Advantages of Using Beryllium Copper in CNC Machining Applications

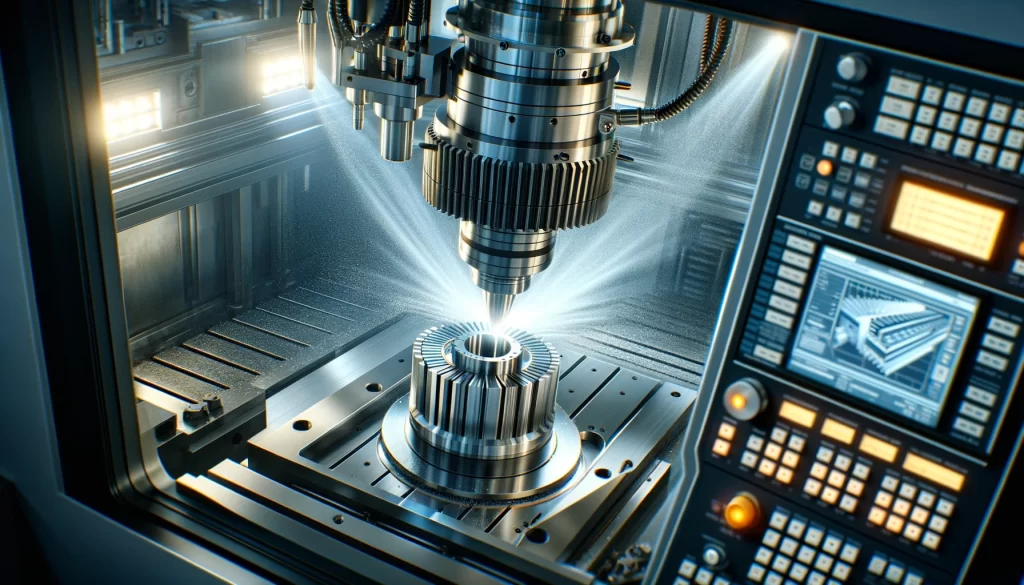

Introduction to Beryllium Copper and CNC Machining Beryllium copper, often referred to as beryllium bronze or spring copper, is a strong, corrosion-resistant, and highly conductive metal alloy. Notably, it contains approximately 0.5-3% beryllium by weight with the remainder largely consist of copper. It’s admired in various industrial applications due to its non-magnetic and non-sparking properties. […]

CNC Machining and the Aerospace Industry: Rene 41 vs. Waspaloy Material Considerations

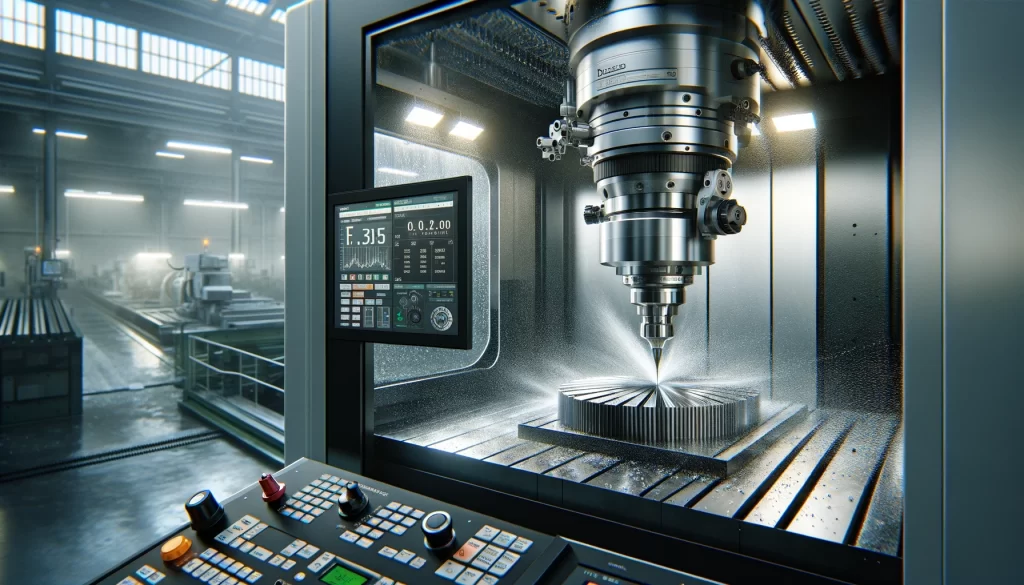

CNC Machining and its Crucial Role in AeroSpace Industry with Rene 41 & Waspaloy Materials Computer Numerical Control (CNC) machining plays a crucial role in the aerospace industry as it provides unprecedented precision, flexibility and efficiency in manufacturing complex components. Two materials frequently used are Rene 41 and Waspaloy owing to their robust characteristics suitable […]

How Can Startups Leverage China Custom Machining for Ultra-Precision Engineering Solutions

What Are the Key Technologies Driving Ultra-Precision in China’s Custom Machining? In the realm of custom machining, achieving ultra-precision is not just a matter of skill but also a testament to the technological prowess embedded within the machining equipment and processes. China, being a hub for manufacturing and custom machining, has been at the forefront […]

How Does High-Speed Milling Solve Common Issues in China CNC Machining Services?

What Are the Common Challenges Faced in CNC Machining in China? CNC machining in China, like in other manufacturing hubs, encounters several hurdles that can compromise efficiency, precision, and overall output quality. Key challenges include dealing with intricate designs that demand high precision, managing the high costs associated with material wastage, and overcoming the limitations […]

How is China CNC Machining Service Revolutionizing the Production Process of PCB Separators?

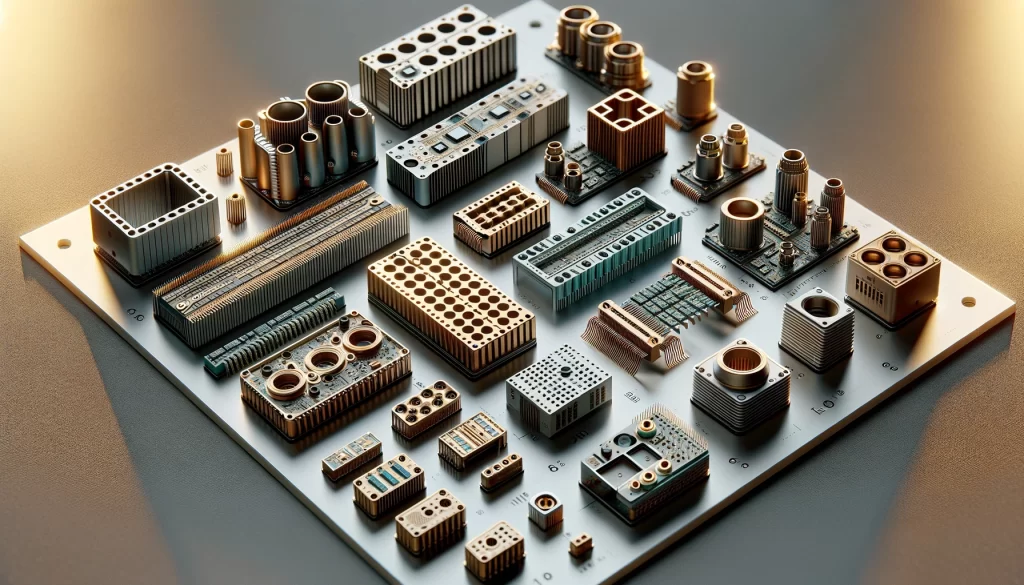

What Are the Cutting-Edge CNC Technologies Employed in China for PCB Separator Production? The realm of CNC machining in China is undergoing rapid transformation, particularly in the production of PCB Separators. Advanced technologies such as high-speed milling, ultra-precision machining, and adaptive control have been at the forefront. These innovations allow for unparalleled accuracy and efficiency […]

Mastering CNC Technology: Key Steps to Creating Efficient Thermal Bases

Introduction The realm of manufacturing has been profoundly transformed by the advent of Computer Numerical Control (CNC) technology, enabling the automation of machine tools with high precision and efficiency. Among the myriad of factors influencing the performance and outcome of CNC processes, thermal management stands out as a cornerstone for success. Efficient handling of the […]

Challenges and Solutions in CNC Machining of Custom Connectors

Introduction The art of CNC machining has become indispensable in the fabrication of custom connectors, components pivotal in numerous industries for their ability to ensure reliable and efficient electrical and data connections. This intricate process, however, is fraught with challenges, ranging from the selection of appropriate materials and maintaining tool integrity to achieving unparalleled precision […]

CNC Machining for Aerospace Applications: Titanium vs. Aluminum Alloys

CNC Machining in Aerospace: An Introduction and Overview Computer Numerical Control (CNC) machining is a manufacturing process that utilizes software-directed machines to fabricate complex parts with high accuracy and repeatability. Being able to program the machine’s movements allows for precise control, enabling a level of detail that would be difficult to achieve manually. This characteristic […]

The Efficiency of CNC Machining: Titanium vs. Steel for High-Performance Components

Introduction to CNC Machining and Material Selection Computer Numerical Control (CNC) machining revolutionizes the manufacturing space by enabling highly accurate, repeatable, and complex component production. In high-performance industries like aerospace and automotive, precision and reliability are vital, making CNC machining an indispensable solution. However, the success of this process pivots around one critical factor – […]

The Role of Surface Finishing in CNC Machined Parts: Anodizing Aluminum vs. Electroplating Steel

The Role of Surface Finishing in CNC Machined Parts: Introduction and Background Knowledge Surface finishing, integral to the manufacturing process, is a group of industrial procedures employed on the outer surface of machined parts for enhancing their functional or aesthetic properties. This can include improving durability, corrosion resistance, chemical compatibility, and overall performance. It involves […]

CNC Machining Aluminum vs. Brass: A Detailed Comparison for Precision Parts Manufacturing

CNC Machining: Aluminum vs. Brass in Precision Parts Manufacturing The continuous quest for efficiency and precision has made CNC (Computer Numerical Control) machining a vital process in the manufacturing of precision parts. By utilizing computer-programmed tools, CNC machining offers unprecedented accuracy, enabling manufacturers to produce intricate components with high dimensional tolerance. This introduction will concentrate […]

The Advantages of Using Molybdenum in CNC Machining Applications

CNC Machining Applications and the Role of Molybdenum Computer Numerical Control (CNC) machining is a revolutionary process transforming raw materials into intricate components. This cutting-edge approach automates control of machining tools, streamlining operations across various industries such as automotive, aerospace, and electronics. Complex parts can be produced swiftly with high precision and accuracy, eliminating potential […]