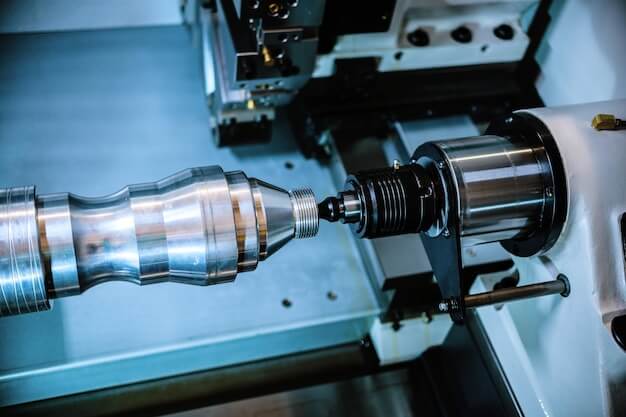

Analysis of processing difficulty of different materials in CNC processing

Introduction to CNC Processing and Material Selection CNC processing, a cornerstone of modern manufacturing, stands for Computer Numerical Control machining, a method where pre-programmed software commands the movement of factory tools and machinery. The selection of materials in CNC machining is critical; it not only influences the final product’s attributes but also affects the ease […]

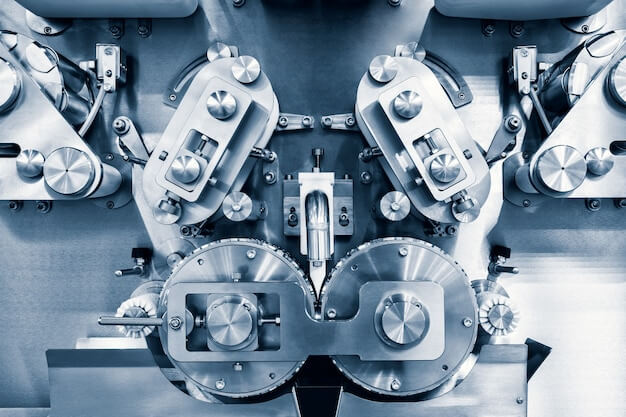

Micro Injection Molding: Principle, Benefits, and Applications

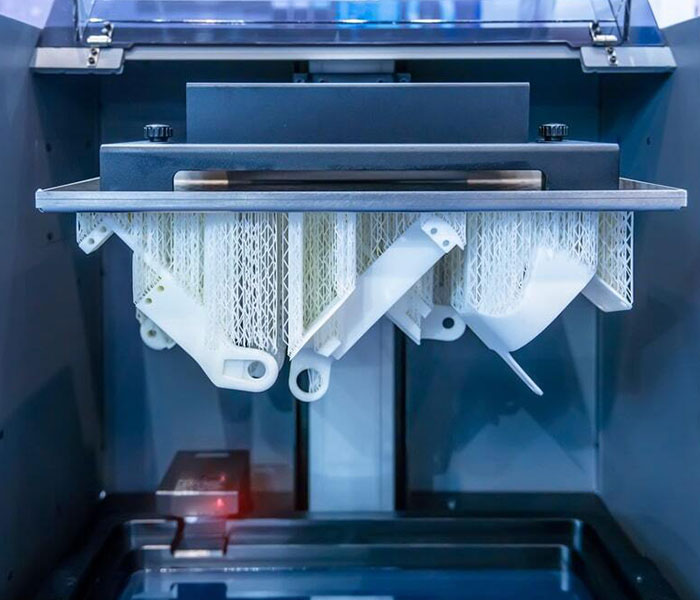

Introduction to Micro Injection Molding Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with precision. The process involves injecting thermoplastic or thermosetting polymers into a mold at high pressure, which results in the material conforming to the shape of the mold cavity. Unlike traditional […]

Understanding Delrin: A Comprehensive Guide to the Versatile Engineering Plastic

Understanding Delrin and the Role of Engineering Plastics Delrin, formally known as Polyoxymethylene (POM), is an engineering plastic renowned for its high tensile strength, rigidity, and resilience against friction and wear. This thermoplastic polymer consists primarily of carbon, hydrogen, and oxygen in a chain structure that provides remarkable stability and mechanical properties. The advent of […]

Acetal Polymers: Versatility and Applications in Modern Material Science

Introduction to Acetal Polymers Acetal polymers, often known under trade names such as Delrin, are highly crystalline thermoplastics characterized by their excellent mechanical strength, rigidity, and chemical resistance. These polymers are comprised of repeating units formed through the polymerization of formaldehyde or other cyclic ethers, resulting in a backbone with unique, stable acetal linkages (-C-O-C-). […]

Material properties of delrin

Introduction to Delrin Delrin, a trademark of DuPont, is a crystalline plastic known for its high tensile strength, stiffness, and enhanced dimensional stability. A type of acetal resin or polyoxymethylene (POM), Delrin boasts low friction and excellent wear resistance under wet conditions. Its properties make it ideal for gears, bushings, and small moving parts in […]

The use of plastics in food processing machinery

Introduction to Plastics in Food Processing Machinery The incorporation of plastics into food processing machinery plays a pivotal role in the modern food industry. These synthetic materials are employed for their versatility, durability, and cost-effectiveness, contributing significantly to the efficiency of production lines. Plastics offer numerous benefits including reduced weight, which eases the handling of […]

The role of polyester materials in engineering processes

Introduction to Polyester Materials in Engineering Polyester materials play a crucial role in various engineering applications due to their versatility, durability, and resistance to many chemicals. As synthetic polymers, polyesters are formed through a chemical reaction known as polymerization, where ester groups are linked together to create long molecular chains. These materials exhibit important properties […]

What material is delrin

Introduction to Delrin Delrin, also known as Polyoxymethylene (POM), is an engineering thermoplastic commonly used in precision parts that require high stiffness, low friction, and excellent dimensional stability. Recognized for its durability, it serves as a metal substitute due to these desirable attributes. Delrin is widely utilized in applications like gears, bushings, bearings, electrical insulating […]

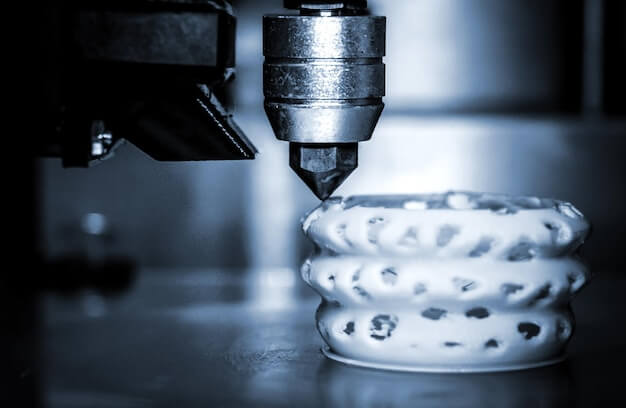

PETG vs. PLA: Differences and Comparison

Introduction to 3D Printing Filaments: PETG and PLA At the heart of 3D printing technology lies an essential element known as filament, which is the thermoplastic feedstock for fused deposition modeling (FDM) printers. Amongst the plethora of materials available, two stand out for their popularity and versatility: Polyethylene Terephthalate Glycol-modified (PETG) and Polylactic Acid (PLA). […]

Know Your Materials: Delrin

Introduction to Delrin Delrin, Polyoxymethylene (POM), known for its high tensile strength and durability, stands out in the realm of thermoplastics. Its molecular structure showcases a series of -CH2O- units, deriving from its formaldehyde polymer base. As an engineering plastic, Delrin is prized for resilience; resistance to friction, wear, and moisture adds to its unique […]

design for 3d printing how to reduce your cost

Relevance and Benefits of Cost Reduction in 3D Printing In an era where innovation is pivotal, 3D printing emerges as a transformative force across numerous industries, from manufacturing complex aerospace components to creating bespoke medical devices. However, the cost associated with this technology can often be a barrier to entry or expansion. Minimizing expenses in […]

Delrin in CNC machining technology

Delrin, a trademarked name for polyoxymethylene (POM), is an engineering thermoplastic known for its high strength, rigidity, and resistance to friction and wear. This semi-crystalline plastic boasts exceptional dimensional stability and ease of machining, making it a favored material in precision parts manufacturing. In the realm of CNC machining—a computer-controlled subtractive process used to create […]