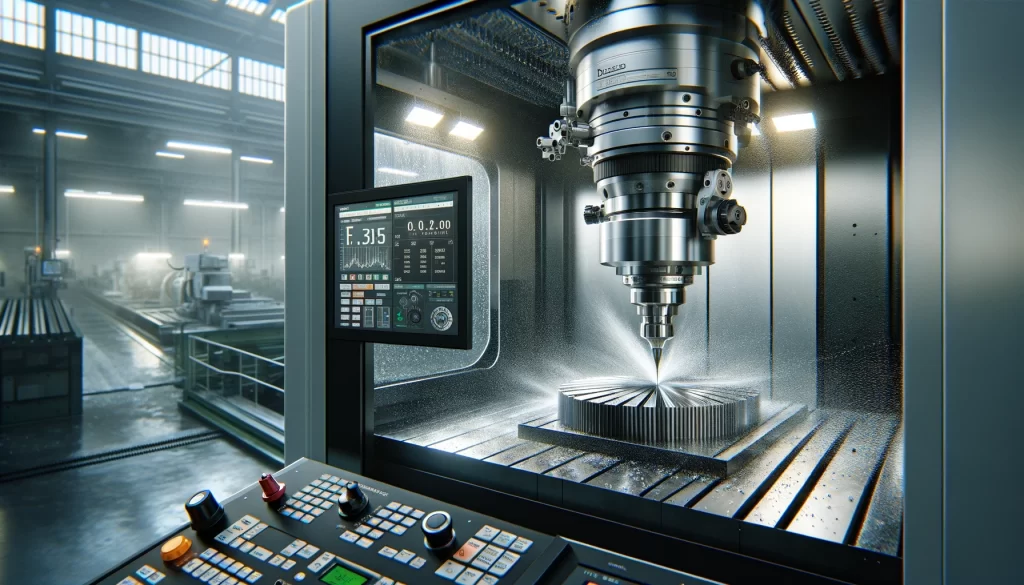

How Does High-Speed Milling Solve Common Issues in China CNC Machining Services?

What Are the Common Challenges Faced in CNC Machining in China? CNC machining in China, like in other manufacturing hubs, encounters several hurdles that can compromise efficiency, precision, and overall output quality. Key challenges include dealing with intricate designs that demand high precision, managing the high costs associated with material wastage, and overcoming the limitations […]

Mastering CNC Technology: Key Steps to Creating Efficient Thermal Bases

Introduction The realm of manufacturing has been profoundly transformed by the advent of Computer Numerical Control (CNC) technology, enabling the automation of machine tools with high precision and efficiency. Among the myriad of factors influencing the performance and outcome of CNC processes, thermal management stands out as a cornerstone for success. Efficient handling of the […]

Choosing Between Acrylic and Polycarbonate for CNC Machining: Clarity, Durability, and Machinability

Introduction to CNC Machining and Material Choices CNC machining, also known as Computer Numerical Control machining, is a critical aspect in the field of manufacturing. This process utilizes computerized controls to operate and manipulate machine tools, enabling accurate, consistent and quick production of complex parts across numerous sectors including automotive, aerospace, and medical industries. Central […]

Selecting the Right Plastic for CNC Machining: PC vs. PEEK

Introduction to CNC Machining and Material Selection CNC (Computer Numerical Control) machining plays a pivotal role in today’s manufacturing industry, facilitating precision part production through automated control of machine tools. Central to this process is choosing the right material — illustrated here with a focus on Polycarbonate(PC) and Polyether Ether Ketone (PEEK). PC, a thermoplastic […]

Choosing the Right Tool Steel for CNC Machining: D2 vs. A2

Introduction to CNC Machining and the Importance of Choosing the Right Tool Steel CNC Machining, or Computer Numerical Control Machining, is a manufacturing process where pre-programmed computer software controls the movement of factory machines and tools. This technique enables complex cuts in various materials with high precision. Crucial to this process’s efficacy is selecting appropriate […]

Polyethylene vs. Polypropylene in CNC Machining: A Material Comparison for Industrial Applications

CNC Machining and Material Overview: Polyethylene vs. Polypropylene Computer Numerical Control (CNC) machining is a manufacturing process utilized across various industries for its precision and versatility. It is an automated system where pre-programmed software controls the movement of factory machinery and tools, producing parts with high accuracy. In CNC machining, material selection plays a crucial […]

High-Speed CNC Milling: Comparing the Capabilities of Polycarbonate vs. Acetal (Delrin) in Precision Manufacturing

Introduction: Purpose of CNC Milling in Manufacturing and Overview of Polycarbonate and Acetal (Delrin) In the world of precision manufacturing, Computer Numerical Control (CNC) milling plays a vital role. Essentially, it fulfills the purpose of carving out intricate designs from solid materials such as metals or plastics with extreme accuracy. This process is automated and […]

What’s Vacuum Casting? Process, Design, and Applications

Introduction to Vacuum Casting Vacuum casting is a crucial manufacturing process, especially prevalent in the production of detailed and specific parts. It involves drawing liquid material into a mold under vacuum pressure before it solidifies to shape the end product. This method’s significance lies in its ability to reproduce fine details and accurate dimensioning from […]

Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a high-precision manufacturing process used in producing miniature and intricate plastic parts. This procedure, employing specialised machines with high-pressure moulding capabilities alongside minimal error margin, facilitates the production of micro-components, significantly smaller than one millimeter, highlighting its essence in the fabrication of small-scale technical components essential […]

Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is an advanced manufacturing technique that miniaturizes traditional injection molding processes. The principle of micro injection molding revolves around producing tiny, intricate components with extreme precision, using polymers or other thermoplastic materials. It enables complex shapes and configurations in the micron range which are widely used for […]

The Evolution of Injection Molding: Trends and Innovations

Introduction to Injection Molding Injection molding is a widely used manufacturing process in various industries, offering efficiency and versatility. This method involves injecting molten materials into a mold which then cools and solidifies to form the desired part or product. Adaptable to any shape or complexity, it has become an integral facet of sectors such […]

Cost-Effective Manufacturing Strategies for Small Businesses and Startups

Importance of Cost-Effective Manufacturing Strategies for Small Businesses and Startups The implementation of cost-effective manufacturing strategies is a critical component in the success of small businesses and startups. Operating with limited resources, they need to optimally utilize production processes that minimize costs while maximizing output. These strategies not only ensure business survival during challenging times […]