How to Choose the Right Surface Finish Techniques for Precision CNC Machining of Food Automation Machinery?

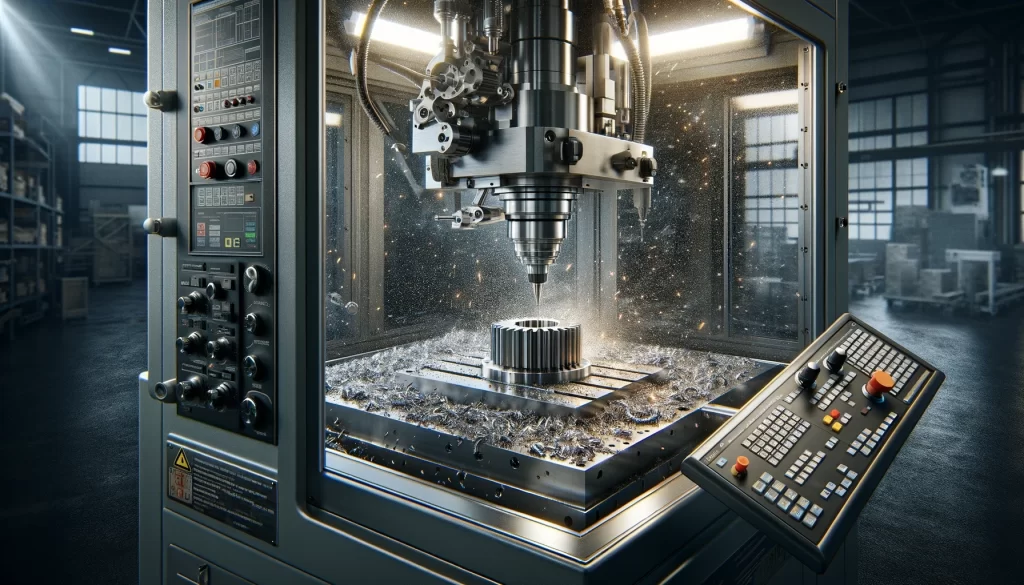

Surface Finish in Precision CNC machining Precision CNC machining plays a pivotal role in manufacturing components for food automation machinery. The surface finish of these components is crucial not only for the machinery’s performance but also for its compliance with strict food safety standards. This article explores the essential factors for selecting the most appropriate […]

What Materials Are Best Suited for CNC Machined sprockets in Food Automation Systems?

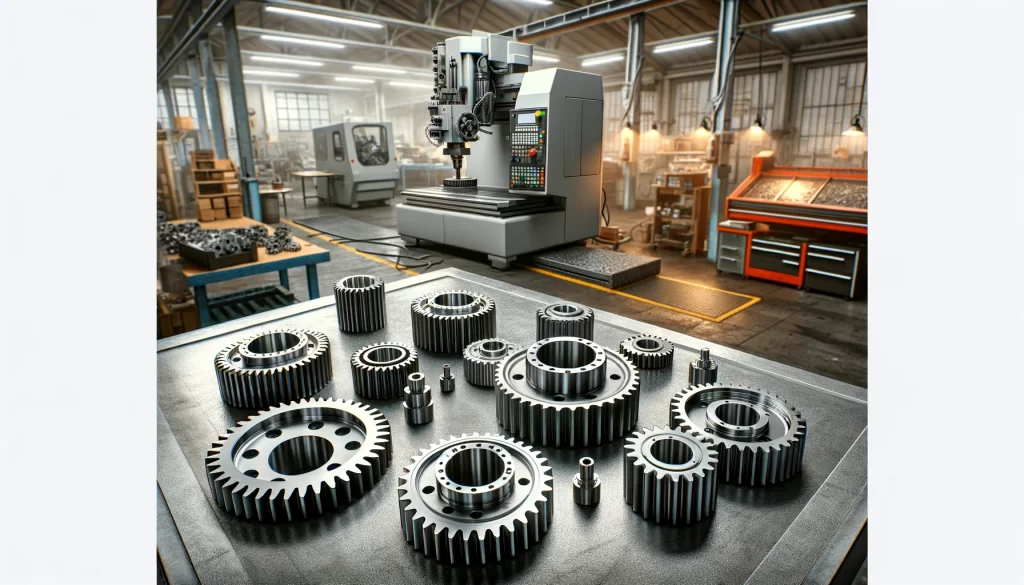

Selection of Materials for sprockets in Food Automation Systems The rapidly evolving field of food automation demands components that combine precision, efficiency, and unwavering adherence to safety standards. CNC machined sprockets, integral to the movement and functionality of food processing equipment, must be manufactured with materials that not only endure the mechanical rigors of operation […]

How Can Precision CNC Machining Improve the Durability and Performance of Sprockets in Food Automation Systems?

What Materials Are Best Suited for CNC Machined Sprockets in Food Automation Systems? Precision CNC Machining can improve the Durability and Performance of Sprockets in Food Automation Systems.When selecting materials for CNC machined sprockets that will be used in food automation systems, manufacturers must consider several critical factors. These include the material’s mechanical properties, compatibility […]

What Precision Techniques Are Crucial for CNC Machining of Fastening Rings in Food Machinery?

Precision CNC Machining in Food Machinery Precision CNC machining has become a cornerstone in manufacturing components for food machinery due to its ability to produce highly accurate and consistent parts. Fastening rings, crucial for ensuring tight seals in food processing equipment, require the highest level of precision to avoid any contamination risks and maintain machinery […]

What Challenges Does Precision CNC Machining Overcome in Thread Milling for Food Automation Machinery Ball Screws?

Understanding Thread Milling in Precision CNC Machining Precision CNC machining stands as the cornerstone of modern manufacturing, particularly in the intricate process of thread milling for ball screws used in food automation machinery. As the demand for high-quality, efficient components grows, so too does the necessity for precision in every aspect of production. Thread milling […]

What Are the Key Considerations When Designing Toolpaths for Precision CNC Machining of Rails?

Introduction to Precision CNC Machining of Rails Precision CNC machining is indispensable in rail manufacturing, where exacting standards for dimensions, tolerances, and profiles are paramount. This technology enables the production of highly accurate rail components essential for the operational safety and efficiency of train systems. The introduction of CNC technology in rail production has revolutionized […]

How Do CNC Machining Techniques Affect the Accuracy of Mold Designs

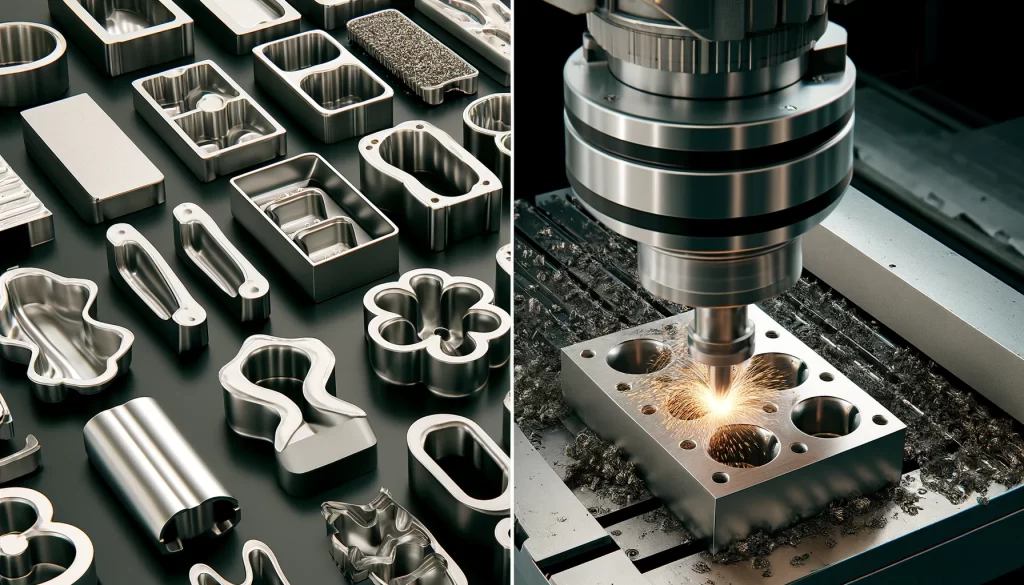

Introduction to CNC Machining and Mold Design CNC (Computer Numerical Control) machining is a critical component of modern manufacturing, offering precision that is essential for the production of complex molds. The effectiveness of CNC machining in mold design stems from its ability to produce components with extremely tight tolerances and consistent repeatability across high volumes […]

How Does the Use of CNC Machining Parts in Molds Improve the Performance of Food Automation Machinery?

Introduction CNC (Computer Numerical Control) machining has revolutionized the manufacturing world with its precision and versatility, especially in producing complex parts for various industries. In the realm of food automation machinery, the use of CNC machining parts in molds plays a crucial role in enhancing production efficiency, ensuring product consistency, and adhering to strict hygiene […]

What Are the Key Technical Details in CNC Machining of Conveyor Screws?

Introduction to CNC Machining of Conveyor Screws Conveyor screws, also known as screw augers, play a pivotal role in a variety of industries including agriculture, food processing, pharmaceuticals, and mining. These components are essential for the efficient handling and processing of materials, making precision in their manufacture critical. CNC (Computer Numerical Control) machining offers a […]

How Does China CNC Machining Service Address the Challenges of Specialty Alloys in Food Automation Machinery?

Introduction to CNC Machining and Specialty Alloys CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, offering unparalleled precision and efficiency. In China, where manufacturing capabilities are vast, CNC machining services have evolved to meet diverse industry demands, especially in the food automation sector. Specialty alloys, crucial for their durability and corrosion […]

What Makes Chinese CNC Machining Ideal for Producing Food Automation Machinery Shafts

Introduction to CNC Machining in China China’s prowess in manufacturing has grown significantly, with CNC machining at the forefront of its industrial capabilities. CNC (Computer Numerical Control) machining is a process used extensively in the production of precision components, and its adoption in China has been pivotal for the country’s manufacturing sector. This section explores […]

How Do Chinese CNC Machining Services Enhance the Production Efficiency and Precision of Dough-Cutting Blades in Food Forming Machinery?

Introduction to CNC Machining in the Food Industry CNC (Computer Numerical Control) machining has revolutionized manufacturing across various industries, including the food sector. Its precision, efficiency, and versatility make it ideal for producing complex components like dough-cutting blades used in food forming machines. These blades are crucial for ensuring consistent shape and size of food […]