Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We needed durable, corrosion-resistant fasteners for an outdoor piece of equipment, and standard steel screws weren’t cutting it.Within a few weeks, they began to show signs of rust.That’s when I decided to explore custom Stainless Steel Screws produced […]

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing mechanical assemblies, I’ve learned one critical truth: the smallest parts often make the biggest difference. Fasteners—especially stainless steel fasteners—are a perfect example. Designers and CNC machinists regularly underestimate how critical the choice of fasteners can […]

Mastering Machining of Galvanized Steel: Techniques, Challenges & Solutions

Chapter 1: Introduction – Understanding Galvanized Steel and Machining Galvanized steel is everywhere around us. From the cars we drive to the buildings we live in, galvanized steel is a trusted material. It offers excellent corrosion resistance, durability, and strength. I’ve personally dealt with galvanized steel for years in various machining applications. Initially, I thought […]

Titanium vs Steel In Machining, Manufacturing, and Engineering: A Complete Guide to Strength, Weight, and Durability

I chose this title because I wanted to provide a comprehensive overview of titanium vs steel and how each material performs in machining, manufacturing, and engineering contexts. I’ve worked with both metals on various projects, from aerospace components to everyday consumer goods. Over time, I came to see how “titanium vs steel” remains a top question among […]

How to Machine Manganese Steel? Learn Properties, Best Practices, Challenges, and Solutions

Chapter 1: Introduction to Manganese Steel When I first started working in the machining industry, manganese steel immediately caught my attention. The name itself, “Manganese steel,” appeared frequently in machining forums, discussions, and among colleagues. Initially, I wondered: what exactly makes Manganese steel different from standard steel alloys, and why does it come up so […]

Tungsten Steel: The Ultimate Guide for Manufacturing, Tooling, and High-Performance Applications

Chapter 1: Introduction – What is Tungsten Steel? When I first encountered tungsten steel, I assumed it was just another strong metal alloy. After working in manufacturing for several years, I’ve come to appreciate how unique and vital tungsten steel truly is. Tungsten steel is an alloy primarily composed of tungsten (W) and carbon (C), commonly […]

Alloy Steel Machining Insights: Your One-Stop Guide to Superior Results

Introduction I’ve always found “alloy steel” to be a fascinating subject. There’s so much depth to it, from its versatile chemical composition to the countless industrial applications that rely on its exceptional properties. When we talk about alloy steel, we’re talking about a category of steel that has been enhanced through the addition of various alloying […]

316 Stainless Steel Machining: Best Tools, Cutting Speeds, and Techniques

Introduction I’ve worked with all kinds of metals in various shops. Over time, I’ve come to see why 316 stainless steel is so widely used. It’s sturdy, corrosion-resistant, and can handle many demanding environments, like marine applications or food-processing lines. Whenever I think about machining 316 stainless steel, I remember the first time I tried to cut it […]

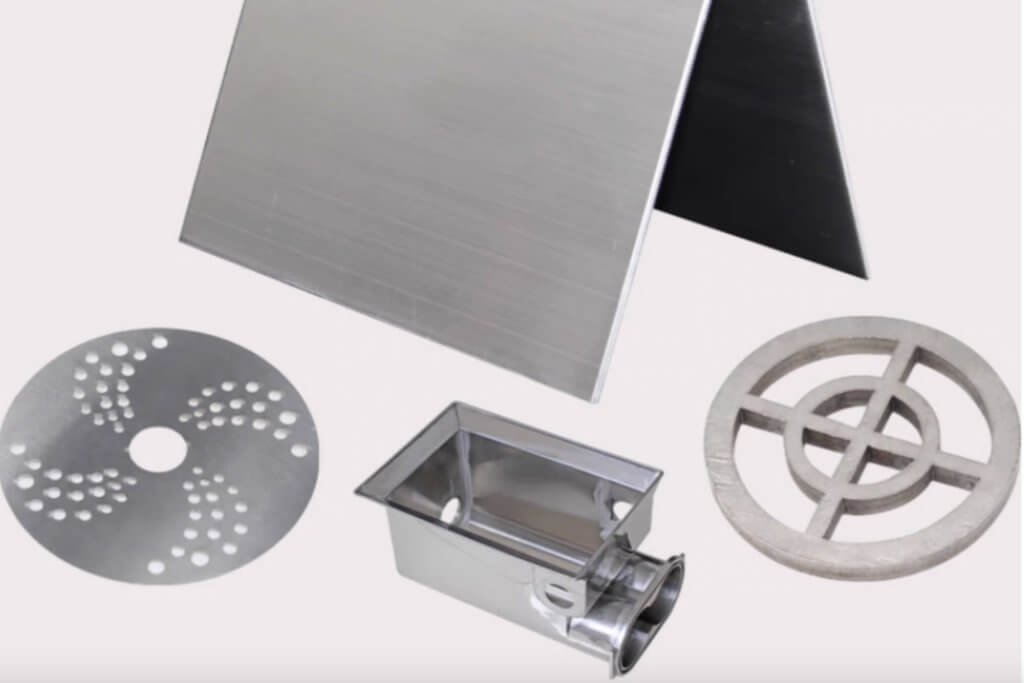

304 Stainless Steel: Properties, Applications, Machining, and Buying Guide

Introduction I still recall the day I had to choose a material for a small test project back when I was just starting out in fabrication. My mentor insisted on using 304 stainless steel, even though I had initially considered a cheaper alloy. At the time, I only vaguely knew that 304 stainless steel was […]

Galvanized Square Steel and CNC Machining: The Ultimate Guide

Introduction If you’re involved in construction, metal fabrication, or precision machining like me, you’ve probably encountered galvanized square steel. Galvanized square steel is popular due to its strength, corrosion resistance, and versatility. From structural frames and fencing to decorative architectural features, it offers reliable performance across various applications. Many industries rely on custom machining to produce precise components […]

VG10 Steel and CNC Machining: The Ultimate Guide

Introduction If you’re in manufacturing, custom knife making, or precision machining like I am, you’ve probably heard about VG10 steel quite often. VG10 steel is well-known in the knife-making world for its impressive edge retention, toughness, and resistance to corrosion. I’ve personally seen how custom machining can significantly improve the functionality and aesthetics of VG10 steel products. In this […]

AR500 Steel Meets CNC: Your Questions Answered

Introduction: Got Questions About AR500 Steel and CNC? We’ve Got Answers Got a question about machining AR500 steel with CNC? You’re in the right place. AR500 steel is tough stuff—hard, durable, and perfect for things like shooting targets or heavy machinery parts. Pair it with CNC machining, and you’ve got a combo that’s all about […]