Unveiling the Process of Bead Blasting in CNC Machining(sheet metal fabrication Tiffany)

Bead blasting, a critical part of the computer numerical control (CNC) machining process, has revolutionized how industries approach surface finishing. Often destructured to improve its aesthetics or performance, the finish of a product can greatly impact how it’s received by the end-user. This article will delve further into understanding bead blasting within the realm of […]

Exploring CNC Turning and Different Types of Rivets(cantilever snap joint Nicholas)

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry in ways few could have imagined. Among several processes, CNC turning stands out as both a cost-effective and efficient method to produce high precision parts needed across multiple industries. On the other hand, rivets – a reliable type of permanent mechanical fastener- have an array […]

The Intricacies of Bead Blasting in CNC Machining(non ferrous metals Nigel)

CNC (Computer Numerical Control) machining is a versatile manufacturing method that streamlines many industries today. It consists of various additive and subtractive processes necessary to design, construct, mold, or modify numerous materials. One such methodology increasingly becoming significant in the realm of CNC machining is ‘bead blasting.’ This article delves into the intricacies of bead […]

Demystifying Bead Blasting in CNC Machining(thermoplastic Kim)

In the ever-expanding world of computer numerical control (CNC) machining, there are numerous processes designed to enhance and perfect the final product. One such technique that has gained significant attention is bead blasting. This article will delve into what bead blasting entail, its benefits, applications, and why it’s integral to the CNC machining process. Bead […]

Understanding Bead Blasting in CNC Machining(china machining Avery)

Bead blasting, a compelling term in the world of Computer Numerically Controlled (CNC) machining, is an influential process that plays a transformative role in optimizing and enhancing parts’ aesthetic and functional quality. It involves propelled bead material against a part’s surface under high pressure to achieve different desired results, from removing imperfections and contaminants to […]

Exploring Bead Blasting in CNC Machining(3d prototyping James)

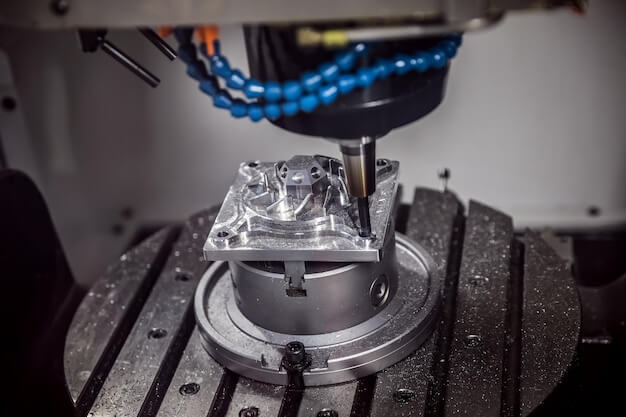

Bead blasting is a surface treatment process extensively used within the field of Computer Numerical Control (CNC) machining, which has revolutionized manufacturing industries. This method comes under focus due to its significant contribution to enhancing product quality by improving finish and extending lifespan. CNC machining refers to the use of computers to control machine tools […]

Bead Blasting: Unveiling the Integral Process in CNC Machining(chamfer Zoe)

In the world of Computer Numerical Control (CNC) machining, bead blasting is an indispensable process that plays a vital role in producing high-quality products. As customers and businesses strive for precision and accuracy, incorporating this method into machining practices can significantly enhance the product’s final look and feel. Understanding Bead Blasting Bead blasting refers to […]

The Intricacies of Bead Blasting in CNC Machining(cnc machining china Antonio)

CNC (Computer Numerical Control) machining stands as a cornerstone in the world of manufacturing. It is an innovative technology that has revolutionized the entire spectrum of creating precise, quality and intricate details on substances varying from metal to plastic. One particular technique within this field that warrants attention is bead blasting. Bead blasting is essentially […]

The Intricacies of Bead Blasting in CNC Machining(tack weld George)

In the realm of manufacturing and fabrication, efficient and effective finishing methods can make all the difference. One such process that has been gaining traction is bead blasting—an integral part of Computer Numerical Control (CNC) machining. This article seeks to delve into the specifics of this technique, its applications, benefits, and procedures involved in carrying […]

Unraveling Bead Blasting in CNC Machining(cnc laser cutting Geoffrey)

CNC machining continues to be a crucial player in manufacturing due to its ability to produce complex, high-quality parts on a large scale. One of the techniques applied within this versatile operation is bead blasting – a popular surface finish technique used to improve part aesthetics and functionality. Bead blasting, though seemingly straightforward, entails intricate […]

Understanding Bead Blasting in CNC Machining(thermoplastic Lambert)

CNC machining or Computer Numerical Control has been a game-changer in the manufacturing industry. In CNC, pre-programmed software controls machine movements leading to enhanced speed, precision, repeatability and notably reduced human interaction. There exist various processes within CNC but one integral procedure is bead blasting. Bead blasting involves directing high-pressure streams of glass beads towards […]

Understanding Bead Blasting in CNC Machining(cnc g code Jacqueline)

CNC (Computer Numerical Control) machining is a dominant method employed for multiple manufacturing systems across the globe. From healthcare to aerospace, this technology has revolutionized how we manufacture products. One revolutionary process within CNC machining is ‘bead blasting’. Bead blasting is an essential finishing technique used in CNC machining processes. It offers matchless surface finish […]