Magnesium Alloys: Are They a Viable Alternative to Aluminum in Automotive?Injection Molding Materials Face-Off: Polycarbonate vs. Acrylic

Introduction to Automotive Injection Molding Materials The application of different materials in automotive injection molding has been subjected to rigorous debates, particularly between magnesium alloys and aluminum. Both exhibit strong performance characteristics yet depict distinctive differences influencing their selection for specific applications or design requirements within the auto industry. Similarly, another face-off exists within the […]

CNC Machining Materials Deep Dive: Acrylic vs. Polycarbonate for Transparent Parts

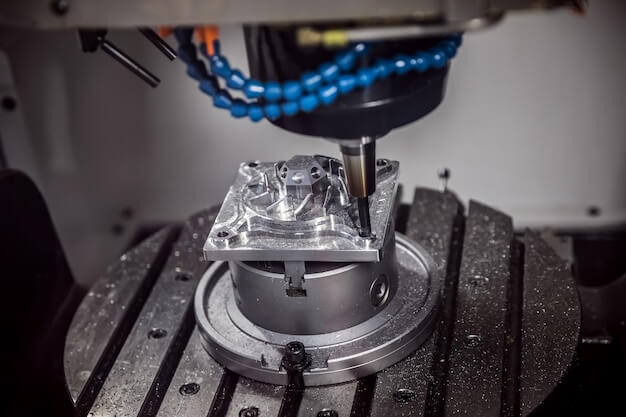

CNC Machining Materials Deep Dive: Acrylic vs. Polycarbonate for Transparent Parts Computer Numerical Control (CNC) machining is a production process that involves the use of computers to control machine tools, which helps in creating parts and components with high precision and accuracy. The choice of materials used in CNC machining significantly affects various aspects such […]

PEEK vs. ABS: A Guide to Choosing Injection Molding Materials

Understanding the Importance of Material Selection in Injection Molding Injection molding, a prevalent manufacturing method, requires meticulous attention towards selecting the appropriate material. The choice between materials such as PEEK and ABS can significantly impact not only the production process but also the attributes and applications of the final product. Both these thermoplastics have unique […]

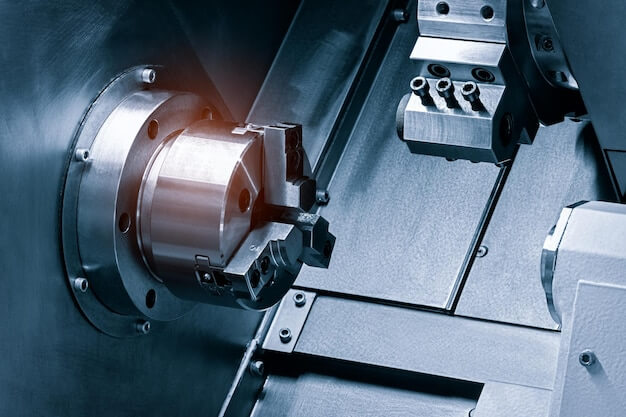

Optimizing Wear Resistance in CNC Parts: Compar

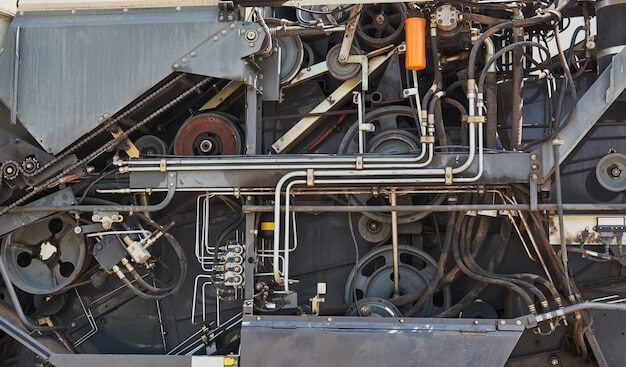

Introduction to CNC Parts and Wear Resistance CNC (Computer Numerical Control) parts play a pivotal role in modern manufacturing, enabling the production of complexly designed products with remarkable precision. Generally composed of diverse components like motors, drive systems, and computer interfaces, these subsystems collaboratively manipulate tools on multiple axes, efficiently shaping materials such as metal, […]

Understanding the Impact of Material Hardness on CNC Machining: Steel Grades Compared

Introduction to CNC Machining CNC machining, or Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It plays an integral role in creating intricate and detailed parts that are used across various industries including, but not limited to automotive, aerospace, medical, construction, and telecommunications. […]

Environmental Considerations in CNC Machining: Material Selection for Sustainable Manufacturing

Introduction to CNC Machining and its Environmental Considerations CNC machining is an advanced manufacturing process wherein pre-programmed software dictates the movement of factory machinery and tools. It is recognised for its precision, efficiency, and versatility in producing a wide array of objects ranging from car parts, surgical equipments to computer components. In spite of these […]

Polypropylene vs. Polyethylene: Understanding the Differences for Injection Molding

Introduction to Polypropylene and Polyethylene in Injection Molding Polypropylene (PP) and polyethylene (PE) are two common types of plastic materials used in the manufacturing industry. PP is a thermoplastic polymer utilized for various applications, owing to its resistance to numerous chemical solvents, bases, and acids. Meanwhile, PE is famed for flexibility, toughness, and ease of […]

Enhancing Aesthetic Appeal in CNC Machining: Anodized Aluminum vs. Painted Steel

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a high-precision manufacturing process that uses pre-programmed computer software to direct the movement of complex machinery tools. This technological approach proves extremely important and beneficial within various sectors of production given its ability to produce intricately designed parts with impeccable accuracy and precision. What makes […]

Ceramic vs. Metal Parts Manufacturing: Which is Best for Your Project?

Introduction to Parts Manufacturing and Material Selection The parts manufacturing industry is a broad portfolio that entails the construction of diverse machinery elements used in various settings, ranging from automobiles to home appliances. It’s an arena marked by sophistication, precision, and intricate attention since even slight variations from the desired specifications can potentially be detrimental. […]

SLS vs. SLA Materials: Choosing the Right 3D Printing Technology

Introduction to 3D Printing Technology and SLS vs SLA Materials In the world of manufacturing, 3D printing technology has emerged as a revolutionary tool with its ability to transform digital designs into physical objects. This procedure functions on an additive principle, assembling layers upon layers to create three-dimensional products. Amongst the multitude of 3D printing […]

3D Printing Resins: Standard vs. Engineering-Grade Options

Introduction to 3D Printing Resins In the vast field of additive manufacturing, 3D printing resins hold a significant place due to their unique properties and wide-ranging applications. These thermosetting materials have evolved from simple standards to advanced engineering-grade options that deliver exceptional results under diverse and challenging conditions. Esteemed for its versatility, this liquid raw […]

The Impact of Material Density on CNC Machining Costs and Efficiency

The Importance and Role of CNC Machining in Manufacturing CNC (Computer Numerical Control) machining is a critical element within modern manufacturing. As an advanced technology, it precisely automates the machinery processes, ranging from milling to lathing, through pre-programmed computer software. This accuracy significantly reduces errors, optimizes resource use, and ultimately improves productivity. Practical examples demonstrate […]