The Engineer’s Guide to Machining Composites: Challenges and Material Selection

Introduction to Machining Composites The process of machining composites, a field that utilizes a variety of substances with different properties skillfully merged to create a new material possessing unique characteristics. It encapsulates the application of various operations such as cutting, drilling, and grinding on composites to obtain desired shapes or finishes. Engineered composite materials stand […]

Guide to Selecting High-Performance Materials for CNC Machined Aerospace Components

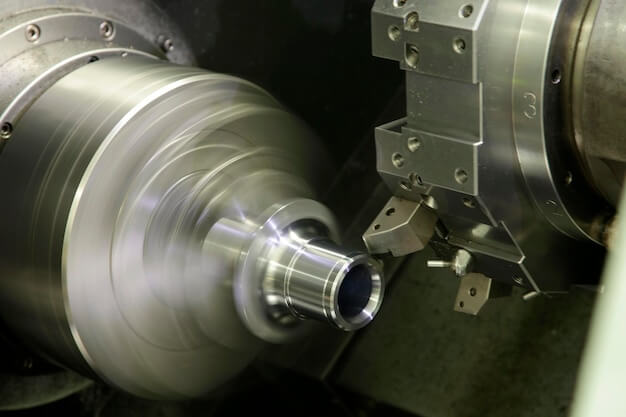

Understanding CNC Machining in the Aerospace Industry and the Importance of High-Performance Materials Selection The aerospace industry widely utilizes Computer Numerical Control (CNC) machining for manufacturing sophisticated components. This high precision production method ensures superior repetition, complexity and adherence to stringent tolerances that are essential for aerospace applications. However, successful CNC machining does not depend […]

The Battle of the Plastics: PVC vs. Polyurethane in Manufacturing

The Battle of the Plastics: PVC vs. Polyurethane in Manufacturing In the realm of manufacturing, two plastics dominate – Polyvinyl Chloride (PVC) and Polyurethane. PVC is one variant of plastic that has an extensive reach across various industrial sectors due to its hard but slightly flexible qualities. It’s extensively used for applications like construction of […]

Silicone vs. Plastic Injection Molding: Which Material Fits Your Product Best?

Introduction to Injection Molding In the manufacturing industry, injection molding is a commonly used technique. It is a process where material, either silicone or plastic, is heated until it melts and then forced into a mold, creating products in several shapes and sizes. Two major types of injection molding include silicone and plastic injection molding. […]

HDPE vs. LDPE: A Detailed Comparison for Manufacturers

Introduction: Understanding HDPE and LDPE In the realm of plastics, High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) play significant roles. HDPE is a rigid plastic material with an industrial strength robustness, offering high load-bearing capacity and impact resistance; these unique attributes make it ideal for heavy-duty applications such as water pipes, fuel tanks or outdoor […]

Navigating the World of Non-Metal CNC Machining: Wood vs. Plastic Material Insights

Introduction to CNC Machining: Special Focus on Wood and Plastic Materials CNC machining, or Computer Numerical Control machining, is a manufacturing process wherein pre-programmed computer software controls the movement of factory equipment and tools. It’s vastly beneficial for managing complex three-dimensional cutting processes. While this technique finds applications with an array of materials, our focus […]

The Battle of the Plastics: PVC vs. Polyurethane in Manufacturing

The Significance of Plastic in Manufacturing and The Contrast Between PVC and Polyurethane In the realm of manufacturing, plastic plays an indispensable role due to its versatility, durability, and cost-effectiveness. Among various plastics used, two types, namely Polyvinyl Chloride (PVC) and Polyurethane (PUR), are particularly prominent. As a thermoplastic polymer, PVC is recognized for its […]

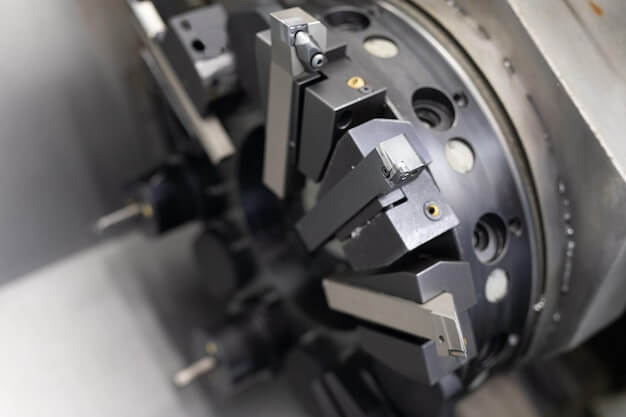

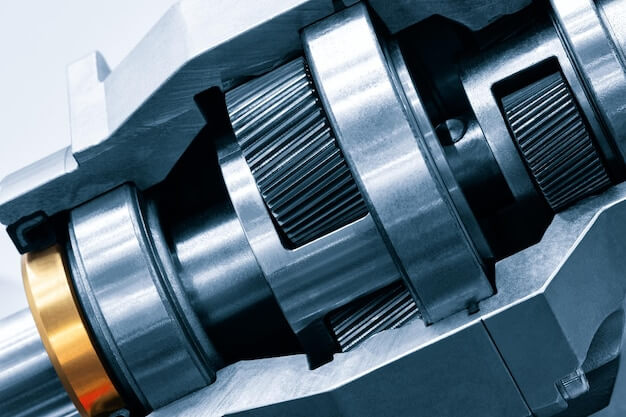

Choosing the Correct Material for High-Precision CNC Gear Machining

Introduction: Understanding CNC Gear Machining and The Importance of Material Selection The precision in gear manufacturing largely depends on Computer Numerical Control (CNC) technology – a systematic procedure implemented to manipulate the movements of factory machinery through programming. CNC gear machining specifically builds customized gears by cutting materials into exact dimensions with high accuracy and […]

The Art of CNC Machining: Aesthetic Materials for Consumer Products

Introduction to CNC Machining and its Aesthetic Significance in Consumer Products CNC Machining, known formally as Computer Numerical Control Machining, serves a significant role in producing consumer products. This technique uses computers to control machine tools for an accurate and efficient production process. The focus of this article touches upon the crucial use of aesthetic […]

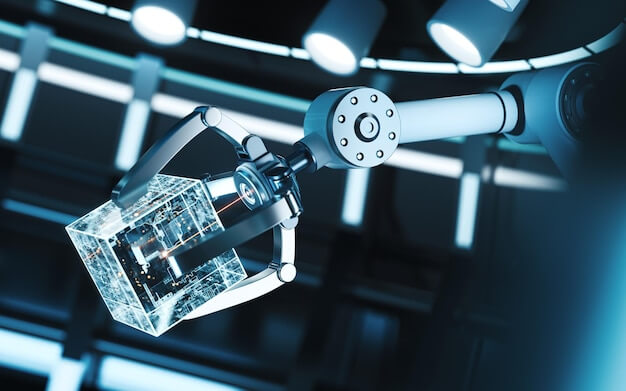

CNC Machining in Robotics: Material Selection for Durability and Functionality

Introduction: The Significance of CNC Machining in Robotics and the Importance of Material Selection The field of robotics has significantly benefited from the advancements in Computer Numeric Control (CNC) machining. This technology enables precision manufacturing that is essential for crafting intricate components without compromising quality or efficiency. Notably, material selection plays a vital role in […]

The Evolution of CNC Machining: Traditional vs. New Age Materials

Introduction to CNC Machining CNC machining stands for Computer Numerical Control machining, a process used extensively in modern manufacturing to control machine tools with computers. This method allows for the precise cutting, milling, and shaping of materials based on pre-programmed computer software. Its importance in manufacturing cannot be overstated, as it enhances efficiency, accuracy, and […]

ABS Plastic vs. Nylon: A Detailed 3D Printing Material Comparison

Introduction: The Importance of Material Selection in 3D Printing In the field of 3D printing, material selection plays a pivotal role in determining not only a product’s aesthetic quality, but also its functionality and durability. Different materials across the spectrum from ABS plastic to nylon offer unique advantages based on their distinct properties. ABS Plastic: […]