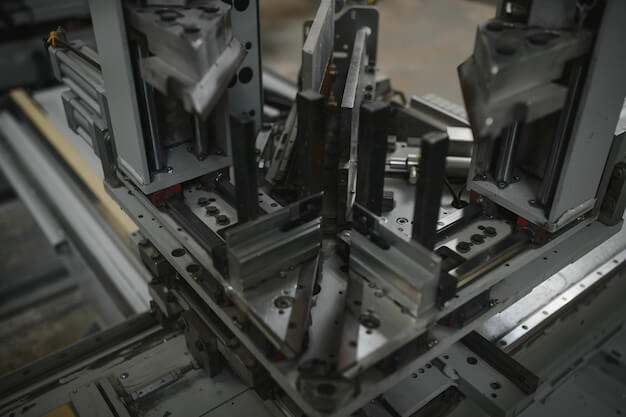

Introduction to Tool Steel and CNC Machining In the vast domain of manufacturing, tool steel is a particular subset of hard metal renowned for its resistance to abrasion, ability to retain shape under heavy loads, and notch toughness. The material properties make it an ideal choice in a wide range of industrial applications including cold […]

Magnesium Alloys: Are They a Viable Alternative to Aluminum in Automotive?Injection Molding Materials Face-Off: Polycarbonate vs. Acrylic

Material Choice Importance in Automotive Manufacturing: Magnesium Alloys vs Aluminum In the world of automotive manufacturing, the choice of materials is instrumental as it affects overall performance, aesthetics, cost-efficiency, and sustainability of vehicles. Recently, magnesium alloys have been put under scrutiny given their potential to serve as a viable alternative to traditional aluminum. As lightweight […]

TPE vs. TPU in 3D Printing: Flexibility, Durability, and Use Cases

Introduction to 3D Printing Using TPE and TPU Materials 3D printing, a revolutionary technology that has transformed multiple industries such as manufacturing, healthcare, and aerospace, is dependent on the choice of materials used. These materials play a crucial role not only in determining print quality but also in influencing the physical characteristics of the printed […]

Improving CNC Machining Accuracy with Material Selection: Thermal Expansion Considerations

Introduction to CNC Machining and Its Correlation with Material Selection In the realm of advanced manufacturing, Computer Numerical Control (CNC) machining stands as a pivotal technique. Simplifying what would otherwise be complex manual work, CNC machines automate design tasks by interpreting 3D instructions from a computer and applying them onto selected raw materials to create […]

Material Selection for CNC Machining Under Extreme Conditions: Heat and Pressure Considerations

CNC Machining and the Importance of Material Selection Computer Numerical Control (CNC) machining, a predominant method in manufacturing industries, involves the use of computers to control machine tools with precision and speed. A key aspect for successful CNC machining is material selection. The choice determines not only the parts’ quality but also significantly impacts the […]

Reducing Manufacturing Costs with Smart Material Choices in CNC Machining

Introduction to CNC Machining CNC machining stands for Computer Numerical Control machining, a cornerstone in modern manufacturing. This process uses computer-controlled machines to shape material into precise parts and components. Its importance lies in its ability to produce complex shapes with high precision, making it indispensable across various industries, from aerospace to consumer electronics. A […]

Exploring the Potential of Smart Materials in Future CNC Machining Processes

Introduction: The Intersection of Smart Materials and CNC Machining Processes Smart materials, also known as intelligent or responsive materials, have the inherent ability to alter their respective physical properties in response to changes within their environment. This capability makes them remarkably suitable for the implementation in a host of industries and operations, including Computer Numerical […]

Hard Milling vs. Soft Milling in CNC: Material Considerations and Strategies

Introduction to Milling in CNC Manufacturing Milling, a fundamental process in Computer Numerical Control (CNC) manufacturing, plays an integral role in the production of diverse components across various industries. This machining method can be defined as a technique that allows machine tools to perform cutting operations on raw material while they’re steered by commands from […]