CNC Machining for Aerospace: Titanium Alloys vs. Aluminum – Performance and Cost Analysis

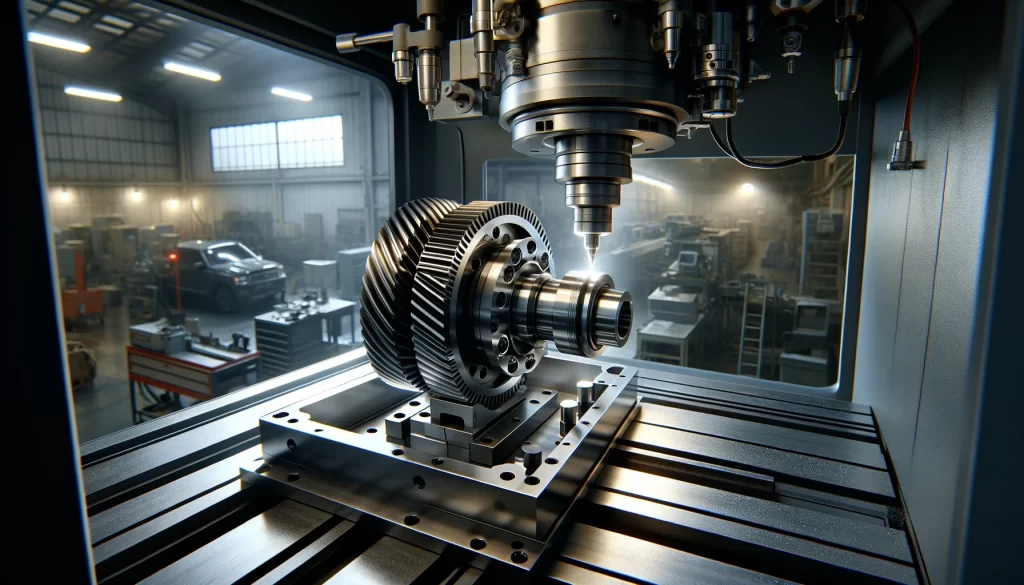

CNC Machining in the Aerospace Industry: An Introduction and Importance of Material Selection CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software directs the movement of factory machinery and tools. This technology has found prolific application within the aerospace industry due to its high precision, versatility and repeatability, making it ideal […]

Technical Challenges and Solutions in China Custom CNC Machining of Fasteners

Introduction: The Current State and Challenges of China Custom CNC Machining Fasteners In the realm of custom CNC machining, China stands as a pivotal player due to its extensive manufacturing capabilities and vast industrial landscape. The country’s prowess in producing a wide range of custom CNC machined fasteners is unrivaled. These components are crucial in […]

Step-by-Step Guide to CNC Machining Pulleys in China for Cost-Effectiveness

Introduction: Understanding the Value of CNC Machining in China CNC (Computer Numerical Control) machining stands as a cornerstone in China’s manufacturing sector, driving efficiency and precision in the production of complex components like pulleys. China’s embrace of CNC technology is evidenced by its widespread application across various industries, from automotive to aerospace. The precision and […]

CNC Precision in Crafting Bearing Shafts

Bearing shafts play a critical role in various mechanical systems, providing support and enabling smooth rotational movement. The precision required in crafting these components is paramount to ensure optimal performance and longevity. This article explores the significance of CNC precision in the manufacturing of bearing shafts, highlighting its role in achieving superior quality and functionality. […]

What’s Vacuum Casting? Process, Design, and Applications

Introduction to Vacuum Casting Vacuum casting is a crucial manufacturing process, especially prevalent in the production of detailed and specific parts. It involves drawing liquid material into a mold under vacuum pressure before it solidifies to shape the end product. This method’s significance lies in its ability to reproduce fine details and accurate dimensioning from […]

Maximizing Precision in CNC Machining: Techniques and Tips

Importance of Precision in CNC Machining Precision is an fundamental component in the field of Computer Numerical Control (CNC) machining. It entails producing parts that are not only accurate but also consistent, which is crucial for applications where even the smallest deviation can result in substandard performance or complete failure. A myriad of factors impact […]

Innovative Approaches to CNC Assembled Crankshafts by Leading China Machining Manufacturers

Introduction to CNC Machining in Crankshaft Production Computer Numerical Control (CNC) machining has become an integral part of the manufacturing industry, providing unparalleled precision, efficiency, and repeatability. In the realm of crankshaft production, the adoption of CNC technology is particularly significant among leading Chinese machining manufacturers, known for their commitment to innovation and excellence. The […]

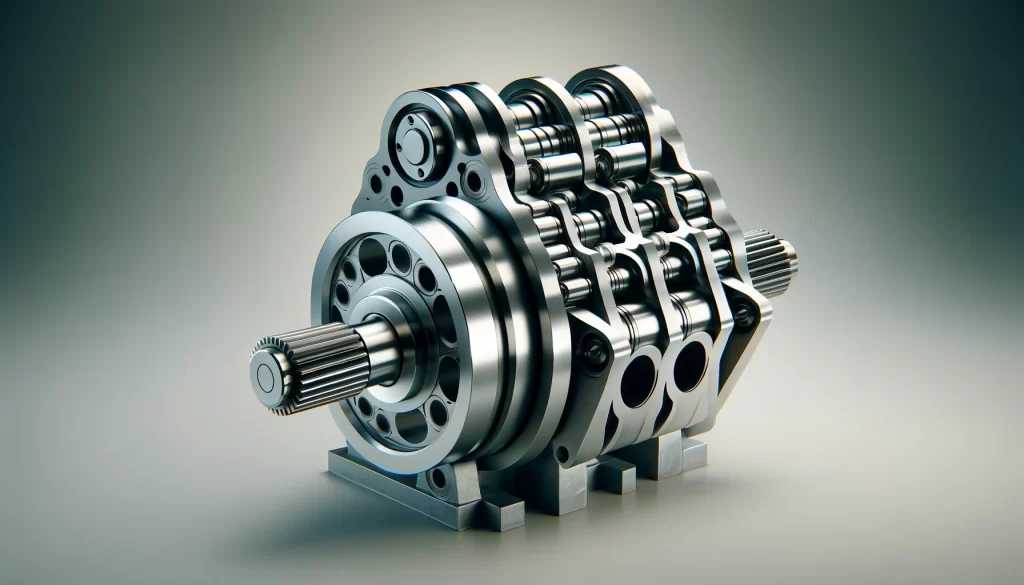

Material Selection and CNC Machining: Key Decisions in Rigid Coupling Manufacturing

Importance of Material Selection: The Basis of Rigid Coupling Material selection stands as a cornerstone in the manufacturing of rigid couplings, directly influencing their performance, durability, and application suitability. The choice of material affects not only the mechanical properties such as strength, hardness, and fatigue resistance but also factors like manufacturability, cost, and environmental impact. […]

Overcoming Common CNC Machining Challenges in Gear Rack Production: Tips from China’s Experts

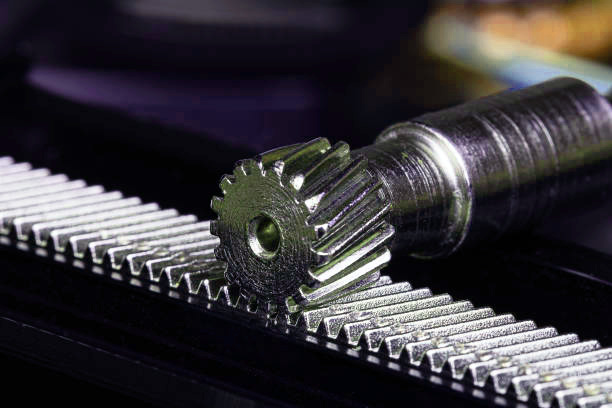

Precision Control Challenges: Strategies for Enhancing Machining Accuracy In the realm of CNC machining, precision is paramount, especially when it comes to the production of gear racks, where even the slightest deviation can lead to significant performance issues. The challenges in maintaining high levels of accuracy are multifaceted, stemming from tool wear, machine vibration, thermal […]

China Machining Manufacturer Insights: Overcoming Challenges in CNC Assembled Crankshaft Production

The Complexity of CNC Crankshaft Design in High-Performance Applications The intricate process of designing CNC crankshafts for high-performance engines encapsulates a range of challenges, primarily centered around achieving an optimal balance between durability and efficiency. The geometric precision required to ensure minimal vibration and maximal strength under the high loads of performance racing or aerospace […]

Navigating the Complexities of CNC Machining Assembled Crankshafts with China’s Top Manufacturers

Introduction to CNC Machining for Assembled Crankshafts CNC (Computer Numerical Control) machining represents a pinnacle of precision engineering, a process that has revolutionized the manufacturing world. Assembled crankshafts, which are at the heart of any engine, demand the utmost precision and care in their production. The processing requirements of the crankshaft are also very complex. […]

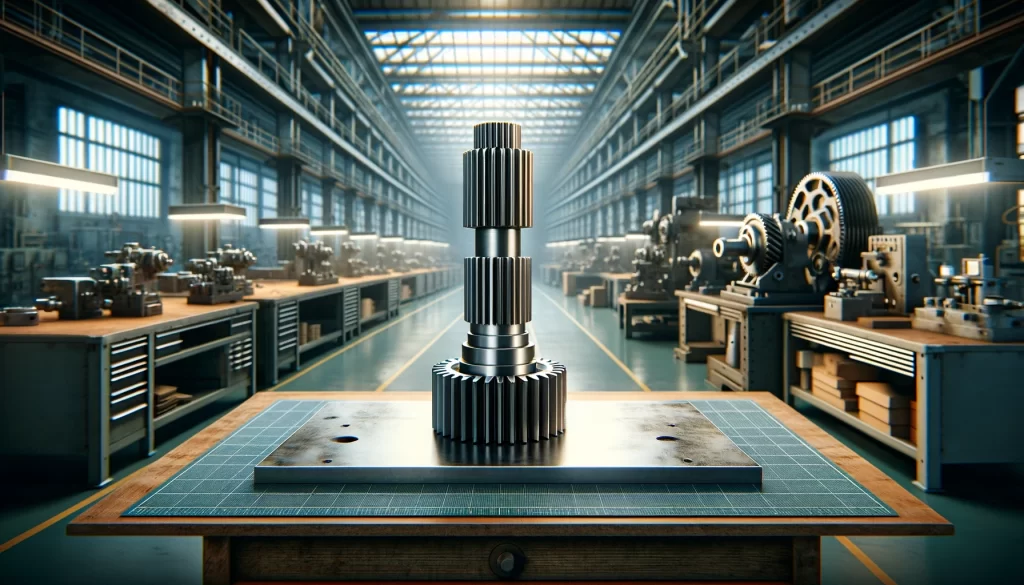

China’s CNC Craft: Gear Shafts Redefined

The Evolution of Gear Shaft Machining: A Historical Perspective The inception of gear shaft manufacturing dates back to the industrial revolution, but the most transformative era for this craft began with the advent of Computer Numerical Control (CNC) technology. Initially, gear shafts were created through manual processes that required the meticulous labor of skilled craftsmen. […]