ABS Plastic vs. Nylon: A Detailed 3D Printing Material Comparison

Introduction to 3D Printing and the Importance of Materials The advent of 3D printing technology has revolutionized various industries by enabling rapid, flexible, and customized production. For beginners who are new to this fascinating world, 3D printing, also known as additive manufacturing, involves creating three-dimensional objects from digital blueprints, layer by layer. The material plays […]

HDPE vs. LDPE: A Detailed Comparison for Manufacturers

Introduction: An Overview of HDPE and LDPE In the plastics manufacturing industry, two commonly used materials are High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE). Both belong to the polyethylene family, a type of thermoplastic made from petroleum. HDPE: More rigid and robust than LDPE, HDPE is known for its strength and durability. It possesses high […]

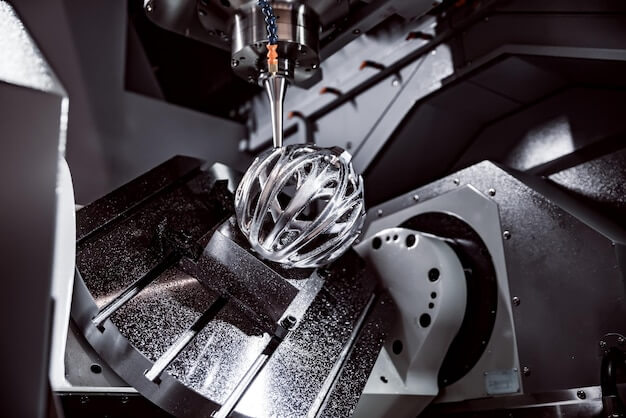

Eco-Friendly CNC Machining: Sustainable Materials and Practices

Eco-Friendly CNC Machining: An Introduction CNC (Computer Numerical Control) machining is a manufacturing process that commands the movement of factory machinery and tools using pre-programmed computer software, ensuring precise design production. This technique plays an indispensable role in modern manufacturing due to its accuracy, consistency, scalability, and versatility. Despite these advantages, however, traditional CNC machining […]

The Role of Surface Finishes in CNC Machining: Comparing Methods for Different Materials

Introduction to CNC Machining and Surface Finishes CNC machining, or Computer Numerical Control machining, is a pivotal process in modern manufacturing that leverages computerised controls to operate and manipulate machine tools. It allows for the precise construction of complex three-dimensional shapes with unparalleled accuracy. In this system, surface finishing plays an integral role as it […]

Brass vs. Copper in Custom Parts Manufacturing: A Comparative Analysis

Introduction to the Importance and Uses of Metals in Custom Parts Manufacturing In custom parts manufacturing, metals play a significant role due to their robustness, versatility, and adaptability. Frequent application involves producing machinery parts, hardware items, instruments, and countless other products. As different metals possess varied properties, understanding these differences is essential for optimizing output […]

CNC Machining Plastics: Delrin vs. Nylon for High-Precision Parts

Introduction to CNC Machining Plastics The Computer Numerical Control (CNC) machining process plays a vital role in manufacturing various high-precision parts and components. This advanced technology uses pre-programmed computer software to control the movements of factory tools and machinery for accuracy, efficiency, repeatability, and precision that manual operations cannot achieve. Among different materials used in […]

Graphene vs. Carbon Nanotubes: Future Materials in Manufacturing

Introduction: Understanding Graphene and Carbon Nanotubes in Modern Manufacturing In the rapidly evolving world of materials science, two pivotal elements currently dominating are graphene and carbon nanotubes. Derived from graphite, Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is renowned for its exceptional strength, conductivity, and flexibility. On the other hand, […]

Advanced Techniques in CNC Machining: Expert Insights Revealed

Introduction – Brief Overview of CNC Machining and Its Importance in Manufacturing CNC (Computer Numerical Control) machining stands as a fundamental pillar within manufacturing, transforming the industry with its unprecedented precision, efficiency, and repeatability. This automated process goes beyond manual intervention, commanding industrial tools to cut, shape, or finish materials based on pre-programmed instructions fed […]

CNC Turning Operations: A Comprehensive Overview

CNC Turning Operations: An Introduction and Its Significance in Manufacturing The CNC (computer numeric control) turning operations stand as a vital aspect of the modern-day manufacturing process. It is used for creating detailed, intricate designs in various materials like metal, plastic, or wood that are ordinarily challenging to perform manually. The applications of CNC turning […]

Silicone vs. Plastic Injection Molding: Which Material Fits Your Product Best?

Silicone vs. Plastic Injection Molding: An Overview Injection molding is a widely used method to produce parts from both silicone and plastic materials. To briefly elucidate, silicone injection molding involves heating up the raw material which then is injected into a mold under high pressure. As for plastic injection molding, granulated or powdered thermoplastic or […]

ABS Plastic vs. Nylon: A Detailed 3D Printing Material Comparison

Introduction: ABS Plastic and Nylon as 3D Printing Materials In the realm of 3D printing, two high-quality materials stand out: Acrylonitrile Butadiene Styrene (ABS) plastic and Nylon. Both have established themselves as durable and adaptable ingredients making them popular choices in myriad applications. Notably, ABS plastic is known for its robustness and resistance to high […]